Vacuum clean workshop

A clean and workshop technology, applied in the field of clean workshops, can solve the problems of inability to meet the needs of large-scale and rapid production of products and small production space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

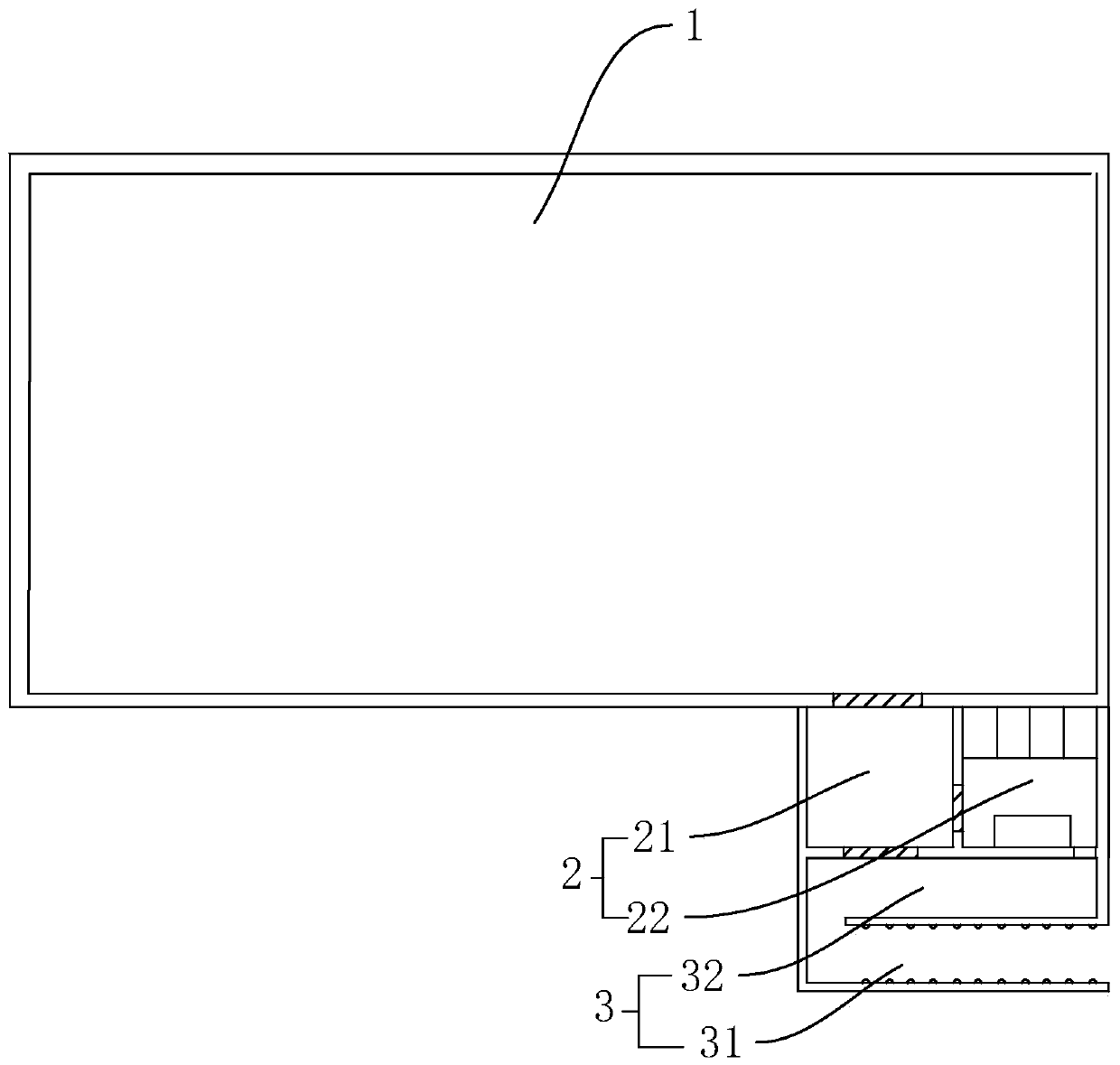

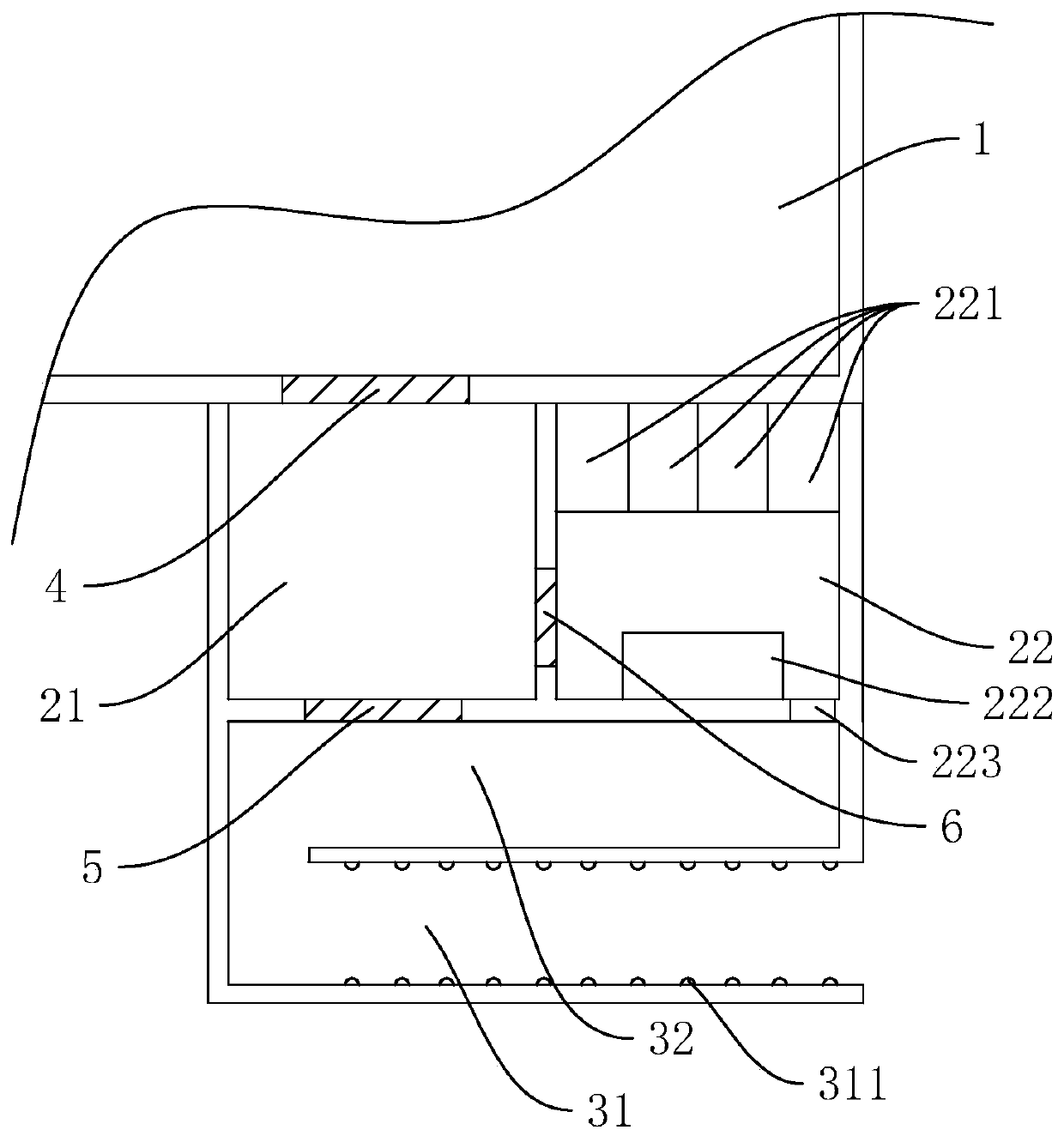

[0035] refer to figure 1 and figure 2 , is a vacuum clean workshop disclosed by the present invention, including a closed production section 1, an entry and exit transition section 2 connected to the production section 1, and a disinfection section 3 connected to the entry and exit transition section 2. The side of the transition zone 2 close to the production zone 1 is connected to the production zone 1 through the first airtight door 4 , while the side of the transition zone 2 close to the disinfection zone 3 is connected to the disinfection zone 3 through the second airtight door 5 . Both the production section 1 and the transition section 2 are equipped with vacuum pumps and gas supply pipes that send external air into the interior. Production section 1 uses the vacuum pump to create a vacuum environment inside the workshop to meet production needs. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com