Blasting method of IV-level massive kata-rocks with mussily-developing wide fracture faces

A cracked surface and messy technology, applied in blasting, earthwork drilling, mining equipment, etc., can solve problems such as difficulty in guaranteeing the construction period, small excavation footage, and increased risk of collapse, so as to ensure construction safety, reduce rock weathering, reduce The effect of blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The implementation background of this embodiment is that a high-speed railway double-track tunnel has a blasting section of 50 square meters and a total length of 7827.3m. Influenced by geological structures such as the Tianjiagou fault, joints and fissures are developed, the rock mass is broken, and the fissure surfaces are filled with calcite veins, so the self-stabilization ability of the surrounding rock is poor. After excavation, it was revealed that the lithology is gray-black sandy and carbonaceous shale, with thin to medium-thick layers. The rock mass is massive as a whole and partially broken. From time to time, fissure water is exposed and leaks along the fissures.

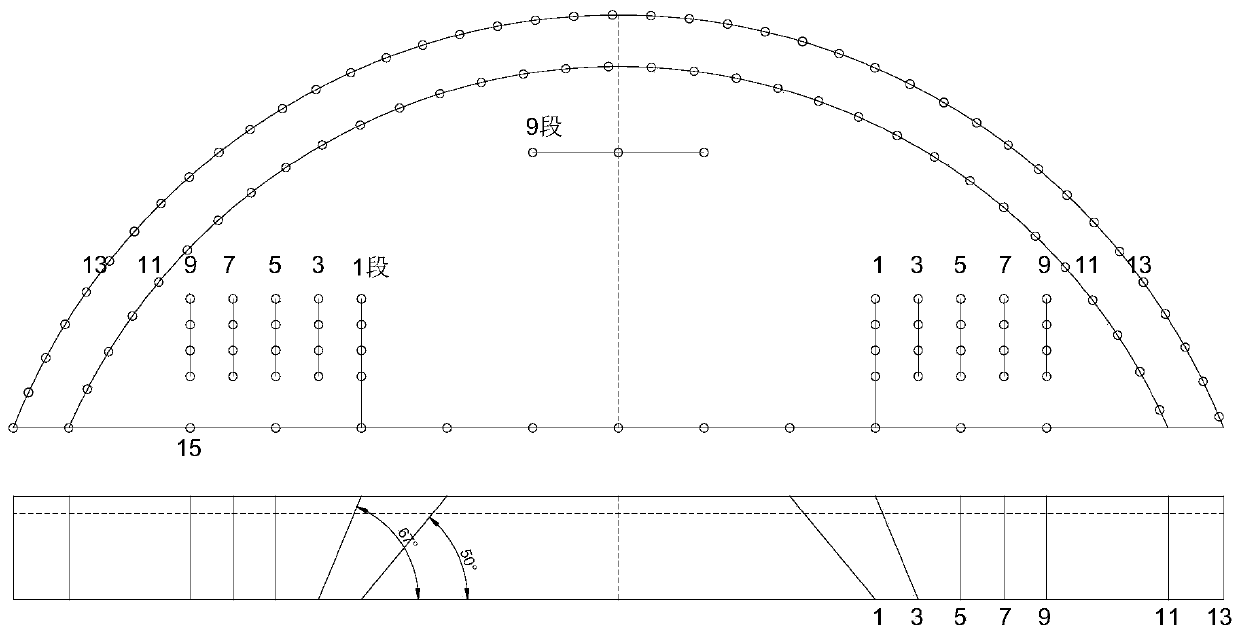

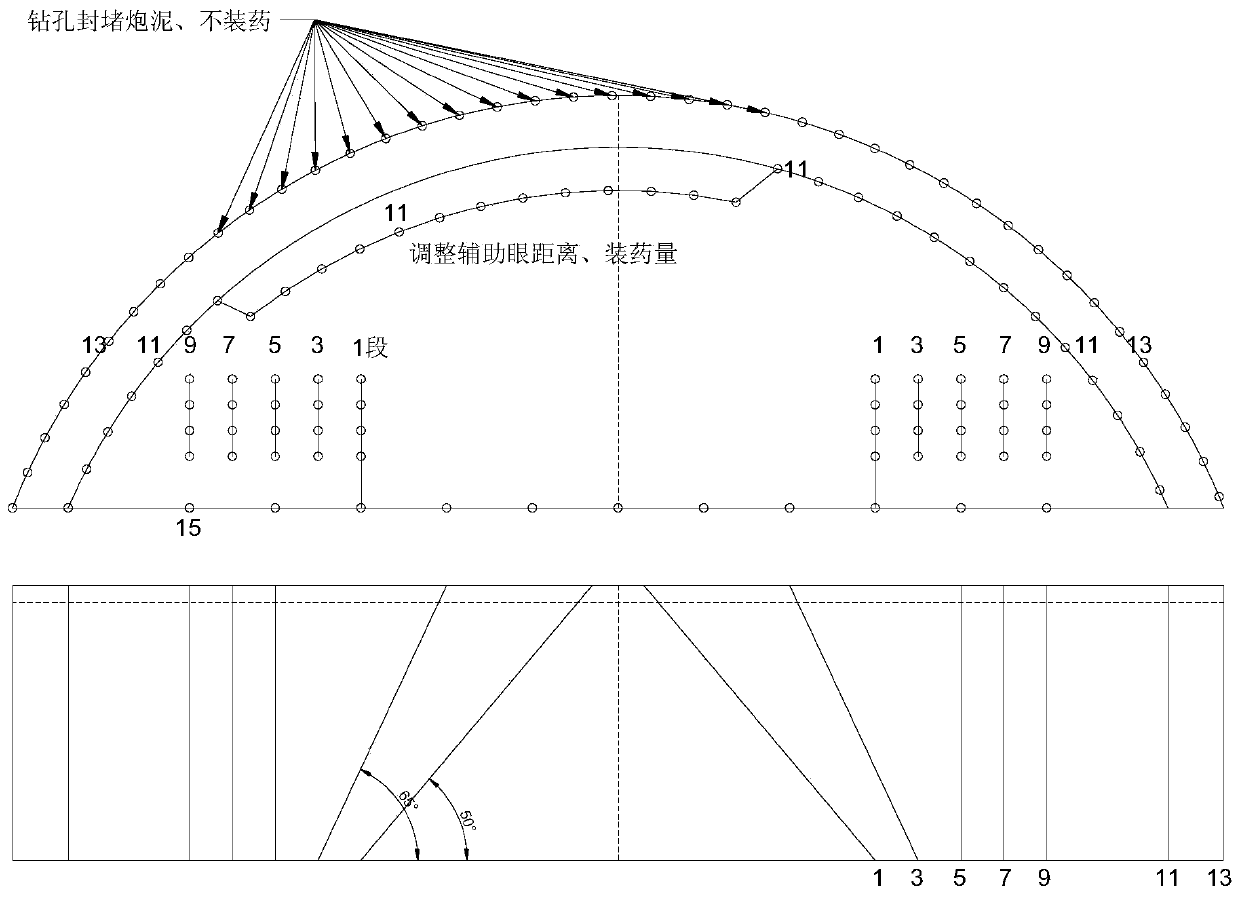

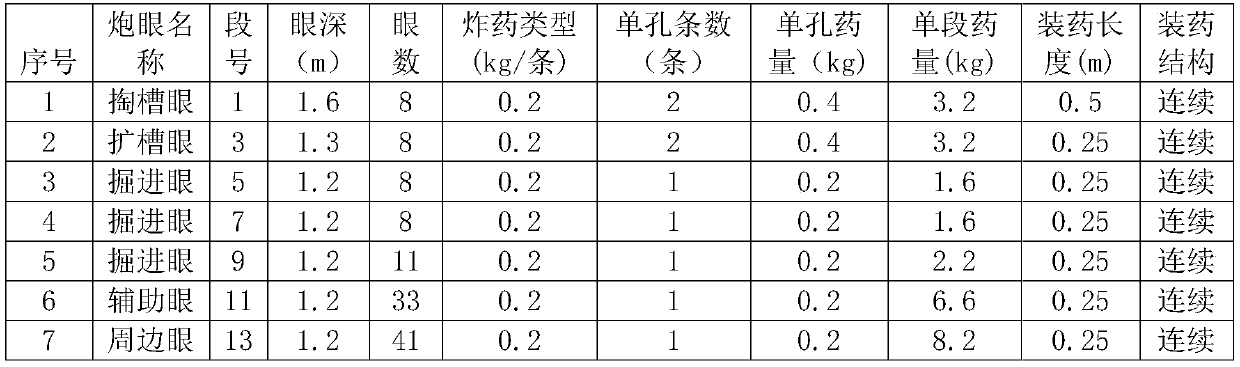

[0041] Such as figure 1 As shown, in the previous cycle, the original design scheme was constructed by the three-step drilling and blasting method, and the design scheme is as follows:

[0042] Explosives: use No. 2 rock emulsion explosives,

[0043] Detonator: use non-electric millisecond det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com