Soluble hydroxyethyl modified cotton fiber fabric and preparation method thereof

A technology for soluble hydroxyethyl and fiber fabrics, which is applied in the field of medical soluble gauze, cotton fiber fabrics and their preparations, and soluble hydroxyethyl modified cotton fiber fabrics and their preparation fields, and can solve the problem that surgical hemostasis is difficult to grasp and dissolve. Fast speed and other problems, to achieve the effect of improving hemostasis operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

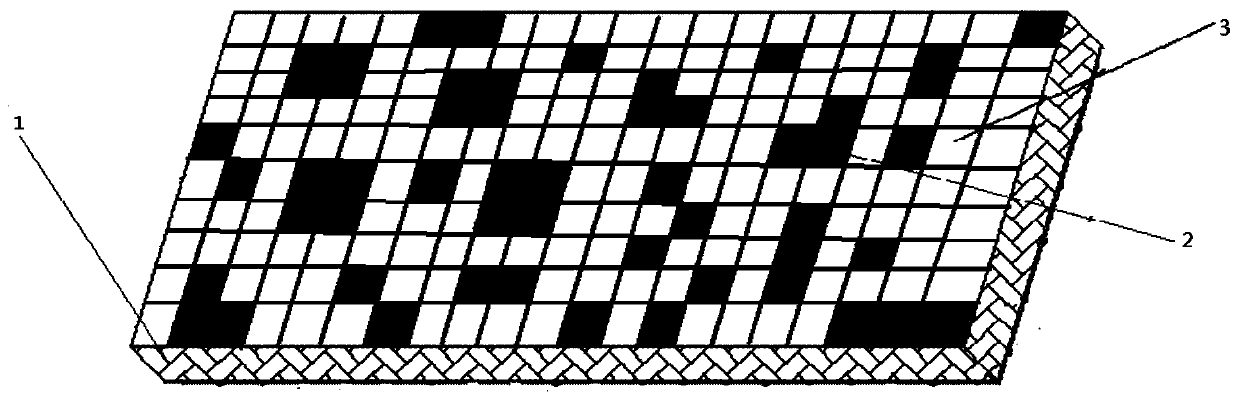

Image

Examples

Embodiment 1

[0041] (1) Preparation of water-soluble gauze

[0042] Degrease 300 grams of clean cotton, immerse it in 18-27% sodium hydroxide aqueous solution, react for 1-2 hours, take it out and place in a centrifuge to remove excess lye until the gauze contains 80-100% lye , Then put the deliquored yarn in a 10L rotary reactor, add 3500ml of 95% isopropanol, evacuate to -0.08Mpa, suck 540ml of ethylene oxide into the reactor several times, and rotate at 25℃ React for 20-24 hours, then neutralize the gauze with 66-120ml of acetic acid to make the pH 7-8, then wash the gauze with 95% ethanol until the sodium acetate content in the gauze is below 1%, and finally the washed gauze Place it in a constant temperature drying oven at 80°C and dry it to obtain 450g of water-soluble gauze. The time to completely dissolve in water is 30 seconds;

[0043] (2) Follow-up processing

[0044] The water-soluble gauze prepared in step (1) is subjected to needling treatment. The specific steps are as follows: p...

Embodiment 2

[0049] (1) Preparation of water-soluble gauze

[0050] Degrease 300 grams of clean cotton, immerse it in 18-27% sodium hydroxide aqueous solution, react for 1-2 hours, take it out and put it in a centrifuge to remove excess lye until the gauze contains 80-100% lye , Then place the deliquored yarn in a 10L rotary reactor, add 3500ml of 95% isopropanol, evacuate to -0.08Mpa, suck 750ml of ethylene oxide into the reactor several times, and rotate at 25℃ React for 20-24 hours, then neutralize the gauze with 66-120ml of acetic acid to make the pH 7-8, then wash the gauze with 95% ethanol until the sodium acetate content in the gauze is below 1%, and finally the washed gauze Placed in a constant temperature drying oven at 80°C and dried to obtain 540 g of water-soluble gauze. The time for complete dissolution in water is 20 seconds.

[0051] (2) Subsequent treatment of soluble hydroxyethyl modified cotton fiber fabric

[0052] The water-soluble gauze prepared in step (1) is subjected to ...

Embodiment 3

[0054] (1) Preparation of water-soluble gauze

[0055] Degrease 300 grams of clean cotton, immerse it in 18-27% sodium hydroxide aqueous solution, react for 1-2 hours, take it out and put it in a centrifuge to remove excess lye until the gauze contains 80-100% lye , Then place the deliquored yarn in a 10L rotary reactor, add 3500ml of 95% isopropanol, evacuate to -0.08Mpa, suck 750ml of ethylene oxide into the reactor several times, and rotate at 25℃ React for 20-24 hours, then neutralize the gauze with 66-120ml of acetic acid to make the pH 7-8, then wash the gauze with 95% ethanol until the sodium acetate content in the gauze is below 1%, and finally the washed gauze Placed in a constant temperature drying oven at 80°C and dried to obtain 540g of water-soluble gauze. The time for complete dissolution in water is 25 seconds.

[0056] (2) Follow-up processing

[0057] The water-soluble gauze prepared in step (1) is subjected to acupuncture treatment; the first step is the pre-needl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com