A multi-layer superimposed polymer composite light diffusion plate and its production process

A technology of composite light and diffuser, applied in layered products, synthetic resin layered products, optics, etc., can solve the problems of light efficiency, haze and poor light transmittance, and solve the problem of haze and light transmittance. Low, high color rendering, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

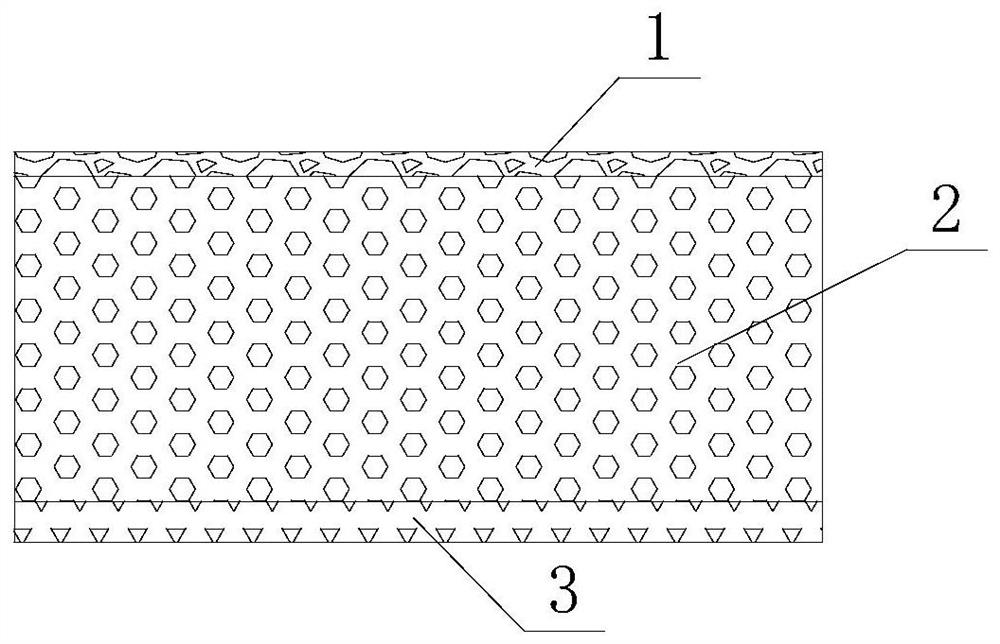

[0033] Such as figure 1 and figure 2As shown, the multi-layer superimposed polymer composite light diffusion plate provided in Embodiment 1 includes a base layer 2, a light incident layer 1 and an active layer 3, the light incident layer 1 is located on the first surface of the base layer 2, and the active layer 3 is located on the second surface of the base layer 2. The base layer 2, the light incident layer 1, and the active layer 3 are made of the same material, which can greatly reduce production costs and improve production efficiency, while in the prior art it is usually necessary to use multiple materials or various types of additives , to achieve optical effects such as high light efficiency, high haze, high uniformity, and high color rendering.

[0034] Relevant theoretical basis: According to the Beer-Lambert law A=lg(1 / T)=Kbc, b is the thickness of the absorbing layer, c is the concentration of the light-absorbing substance, and both b and c are proportional to t...

Embodiment 2

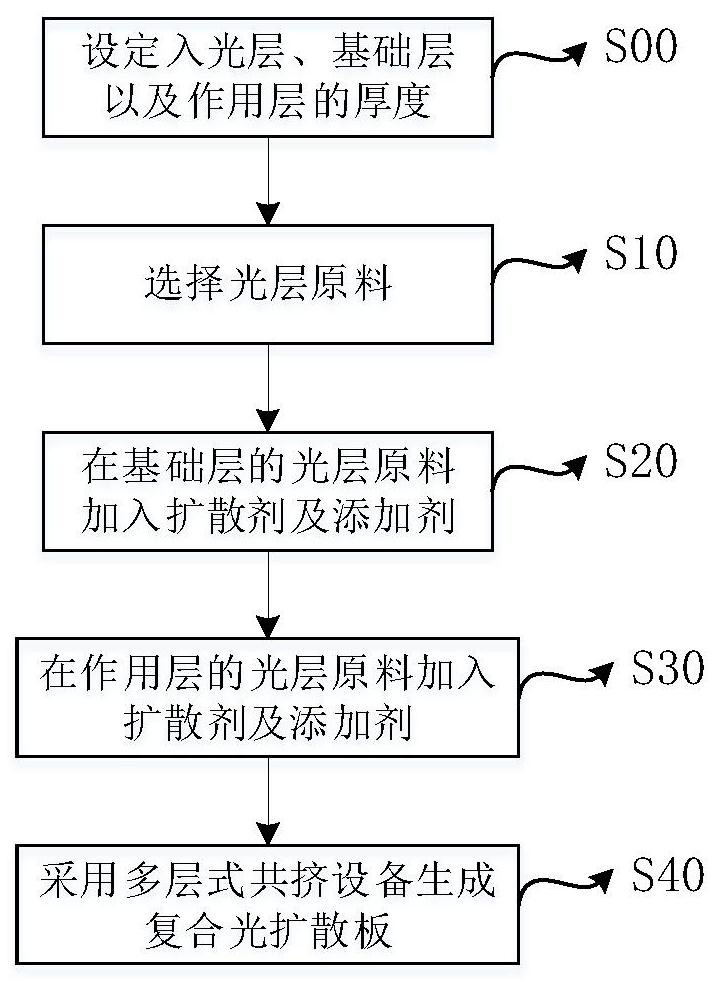

[0048] Such as figure 1 As shown, a production process for the above-mentioned multi-layer superimposed polymer composite light diffusion plate provided in Embodiment 2 is implemented according to the following steps:

[0049] The thicknesses of the light-incident layer 1 , the base layer 2 and the active layer 3 are set according to preset thicknesses.

[0050] One of the three materials of GPPS, PMMA and PC is selected as the raw material of the optical layer.

[0051] A first-type light-diffusing agent is added to the raw material of the optical layer of the base layer 2 to form the first-type light-diffusing particles.

[0052] A second-type light-diffusing agent is added to the raw material of the photo-layer of the active layer 3 to form second-type light-diffusing particles.

[0053] The addition amount of the first type of light diffusion agent and the first type of additive should make the first type of light diffusion particles in the base layer 2 be in the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com