A chain automatic welding device and welding process

A technology of automatic welding and process flow, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve problems affecting production efficiency, increasing labor costs, and a large number of labor, so as to save labor, speed up production, and realize flexible production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

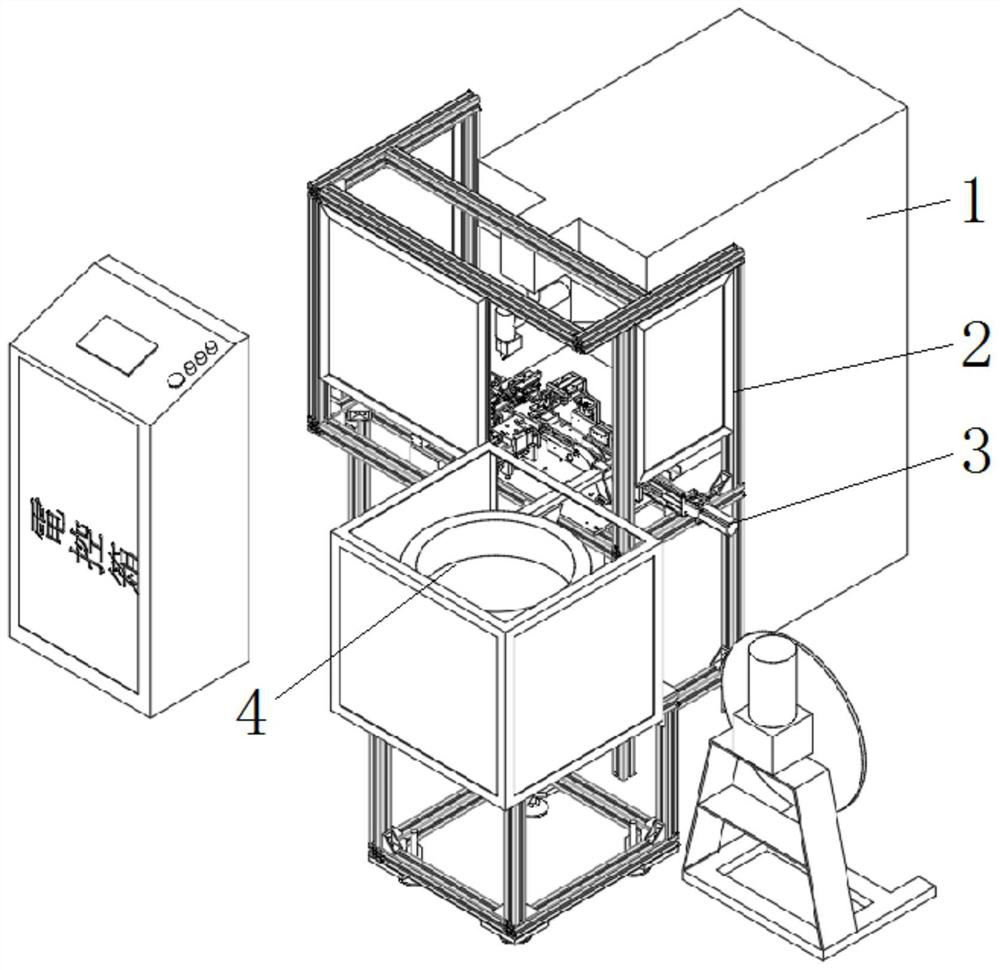

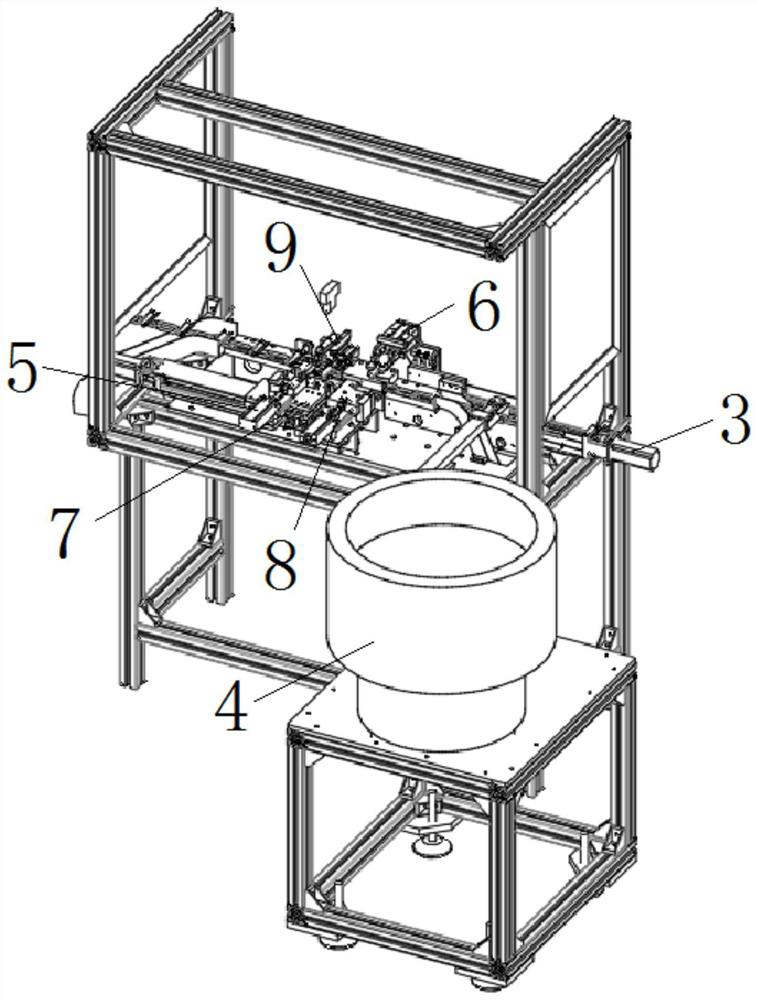

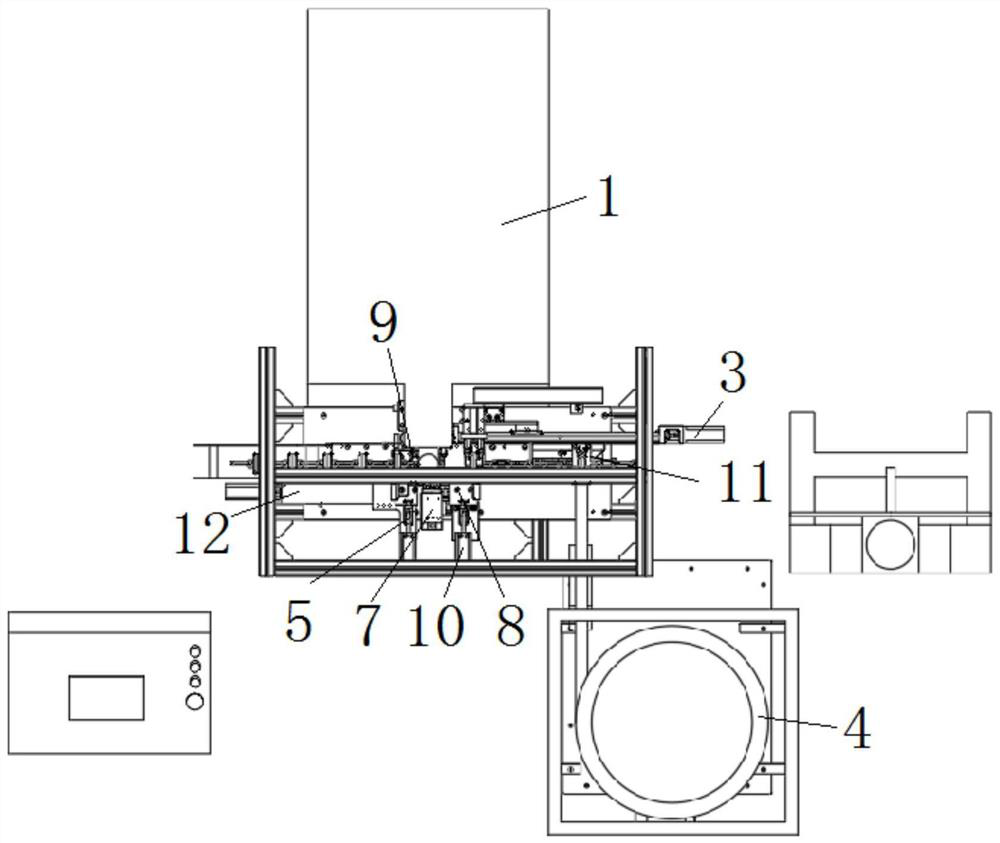

[0035] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0036] refer to Figure 1-4 , a chain automatic welding device, comprising a welding machine 1, a support frame 2 is installed on the front of the welding machine 1, an L block feeding module 3 is installed in the support frame 2, and an L block feeding module 3 is located in the support frame 2 and welded An L-shaped block clamping module 6 is installed between the machine 1, an L-block positioning unit 9 is installed near the L-shaped block clamping module 6 in the support frame 2, and an L-block positioning module 9 is installed in the support frame 2 outside the L-block feeding module 3 There are chain feeding module 5, L block positioning one 7 and chain positioning module 8, and the chain feeding module 5, L block positioning one 7 and chain positioning module 8 are distributed from left to right, and a drive is installed in the support frame 2 Motor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com