Selective leaching agent and recycling method for metal components in positive electrode material

A cathode material and metal component technology, which is applied in the field of selective leaching agent and recovery of metal components in waste lithium ion battery cathode materials, can solve the problem of long recovery process, complicated impurity removal process, and inability of leaching agent for waste lithium ion battery. Recycling and other issues, to achieve the effect of selective separation, good selectivity, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A selective leaching agent for positive electrode materials, the leaching agent is a solution containing ammonia, ammonium sulfate and sodium sulfite, wherein C (NH 3 )=4mol / L, C(NH 4 + )=4mol / L, the concentration of sodium sulfite is 1mol / L.

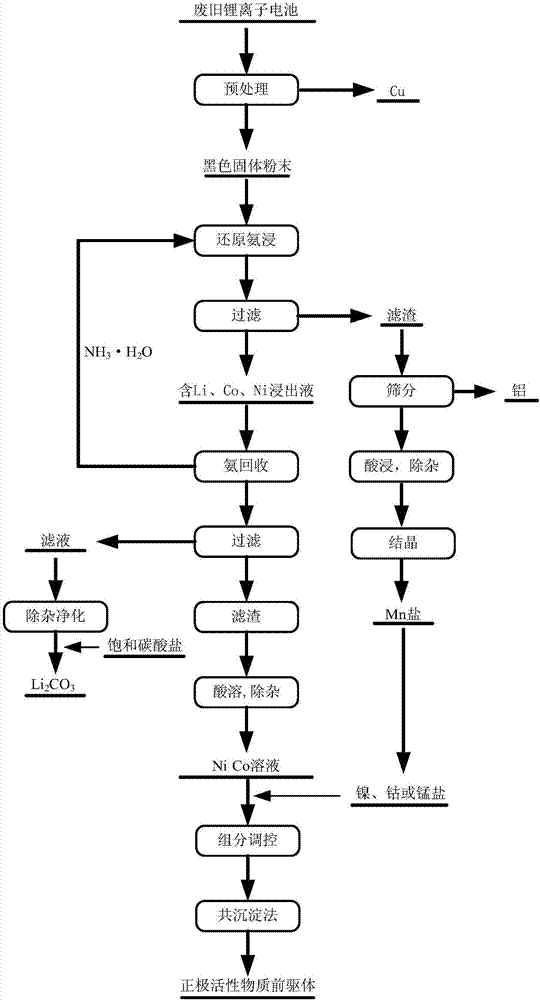

[0066] A method for selective leaching and recovery of metal components in waste lithium ion batteries, comprising the steps of:

[0067] (1) The waste lithium-ion battery is directly crushed and sieved, and after removing copper, the powder is obtained, and its metal composition is as shown in Table 1:

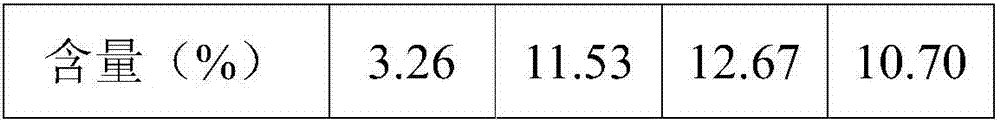

[0068] Metal composition of table 1 electrode powder

[0069] Metal

Al

Fe

Li

Ni

co

mn

content(%)

3.33

9.10

3.10

12.53

12.67

6.70

[0070] Take 5g of electrode powder and add it to a three-necked flask containing 100mL of a mixed solution of ammonia, ammonium sulfate and sodium sulfite. The concentration of sodium sulfite was 1 mol / L. The three-neck flask was p...

Embodiment 2

[0078] A selective leaching agent for positive electrode materials, the leaching agent is a solution containing ammonia, ammonium sulfate and sodium bisulfite, wherein C (NH 3 )=4mol / L, C(NH 4 + )=2mol / L, the concentration of sodium sulfite is 0.1mol / L.

[0079] A method for selective leaching and recovery of metal components in waste lithium ion batteries, comprising the steps of:

[0080] (1) Mechanically crush waste lithium-ion batteries, heat-treat at 400-800°C for 30-300 minutes, and sieve to remove metal Cu to obtain black electrode powder, whose metal composition is shown in Table 2;

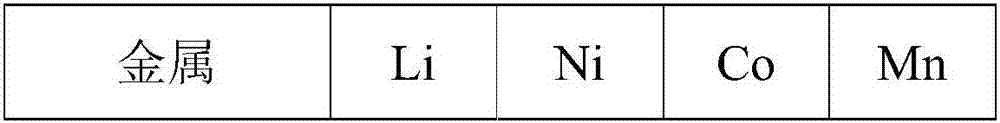

[0081] Metal composition of table 2 electrode powder

[0082] Metal

Al

Fe

Li

Ni

co

mn

content(%)

4.25

8.15

3.26

11.53

12.67

10.70

[0083] Take 1g of electrode powder and add it to a three-necked flask containing 100mL of a mixed solution of ammonia, ammonium sulfate and sodium bisulfite. The concentration of sodium bis...

Embodiment 3

[0090] A selective leaching agent for positive electrode materials, the leaching agent is a solution containing ammonia and ammonium sulfate, wherein C (NH 3 )=6mol / L, C(NH 4 + )=2mol / L.

[0091] A method for selective leaching and recovery of metal components in waste lithium ion batteries, comprising the steps of:

[0092] (1) Heat-treat waste lithium-ion batteries at 400-600°C for 30-300 minutes, crush and sieve to obtain electrode powder, and its metal composition is shown in Table 3:

[0093] Metal composition of table 3 electrode powder

[0094] Metal

Al

Fe

Li

Ni

co

mn

content(%)

5.22

5.31

3.16

13.53

11.67

8.70

[0095] Take 0.5g of electrode powder and add it into a three-necked flask containing 100mL of a mixed solution of ammonia and ammonium sulfate. The mixed solution does not contain a reducing agent, and the three-neck flask is placed in a constant temperature oil bath, the reaction temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com