A method for leaching zinc from high-cobalt slag of hydrometallurgy

A technology for hydrometallurgical zinc and high cobalt, applied in the field of zinc leaching, can solve the problems of long process flow, high cost, difficulty in leaching zinc, etc., and achieve the effect of realizing recycling, low cost and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

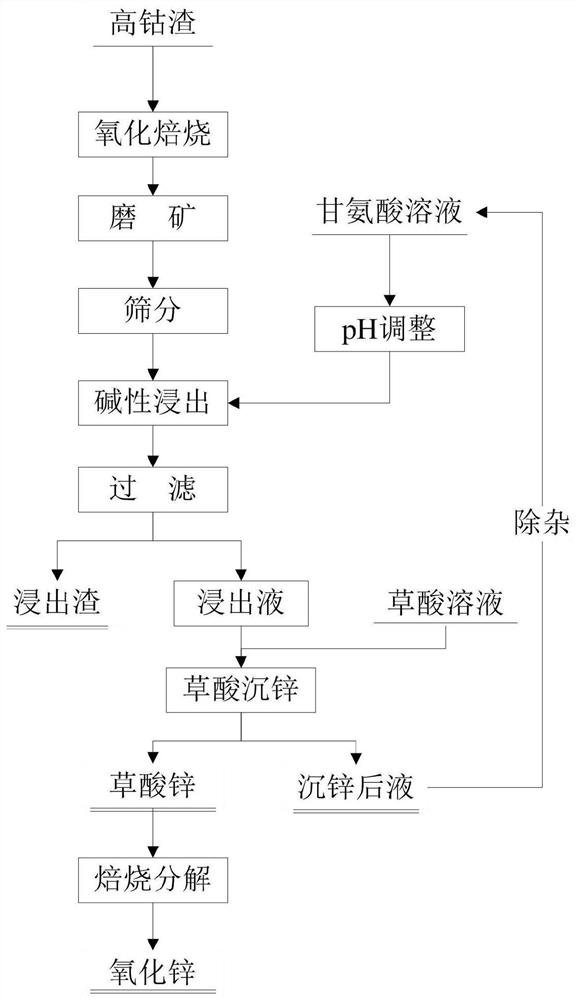

Method used

Image

Examples

Embodiment 1

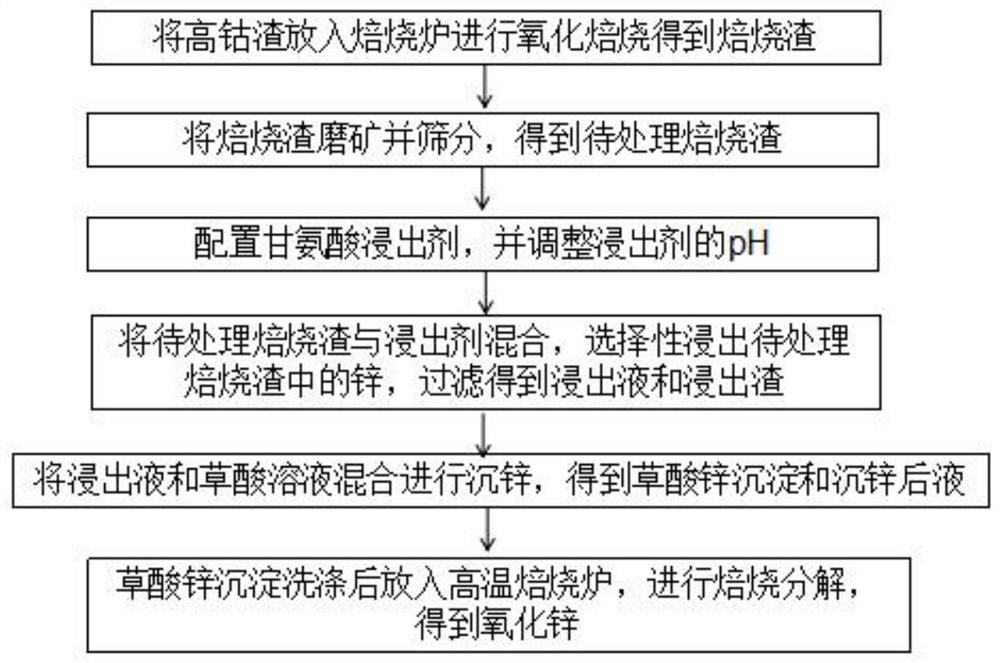

[0071] This embodiment provides a method for leaching zinc from the high-cobalt slag of hydrometallurgy, comprising the following steps:

[0072] (1) Oxidation roasting: put the high-cobalt slag into a high-temperature roasting furnace, and roast at 400°C for 30 minutes, so that the zinc and cobalt occurrences in the high-cobalt slag are phase-oxidized into metal oxides, and the oxidation rate is more than 80%;

[0073] (2) Grinding: crushing, grinding and sieving the high-cobalt slag after roasting until the particles with a particle size of less than 0.074mm account for more than 90% of the mass, and obtain the roasting slag to be processed;

[0074] (3) Alkaline leaching: configure the concentration of glycine leaching agent to be 50g / L, use sodium hydroxide solution to adjust the pH of the leaching agent solution to 11; mix the prepared glycine leaching agent with the roasted slag to be treated at a liquid-solid ratio of 5:1 , heated to 40°C, and leached for 1 hour under m...

Embodiment 2

[0078] This embodiment provides a method for leaching zinc from the high-cobalt slag of hydrometallurgy, comprising the following steps:

[0079] (1) Oxidation roasting: put the high-cobalt slag into a high-temperature roasting furnace, and roast at 450°C for 60 minutes, so that the zinc and cobalt occurrences in the high-cobalt slag are phase-oxidized into metal oxides, and the oxidation rate is more than 90%;

[0080] (2) Grinding: crushing, grinding and sieving the high-cobalt slag after roasting until the particles with a particle size of less than 0.074mm account for more than 90% of the mass, and obtain the roasting slag to be processed;

[0081] (3) Alkaline leaching: configure the concentration of glycine leaching agent to be 100g / L, use sodium hydroxide solution to adjust the pH of the leaching agent solution to 11.5; mix the prepared glycine leaching agent with the roasted slag to be treated at a liquid-solid ratio of 10:1 , heated to 60°C, leached for 5 hours under ...

Embodiment 3

[0085] This embodiment provides a method for leaching zinc from the high-cobalt slag of hydrometallurgy, comprising the following steps:

[0086] (1) Oxidation roasting: put the high-cobalt slag into a high-temperature roasting furnace, and roast at 500°C for 90 minutes, so that the zinc and cobalt occurrences in the high-cobalt slag are phase-oxidized into metal oxides, and the oxidation rate is more than 95%;

[0087] (2) Grinding: crushing, grinding and sieving the high-cobalt slag after roasting until the particles with a particle size of less than 0.074mm account for more than 90% of the mass, and obtain the roasting slag to be processed;

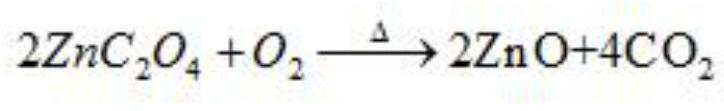

[0088] (3) Alkaline leaching: configure the concentration of glycine leaching agent to be 150g / L, use sodium hydroxide solution to adjust the pH of the leaching agent solution to 12; mix the configured glycine leaching agent with the roasted slag to be treated at a liquid-solid ratio of 15:1 , heated to 70°C, and leached for 15 hours u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com