Double-layer ceramic insulating non-toxic irradiation-free electric wire and manufacturing method thereof

A radiation-free, ceramic technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of lengthy and complicated production process, lack of long-term high temperature resistance, and great influence of human factors, etc., to achieve strong tensile resistance Improvement of performance and fire performance, and improvement of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

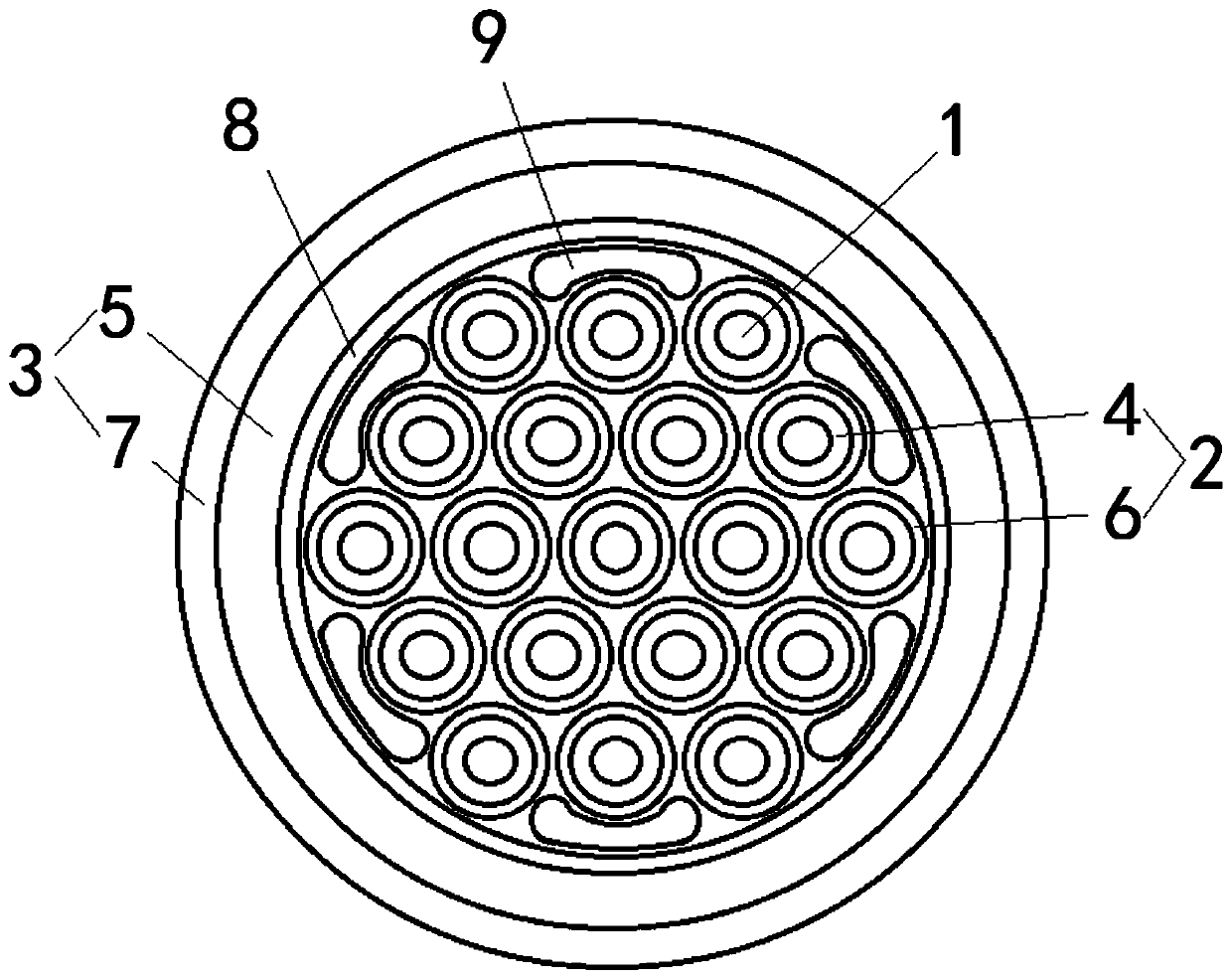

[0026] according to figure 1 , figure 2 , a double-layer ceramic insulated non-toxic radiation-free wire, including one or more metal cores 1, each of the metal cores 1 is uniformly wrapped with an inner skin 2, and also includes a wire for wrapping all the inner skins 2 and the outer skin 3 of the metal core 1, wherein: the inner skin 2 is composed of a first ceramic layer 4 coated on the outside of the metal core 1, and a first insulation layer coated on the outside of the first ceramic layer 4 The radiation layer 6 is formed; the outer skin 3 is composed of a second ceramic layer 5 and a second radiation-free layer 7 sequentially provided from the inside to the outside.

[0027] The first radiation-free layer 6 is made of the following materials by weight: 40-80 parts of polypropylene resin, 12-15 parts of modified hydrotalcite, 8-16 parts of heat stabilizer, and 40-60 parts of plasticizer , 4-8 parts of modified auxiliary agent, 2-4 parts of flame retardant, 0.5-1 part ...

Embodiment 2

[0030] The first ceramic layer 4 is composed of ceramic fiber filaments tightly wound outside the metal core 1 to form a thickness; the second ceramic layer 5 is composed of ceramic fiber tapes spirally wound outside the inner skin 2 .

[0031] In the above arrangement, the helically wound ceramic fiber tape not only ensures the wire-making efficiency of the sheath 3, but also increases the degree of saturation of the second ceramic layer 5, thus improving the fireproof performance.

Embodiment 3

[0033] The inner skin 2 is nested with a metal shielding net 8 between the inner walls of the second ceramic layer 5; inside the metal shielding net 8, a plurality of tension bands 9 are arranged along the length direction.

[0034] In the above configuration, the metal shielding net 8 improves the anti-interference ability of the cable, and at the same time, the metal shielding net 8 and the tensile tape 9 provide the cable with strong tensile resistance and avoid breakage due to external force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com