Hydraulic throttle valve of high-pressure common rail oil injector

A high-pressure common rail and fuel injector technology, which is applied in the field of hydraulic throttle valves, can solve the problems of not being able to control the opening and closing delay of the fuel injector at the same time, and the actual effect is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

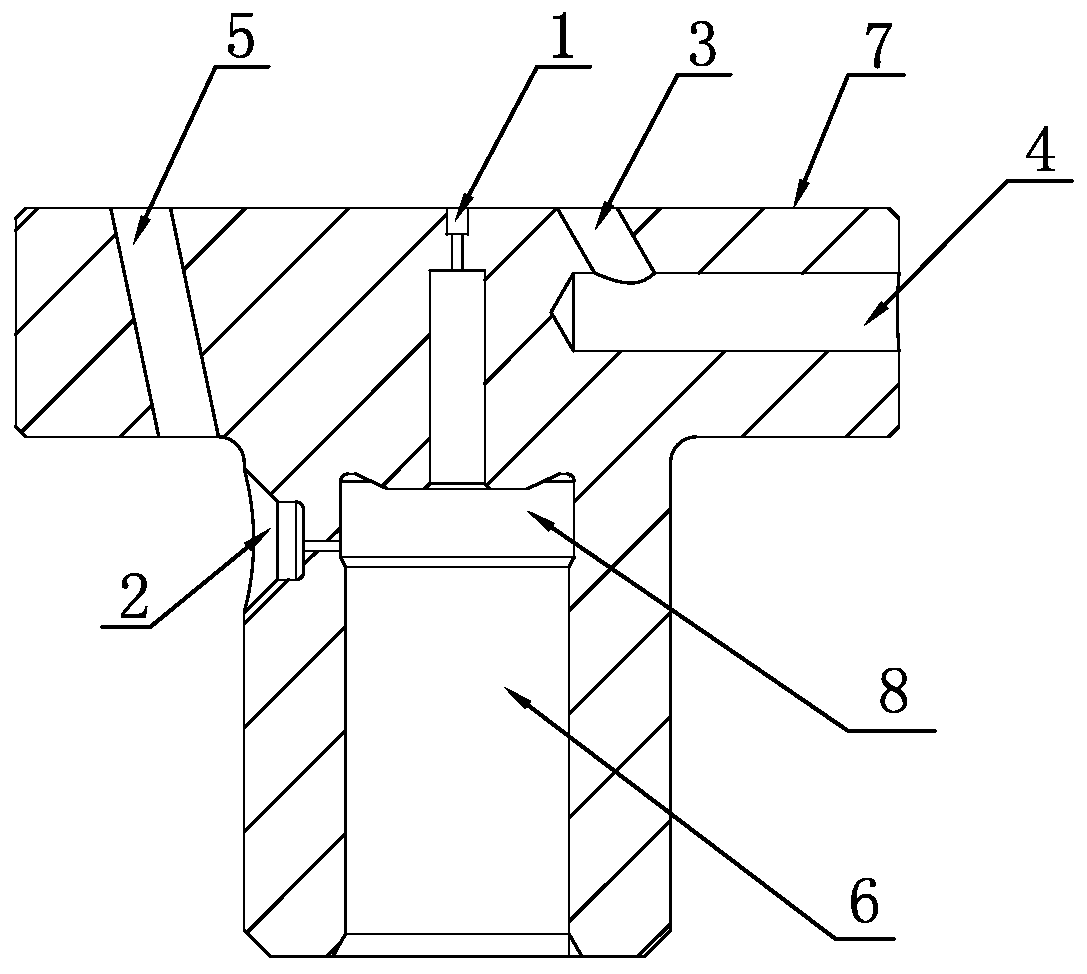

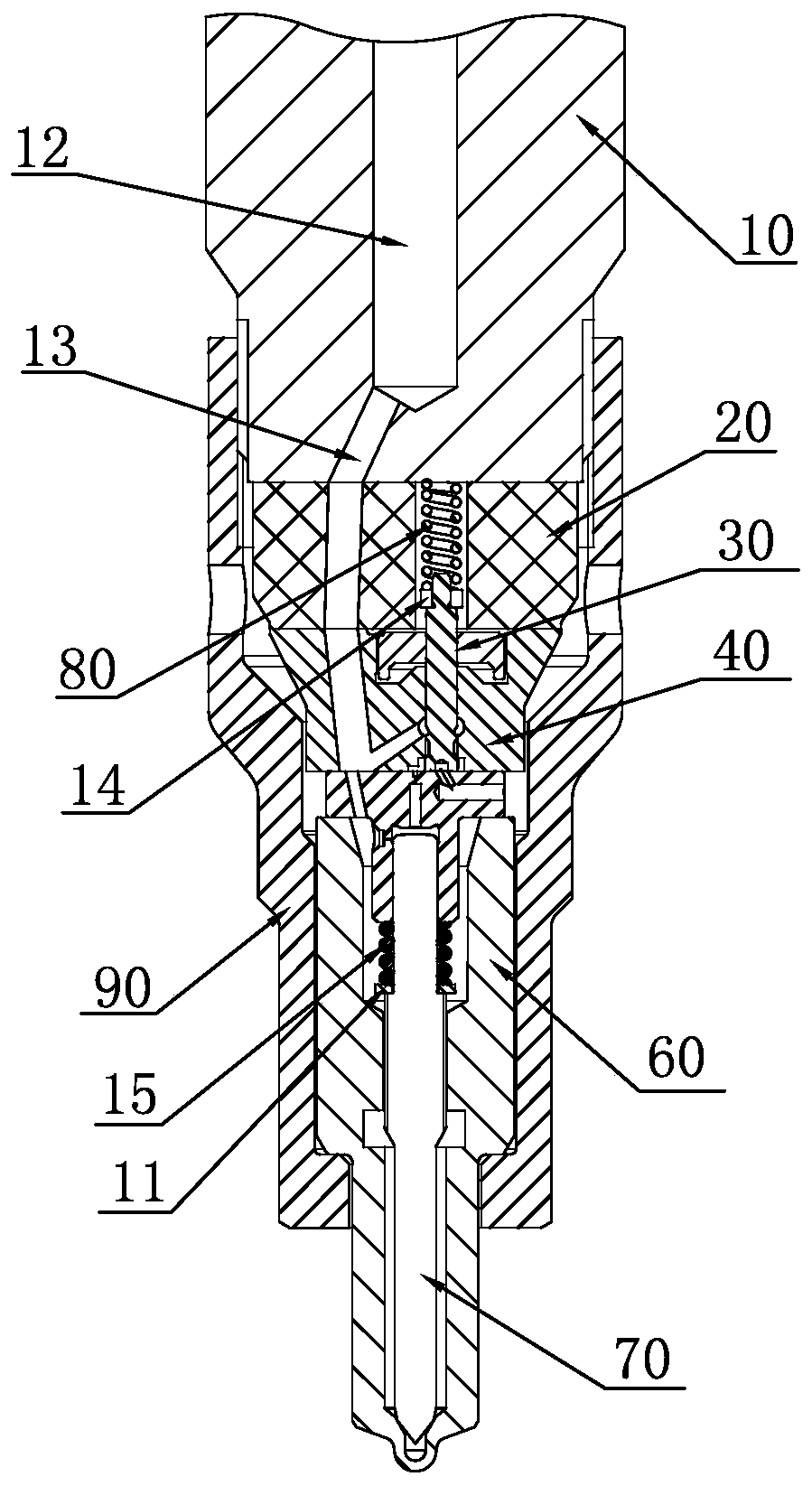

[0028] A hydraulic throttle valve for a high-pressure common rail injector, such as figure 1 As shown, it includes the throttle channel 1 on the end face, the throttle channel 2 on the side face, the first inclined channel 3 on the end face, the side channel 4 on the valve shoulder, the second inclined channel 5 on the end face, the guide hole 6 on the valve core, the upper end surface 7 of the valve core and the valve core The oil storage chamber 8, the throttle passage 1 on the end face, the valve core guide hole 6 and the valve core oil storage chamber 8 are arranged coaxially, the valve core oil storage chamber 8 is arranged between the valve core guide hole 6 and the end face throttle passage 1, and the side The throttling passage 2 communicates with the valve core oil storage chamber 8, the first inclined passage 3 on the end face communicates with the valve shoulder side passage 4, and the valve shoulder side passage 4 communicates with the low-pressure oil circuit; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com