Imaging method and device for realizing automatic track board crack detection

An automatic detection and imaging method technology, which is applied in image analysis, transportation and packaging, image data processing, etc., can solve problems such as low efficiency, failure to meet the needs of track safety early warning, and high cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

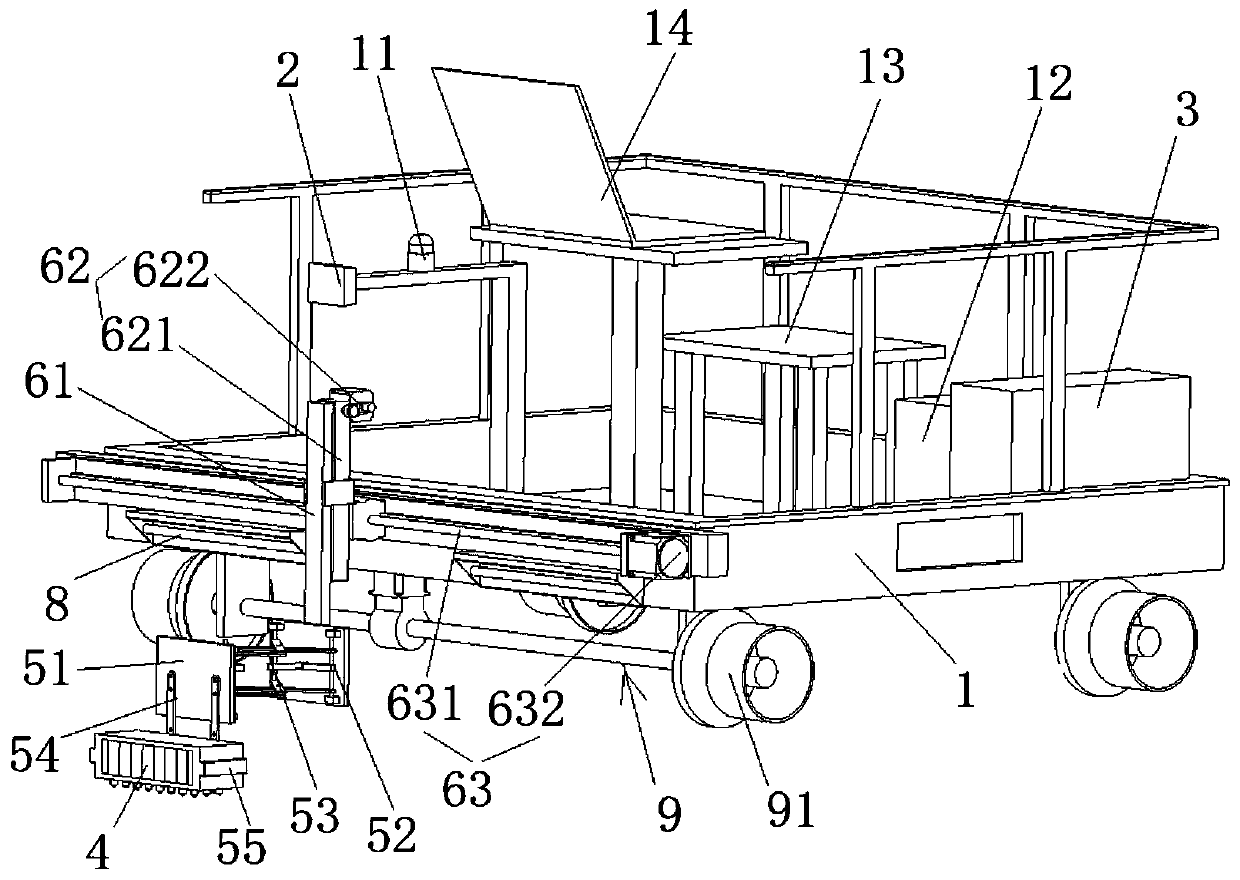

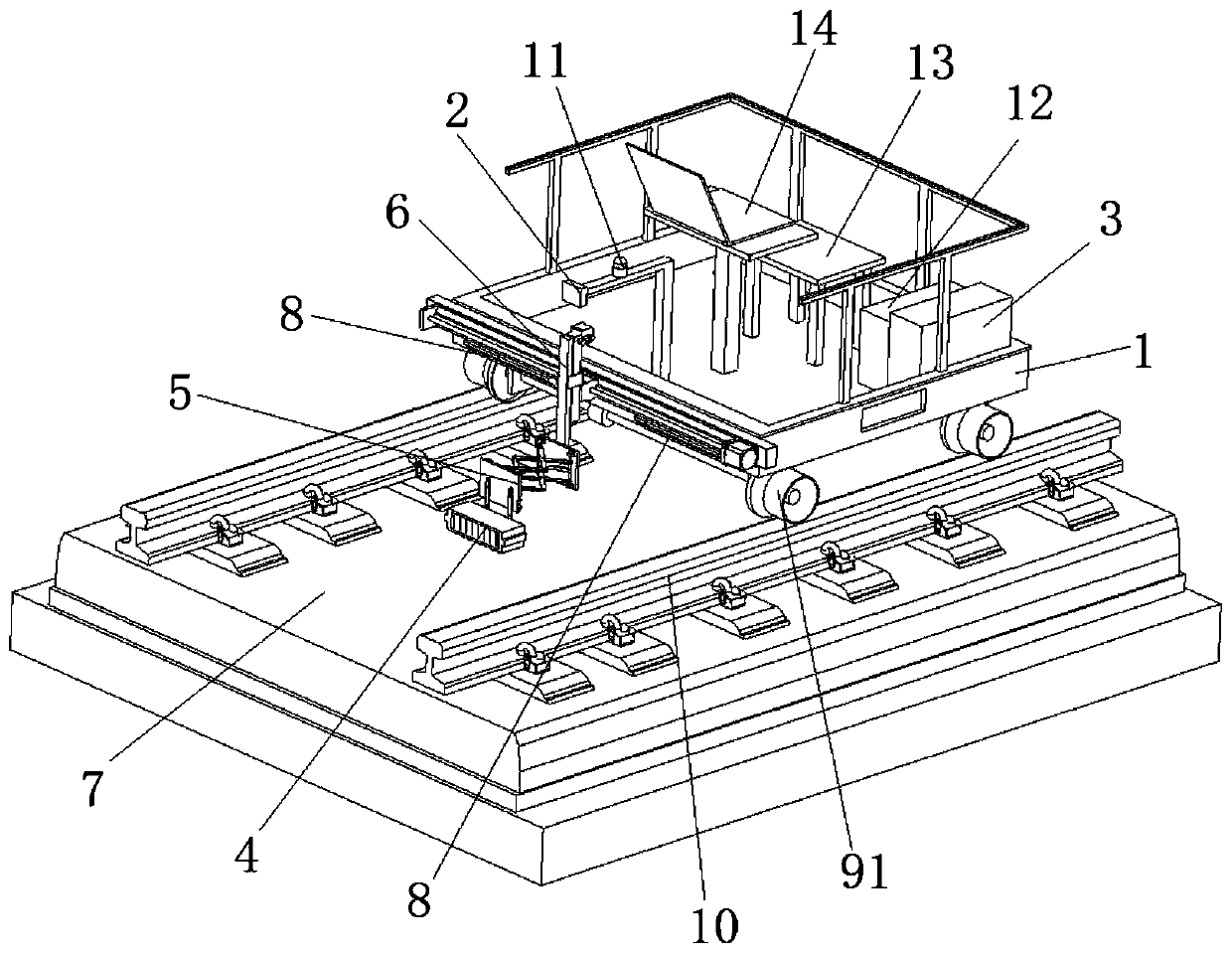

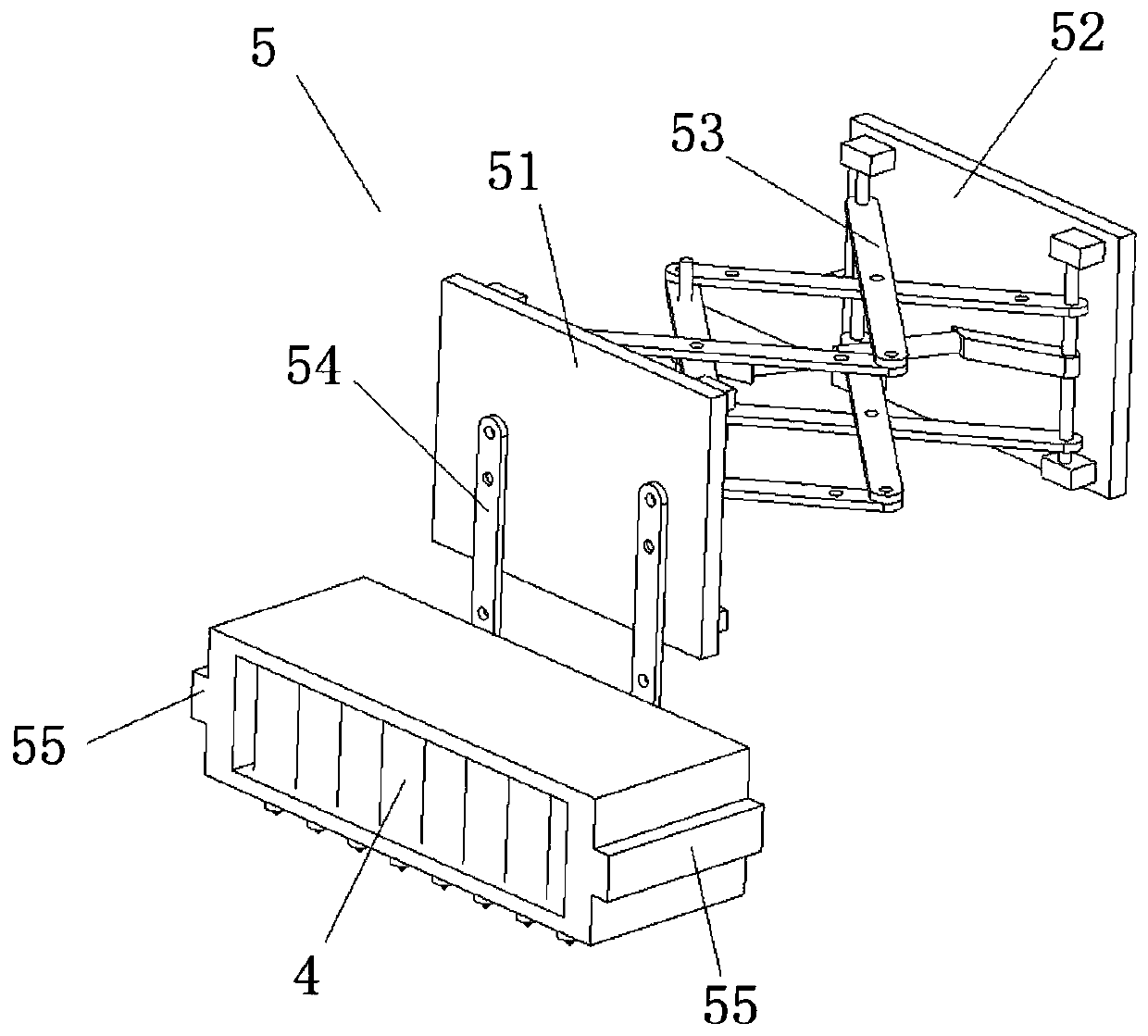

[0067] combine Figure 1 to Figure 3Shown: a kind of imaging device that realizes the automatic detection of rail slab crack provided by the present invention, comprises track inspection trolley 1 and camera 2 and computer 14 that are arranged on track inspection trolley 1, and described camera 2 is connected with computer 14 signal , also includes an ultrasonic transmitting receiver 3 and an ultrasonic linear array probe 4, the transmitting end of the ultrasonic linear array probe 4 is connected to the transmitting interface signal of the ultrasonic transmitting receiver 3, the receiving end of the ultrasonic linear array probe 4 is connected to the ultrasonic transmitting The receiving interface signal of receiver 3 is connected, and the receiving interface of described ultrasonic transmitting receiver 3 is connected with computer 14 signal, and described ultrasonic linear array probe 4 is connected with an adaptive telescopic mechanism 5, and described self-adaptive telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com