Assembly line for production of steel-structure protection doors

A technology for assembly lines and protective doors, which is used in assembly machines, hoisting devices, transportation and packaging, etc. It can solve the problems of low assembly efficiency, cluttered various accessories, and long assembly time, so as to facilitate rapid assembly and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

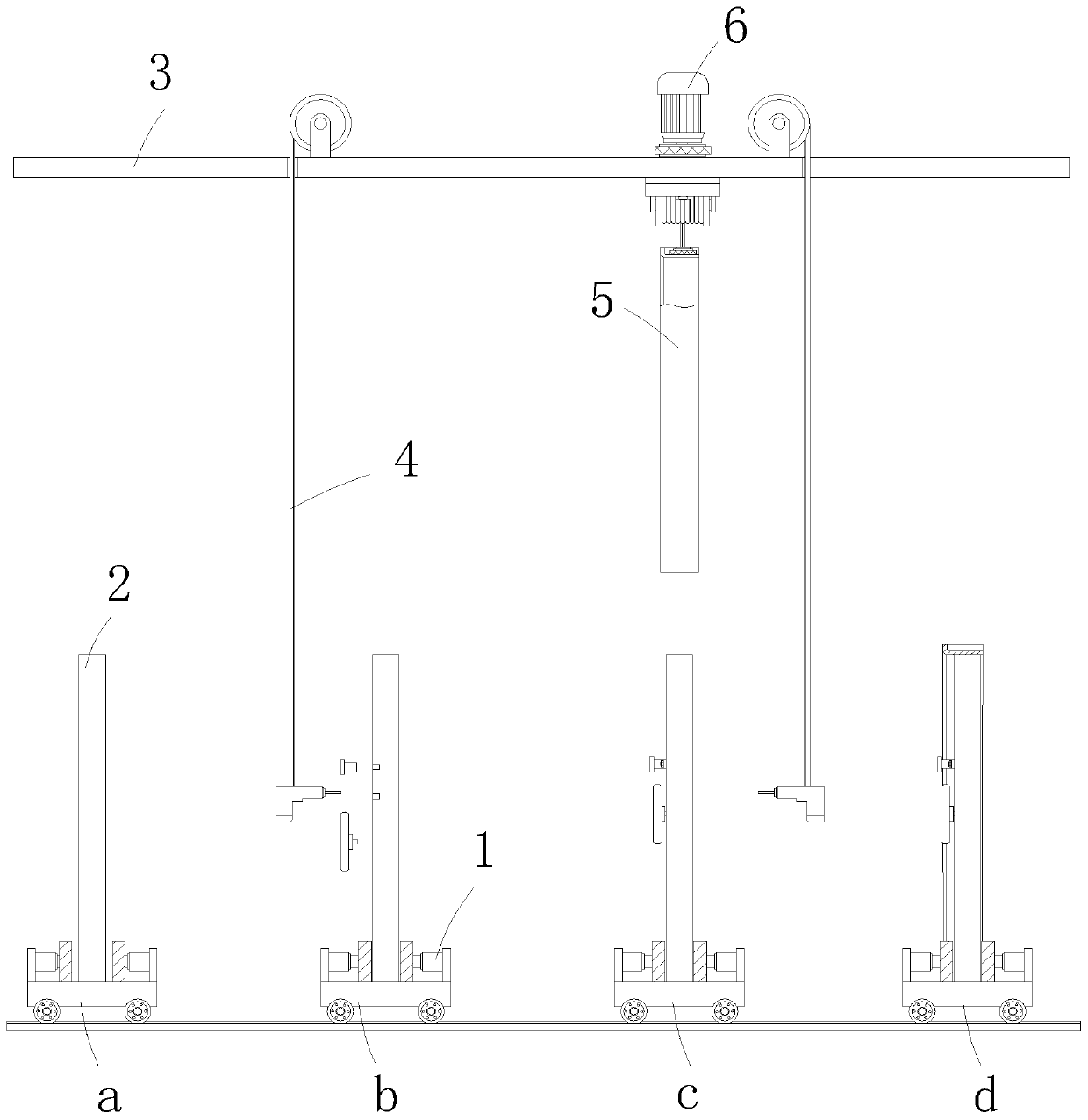

[0036] Attached below Figure 1-9 The present invention is further described with embodiment:

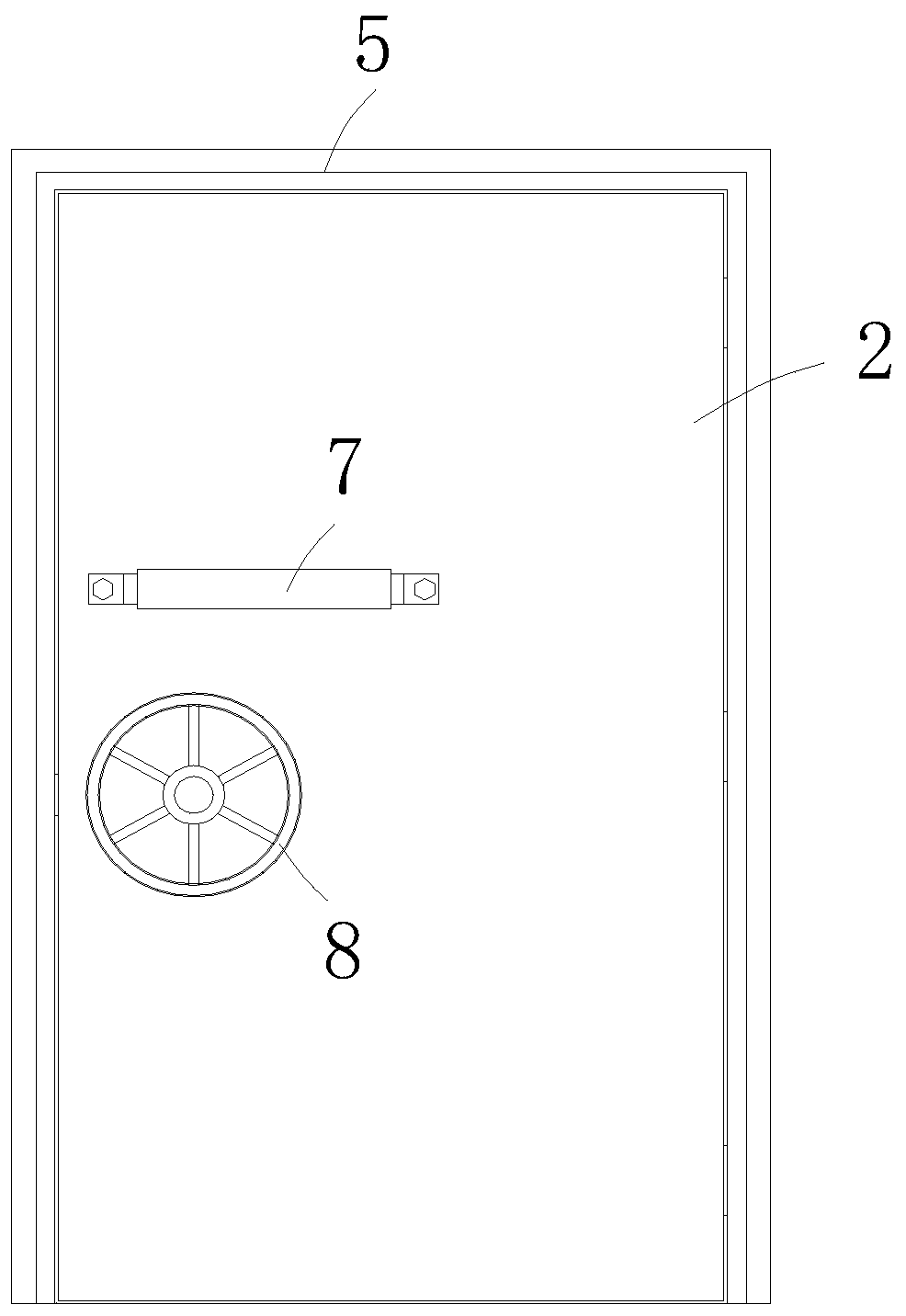

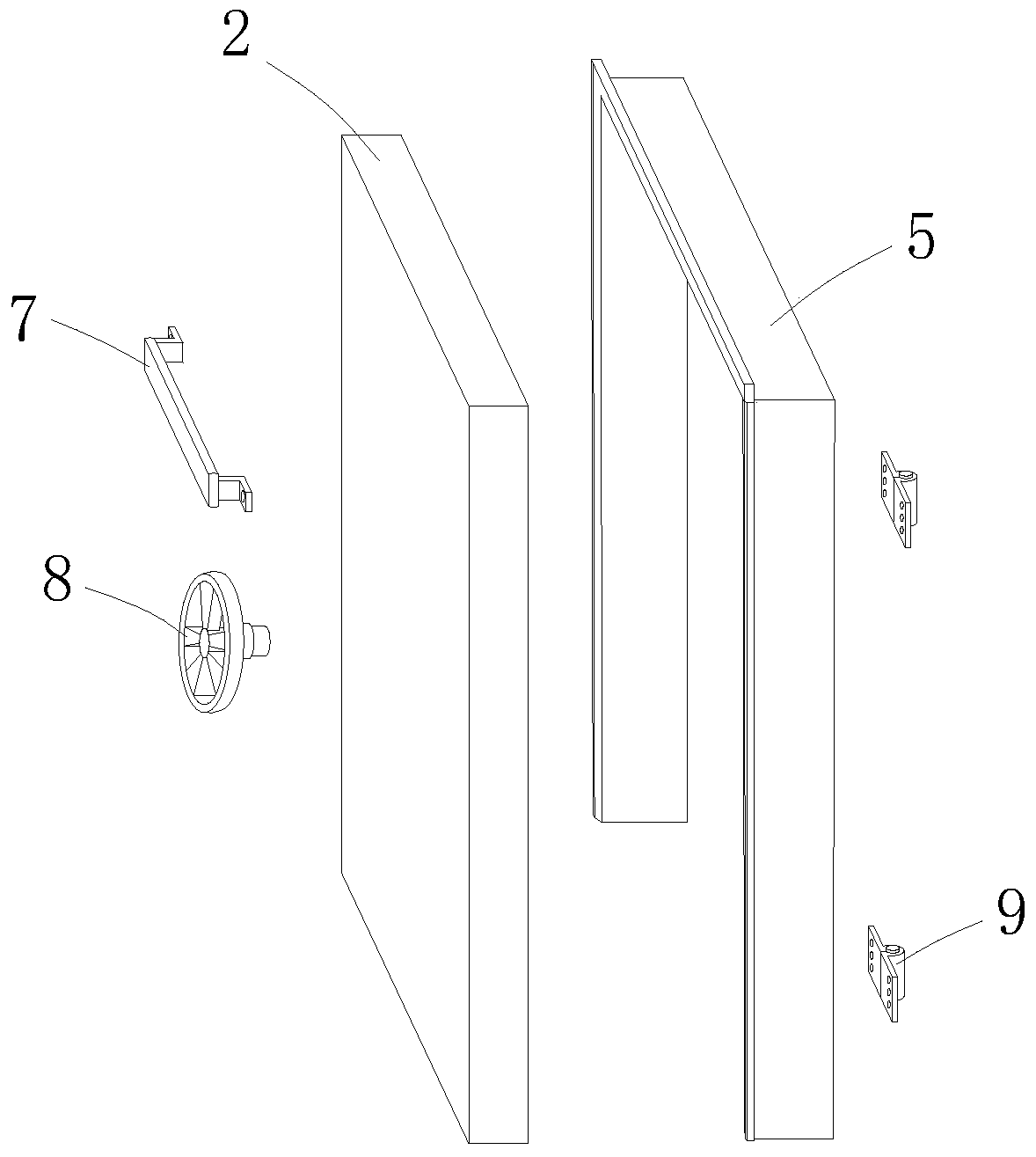

[0037] An assembly line for the production of steel protective doors, including a transfer trolley 1 as a circulation unit and a door leaf 2 vertically fixed on the transfer trolley 1, and the door leaf 2 passes through the first station a and the second station on the assembly line in sequence b. The third station c and the fourth station d are transferred and processed to form a fast assembly line for steel protective doors, in which the first station a, the second station b, the third station c, and the fourth station A workshop beam 3 extending along the flow direction of the door leaf 2 is provided above the station d to ensure the installation of various assembly equipment and facilitate quick assembly. The positions of the workshop beam 3 corresponding to the second station b and the third station c are equal An assembly mechanism 4 is provided to ensure access to various el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com