A Detection Method of Liquid Iron Flow Velocity Based on Polarization Characteristics

A technology for flow velocity detection and polarization characteristics, which can be used in inspection devices, image enhancement, furnaces, etc., and can solve the problem of low flow velocity detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

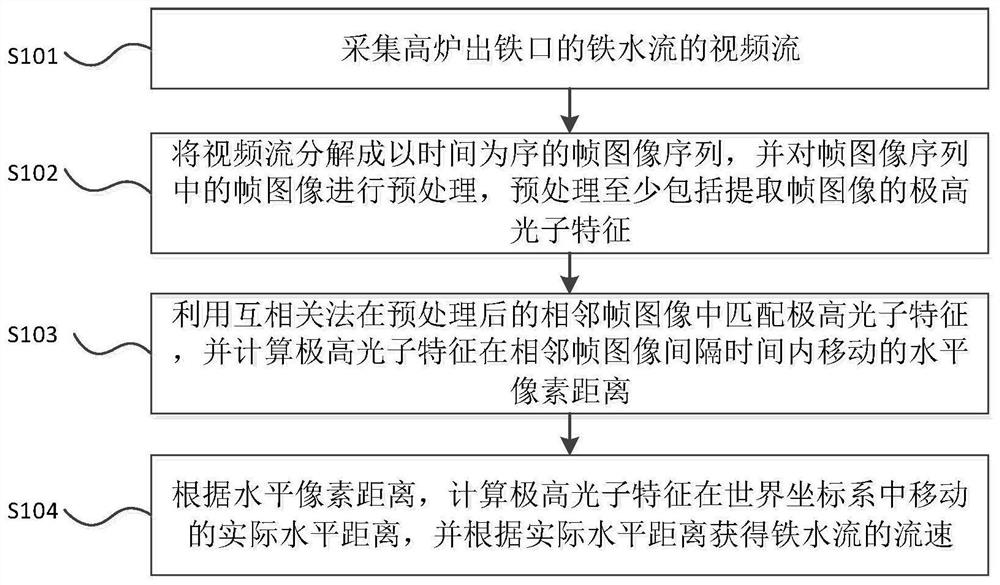

[0069] refer to figure 1 The method for detecting the flow rate of molten iron based on polarization characteristics provided in Embodiment 1 of the present invention includes:

[0070] Step S101, collecting the video stream of the molten iron flow in the blast furnace taphole;

[0071] Step S102, decomposing the video stream into time-ordered frame image sequences, and performing preprocessing on the frame images in the frame image sequence, the preprocessing at least includes extracting extremely high photon features of the frame images;

[0072] Step S103, using the cross-correlation method to match the extremely high photon features in the preprocessed adjacent frame images, and calculating the horizontal pixel distance that the extremely high photon features move during the interval between adjacent frame images;

[0073] Step S104 , according to the horizontal pixel distance, calculate the actual horizontal distance that the extremely high photon feature moves in the wo...

Embodiment 2

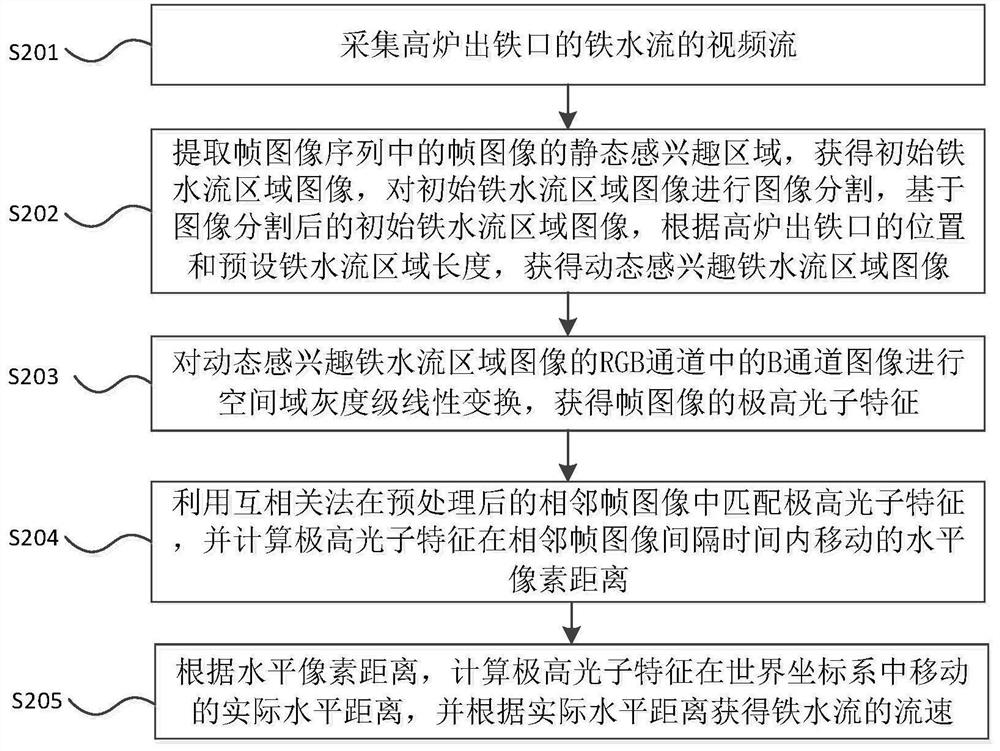

[0080] refer to figure 2 , the method for detecting the flow rate of molten iron based on polarization characteristics provided by Embodiment 2 of the present invention includes:

[0081] Step S201, collecting a video stream of molten iron flow in a blast furnace taphole.

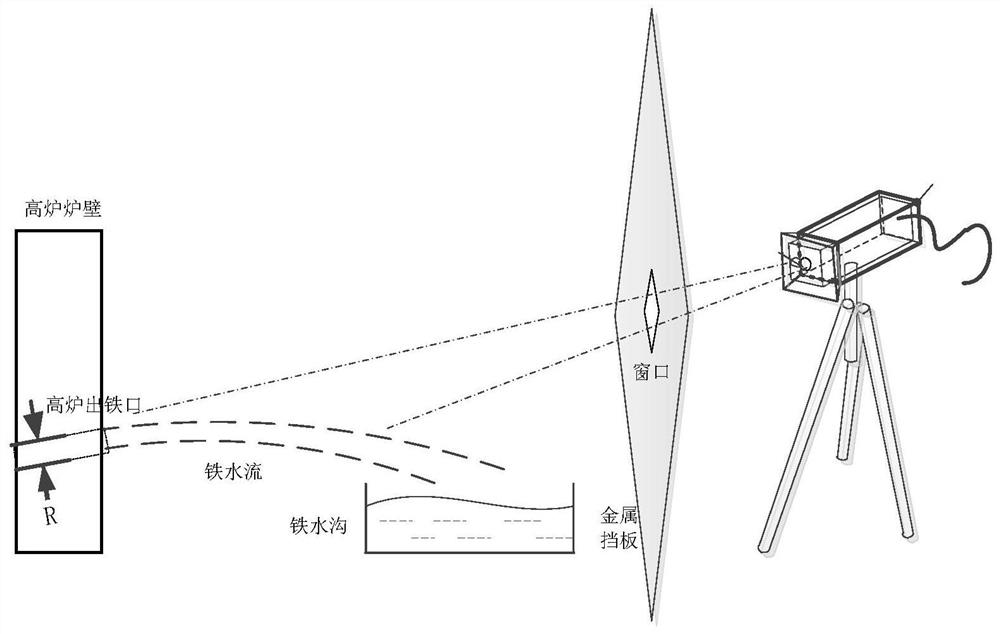

[0082] Specifically, this embodiment first determines the type selection of the high-speed camera, and installs the protective device, selects a suitable location at the blast furnace taphole site to install and fix the camera, refer to image 3 , collect high frame rate iron flow video, and perform camera calibration. In terms of camera selection, in order to meet the needs of speed measurement, the most important thing is the parameter selection of frame rate and resolution. A suitable frame rate can obtain the details of molten iron flow, and sufficient resolution can provide more detailed information on the image, and the camera It has the functions of light reduction filter and anti-dust and anti-no...

Embodiment 3

[0126] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings. The present invention is applied to a 2650m 3 On the blast furnace, the three tapholes on the blast furnace are in accordance with image 3 Install high-speed cameras and protective devices. According to the estimation of on-site workers, the flow rate of molten iron at the blast furnace taphole is 5-6m / s. In order to meet the needs of flow rate detection, the high-speed camera has a resolution of 1280*720 and a frame rate of 240. In order to make the high-speed camera run stably, the protection device uses air cooling to isolate a large amount of external heat radiation and take away the heat emitted by the high-speed camera. The specific implementation is based on Figure 6 The schematic diagram to complete the entire detection process of molten iron flow rate, the detection steps are as follows:

[0127] According to the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com