Intelligent paper cutter for motor insulating paper

A technology of insulating paper and paper cutting machine, applied in metal processing and other directions, can solve the problems of uneven cutting part of insulating paper, fixed cutting part of insulating paper, easy sliding of insulating paper, etc. the effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

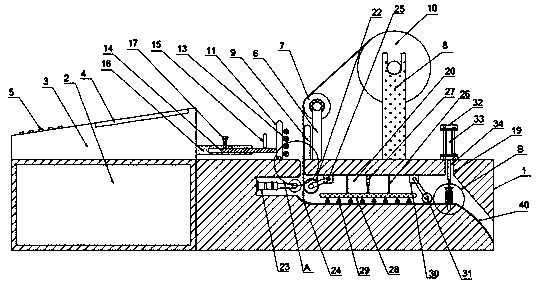

[0029] Such as Figure 1-5 A cutting machine for intelligent motor insulating paper is shown, which includes a body 1, a power supply box 2 is provided on one side of the body 1, a control box 3 is provided on the top of the power supply box 2, and a control box 3 is installed inside the control box 3. There is a single-chip microcomputer 4, and the top of the control box 3 is provided with a control button 5;

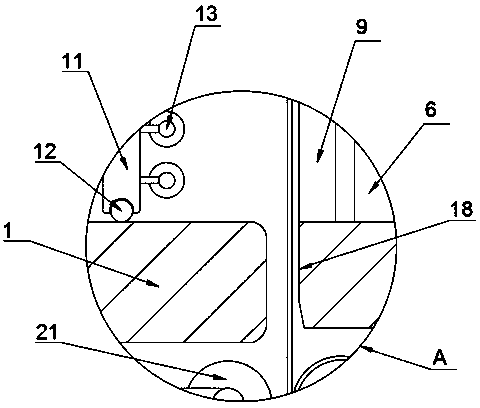

[0030] The top of the body 1 is provided with a support rod 6, the top of the support rod 6 is provided with an adjustment roller 7, one side of the support rod 6 is provided with a frame bar 8 and the other side is provided with a feed baffle 9, and the frame The top of the rod 8 is provided with a raw material roller 10, one side of the feed baffle 9 is provided with a feed pressing plate 11, the bottom of the feeding pressing plate 11 is embedded with a ball 12, and the side wall of the feeding pressing plate 11 is provided with a pressing plate. The material rolle...

Embodiment 2

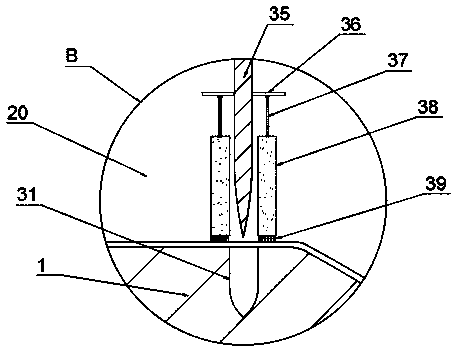

[0034] Such as Figure 1-5 Shown is a paper cutter for intelligent motor insulating paper, the input ends of the first electric push rod 23, the second electric push rod 27, the first drive motor 25, the second drive motor 30 and the cutting cylinder 33 are all A relay is provided, and the relay is used to transmit on-off commands to control the change of the working state of the above-mentioned electrical components. The input end of the relay is connected to the output end of the single-chip microcomputer 4, and the single-chip microcomputer 4 is set as an ARM type 8-bit single-chip microcomputer 4 ;

[0035] Further, the adjusting tube 16 is fixedly arranged on the side wall of the control box 3, the end of the adjusting rod 14 is inserted into the inside of the adjusting tube 16, the adjusting rod 14 is flexibly connected with the adjusting tube 16, and the adjusting The bottom end of the screw 17 passes through the adjustment tube 16 and the bottom end is attached to the...

Embodiment 3

[0042] Such as figure 1 As shown, when working, place the raw material roll 10 wrapped with motor insulation paper on the frame rod 8, pull the insulation paper by hand, and a support rod 6 is provided on one side of the frame rod 8, and the top of the support rod 6 is provided with an adjustment Roller 7 pulls the insulating paper on the raw material roller 10 and covers the insulating paper on the adjusting roller 7;

[0043] Such as Figure 1-2 As shown, pull the insulating paper and place the bottom end of the insulating paper inside the feed hole 18, continue to pull the insulating paper so that the bottom of the insulating paper is placed between the moving pressure roller 21 and the first transmission roller 22, turn the adjusting screw 17, and cancel the adjustment The screw 17 has a limiting effect on the adjustment rod 14 in the adjustment tube 16, pushes the pull rod 15 on the adjustment rod 14, and drives the feed pressure plate 11 to move to the feed baffle 9 sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com