Redox flow battery

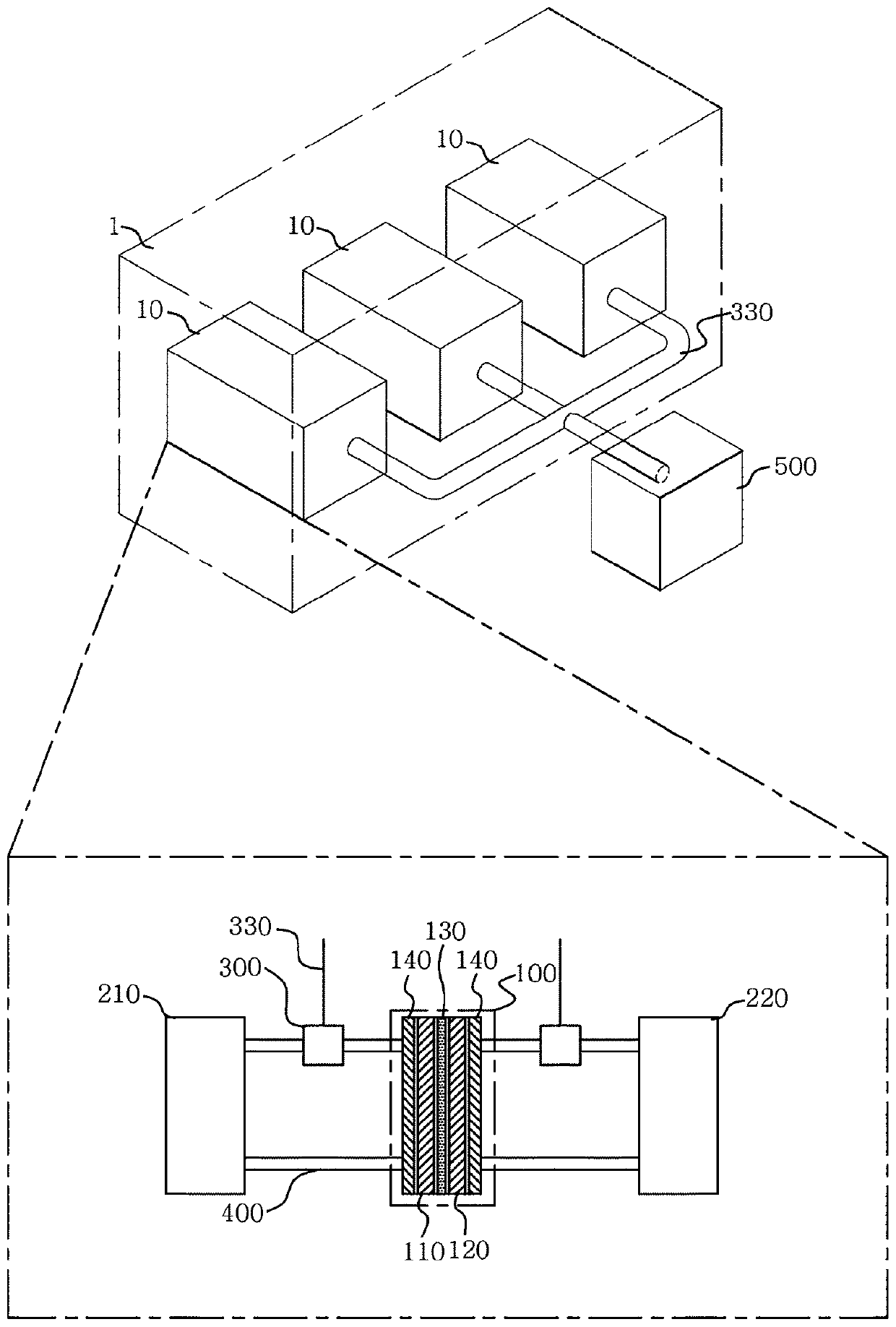

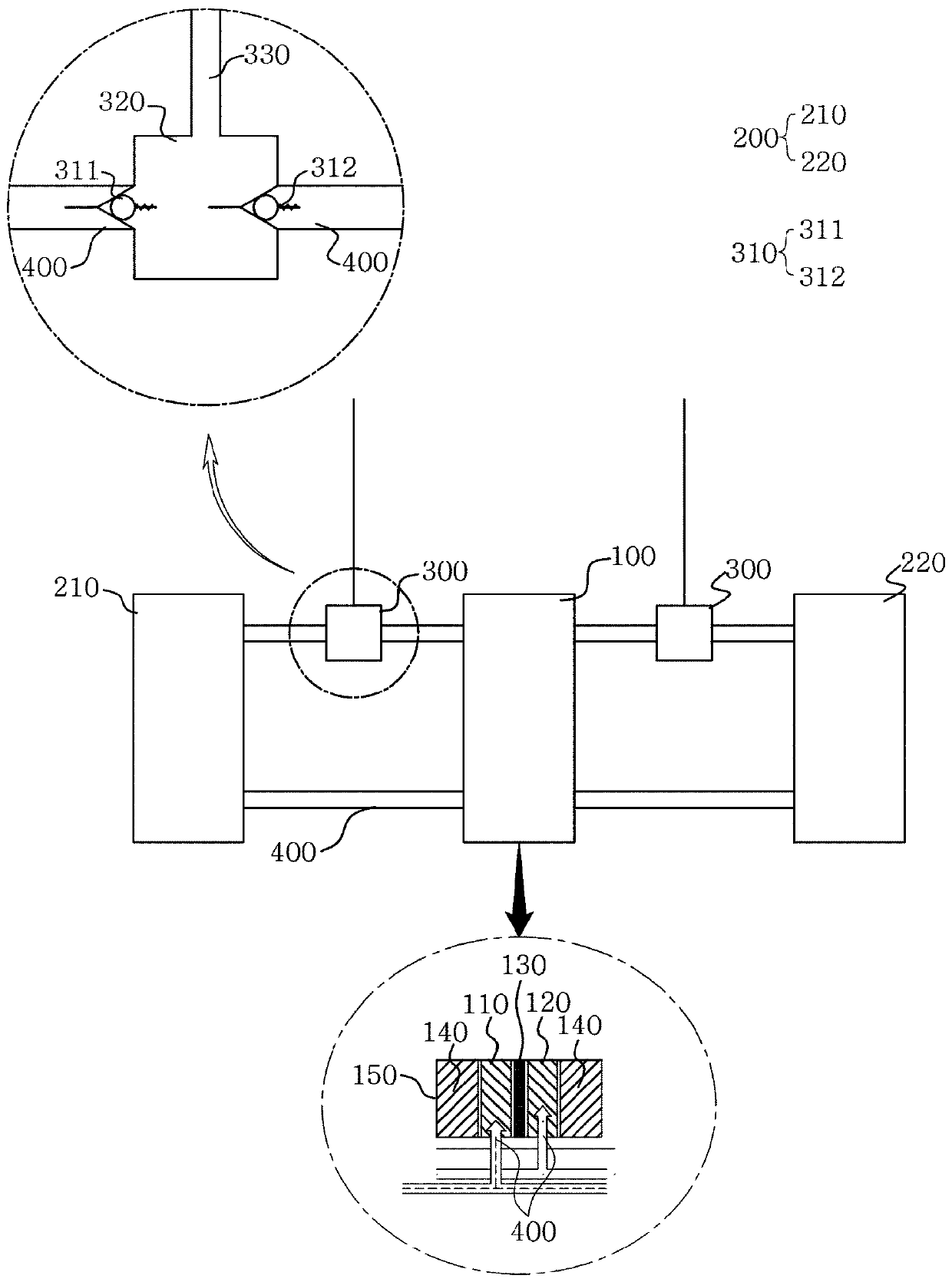

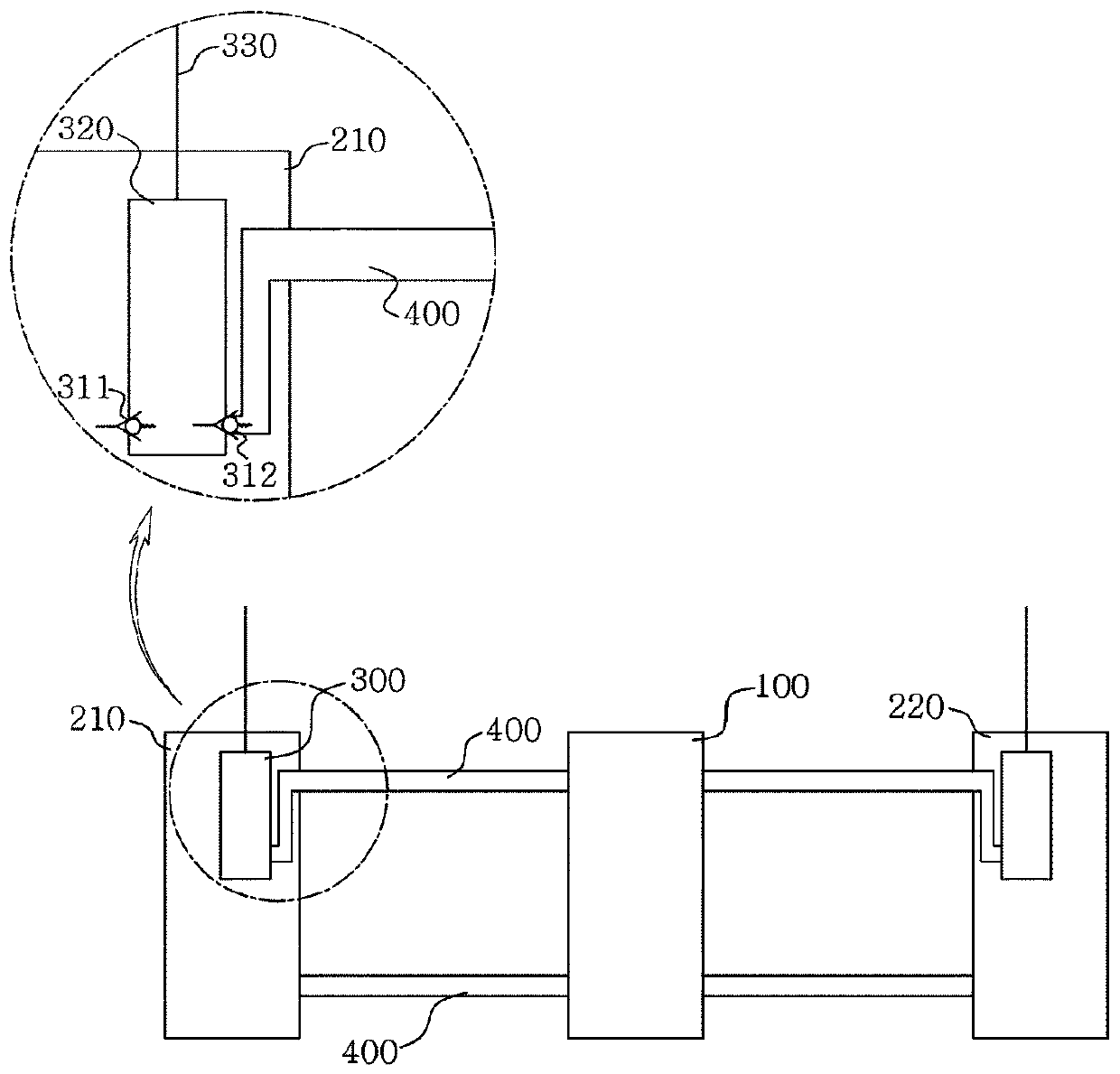

A flow battery and battery cell technology, applied in fuel cells, regenerative fuel cells, fuel cell grouping, etc., can solve problems such as increased fluid flow resistance pumping loss, uneven performance of battery cells, and decreased efficiency, and achieves a reduction in or The effect of shunt current, power saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] (Example 1, Comparative Examples 1 to 2)

[0183] There are 10 fluid control parts in total, and they are connected to one pressure generator, and two fluid control parts are respectively connected to one electrolyte tank. Then, the flow rate of the electrolytic solution transferred through each fluid control unit was measured one by one. At this time, when the maximum volume V of the electrolyte is h and the reaction volume of the electrolyte V c The ratios of the ratios were adjusted to 0.05 (embodiment 1), 0.02 (comparative example 1), and 20 (comparative example 2) to measure flow deviation ratios and record them in Figure 14 and Table 1.

[0184] [Table 1]

[0185] V h / V c

Flow Deviation Ratio Example 1 0.05 0.05 Comparative example 1 0.02 1.0 Comparative example 2 20 0.05

[0186] When the flow rate deviation ratio is 1, it means that at least one fluid control unit among the plurality of fluid control units cannot...

Embodiment 2

[0190] In order to measure the critical flow rate, the conditions are set to be the same as in Example 1, and since the average flow rate per minute is V c Experiments were carried out in the range of 3000% from 0.5% of the battery cell, and the change in efficiency of the battery cell was measured. In this range, the efficiency deviation ratio calculated according to Equation 4 is shown in a graph. At this time, since the average flow per minute is V c Values ranging from 0.5% to 10% are shown graphically because there is no significant difference in the resulting values above 10%.

[0191] As shown in (c) of Figure 14, it was confirmed that the critical flow rate is V when the electrolyte solution flows per minute. c When more than 3% of the battery cell efficiency deviation is greatly reduced. Therefore, the preferred critical flow rate is V c 3% or more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com