Composite venturi type micro-bubble generating device

A bubble generating device and composite venturi technology, applied in the field of micro-bubble, can solve the problems of inability to reach micron level, low efficiency, high energy consumption, and achieve the effects of convenient and safe operation and maintenance, not easy to malfunction, and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

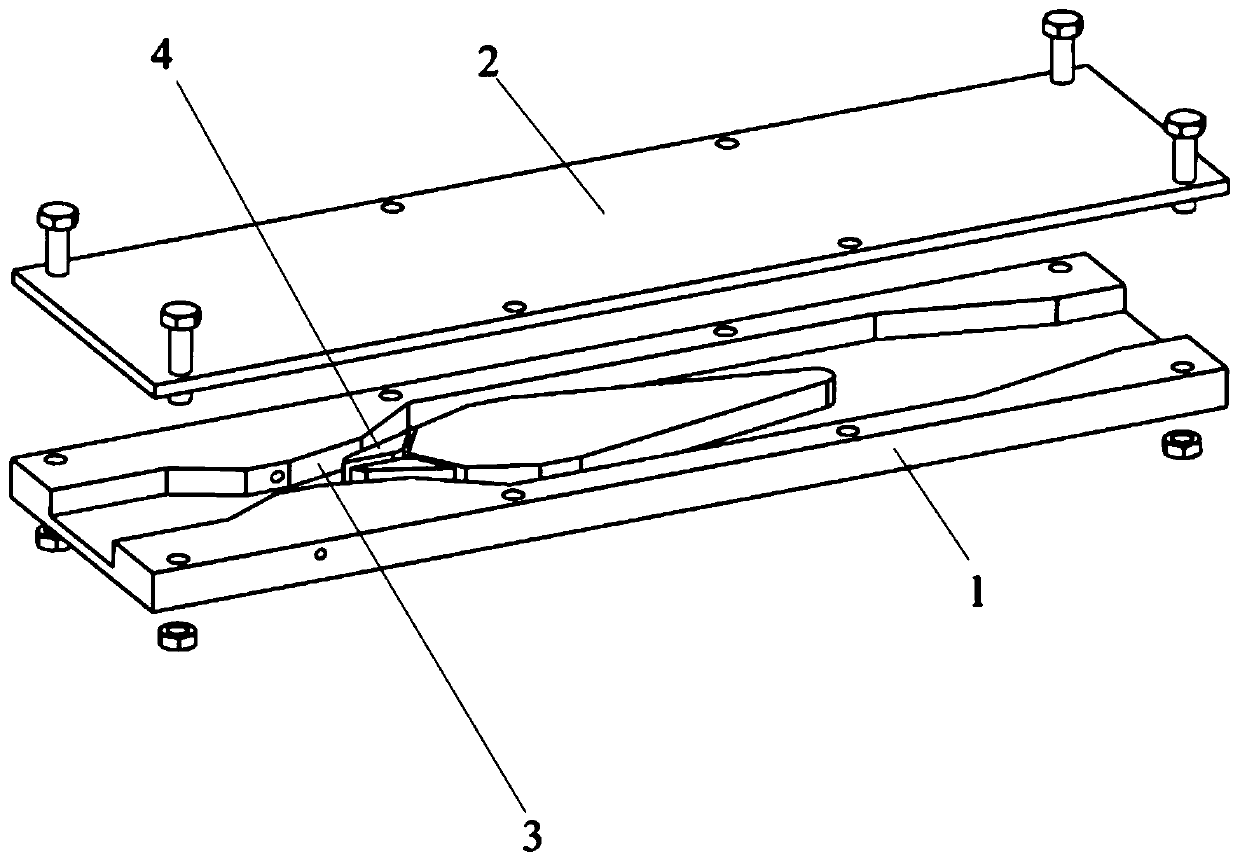

preparation example Construction

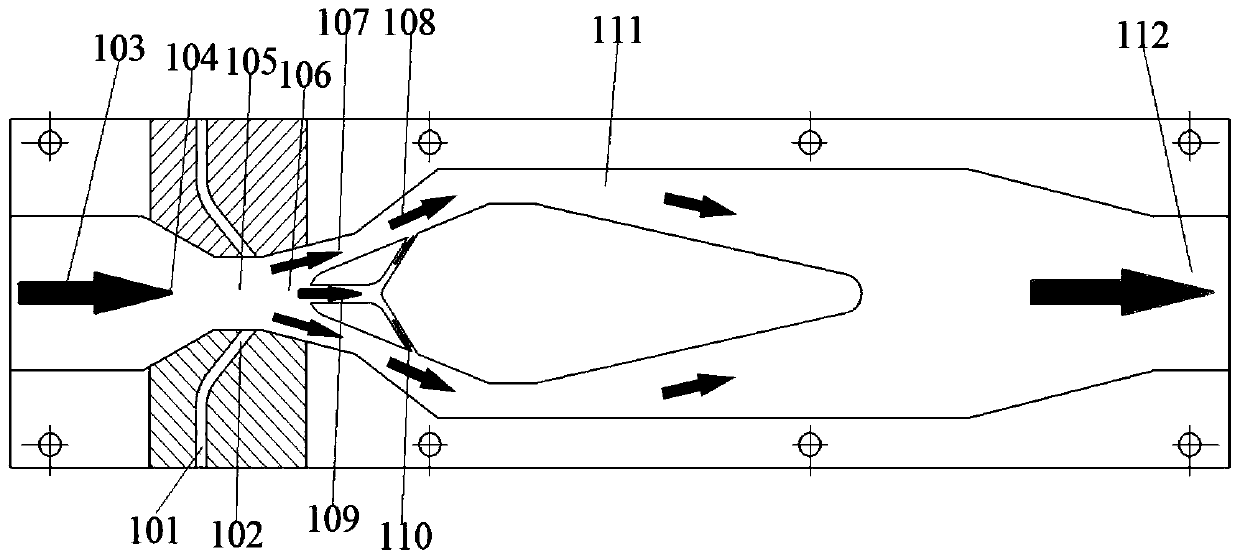

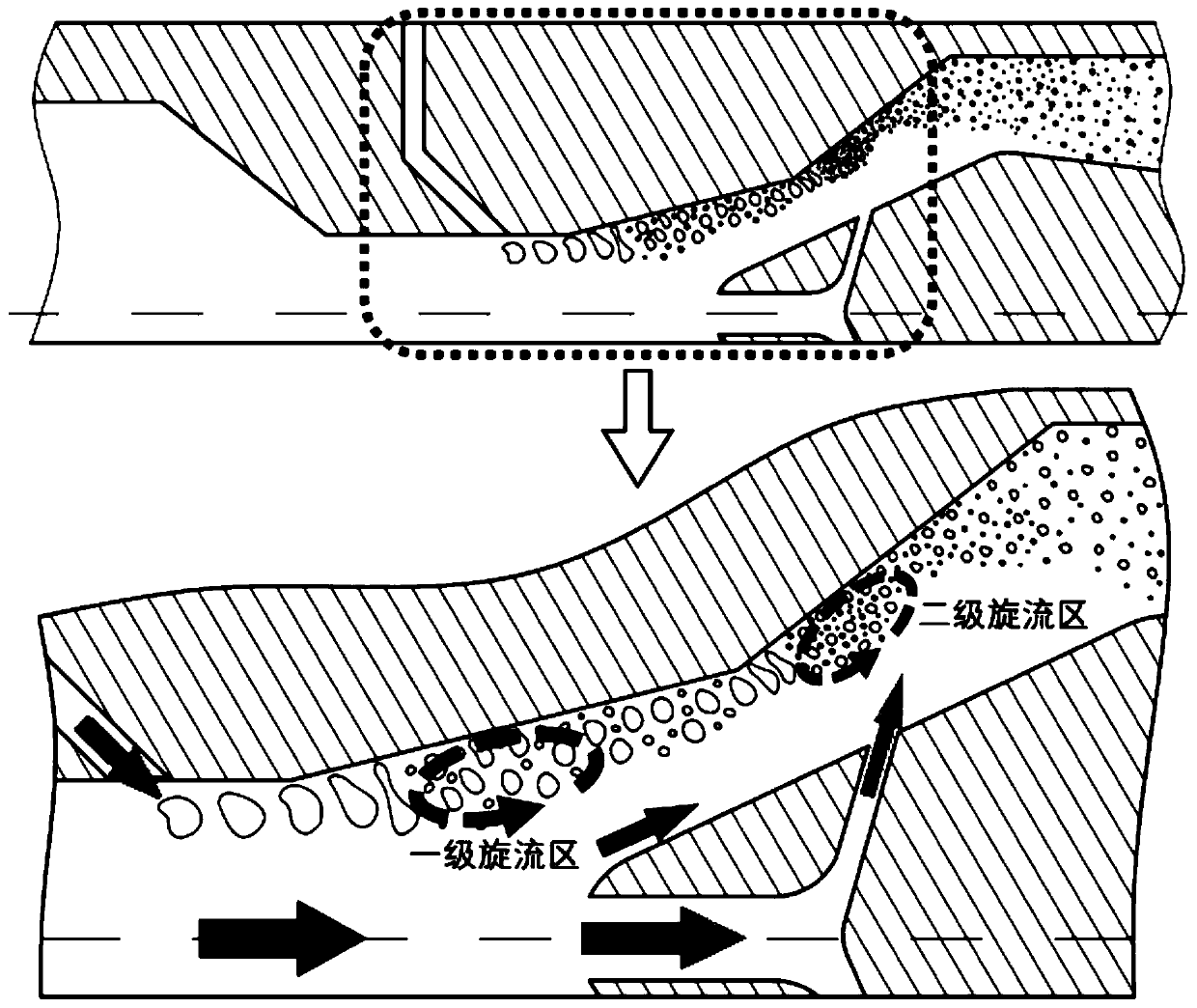

[0030] In the past two decades, the technology of using microbubbles to enhance heat and mass transfer processes has made great progress in the fields of biology, chemistry and the environment, and even applied microbubbles to ship navigation drag reduction. The preparation method of microbubbles has also made great progress. Typical microbubble generators mainly include: (1) liquid rotary type; (2) Venturi type; (3) ejector type; (4) flash type. Among them, the Venturi bubble generator has the simplest structure, easy processing and production, the highest safety and economy, and the most widely used.

[0031] The cross-section of the traditional Venturi bubble generator is mostly circular, and there are multiple air inlets equidistantly arranged in the throat. The device uses the negative pressure of the throat to inhale gas from the inlet, and then uses the turbulent flow of the Venturi expansion section to tear the gas to produce tiny bubbles. However, the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com