Unmanned grab bucket positioning method of combination storage material managing system

A technology of combined storage and positioning method, which is applied in the field of unmanned crane grab positioning, can solve the problems of low manual operation efficiency, slow material loading speed, high work intensity, etc., and achieve precise control and a high degree of integrated automation, The effect of improving the degree of automation and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the protection scope of the present invention cannot be limited by this. The purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

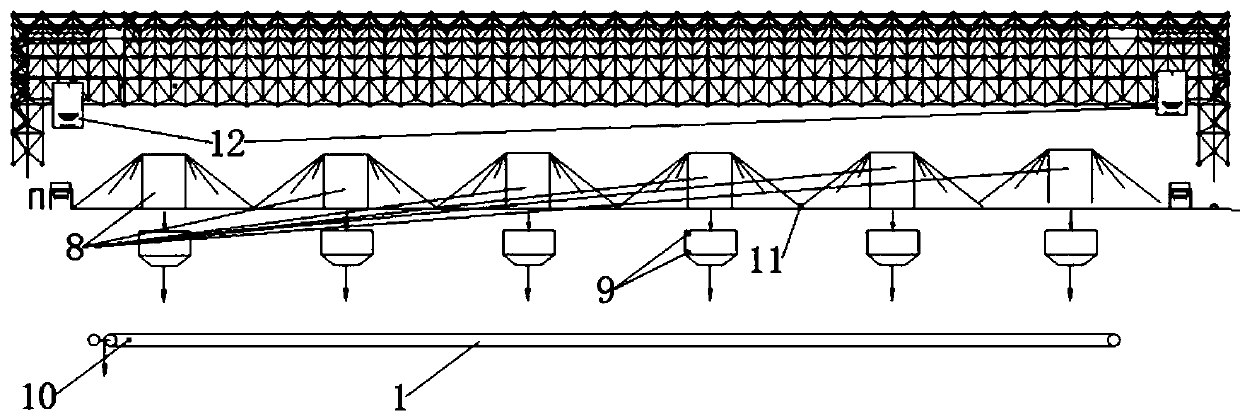

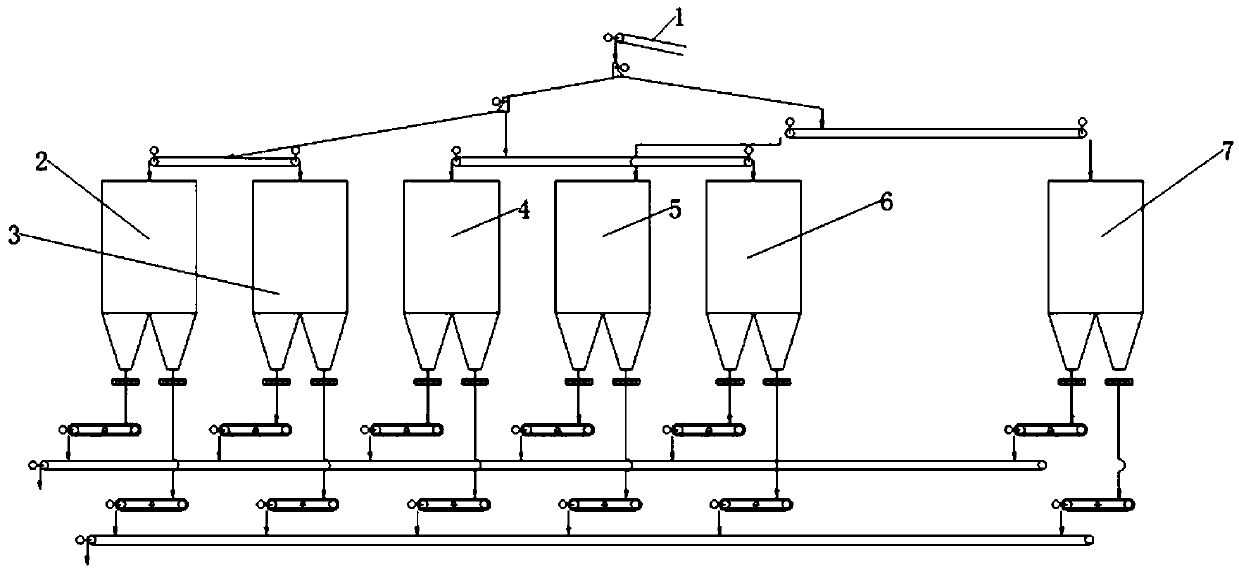

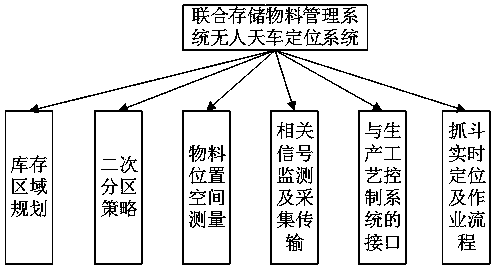

[0040] combined with Figure 1-4 A method for locating the grab bucket of an unmanned overhead crane in a combined storage material management system includes the following steps:

[0041] 1. Inventory area planning for incoming materials in the joint inventory system;

[0042] The inventory area planning of the joint storage system is planned according to six kinds of materials. According to the ratio, the area of the storage area is 90 meters * 40 meters, and it is planned to be 6 rectangular partitions, which are respectively 1#-6# material storage area 8; one kind of material, one partition , the large ratio material partition is located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com