A fault-tolerant control method and control system for multiple direct current motors in series

A DC motor, fault-tolerant control technology, applied in the direction of DC motor rotation control, control system, motor speed or torque control, etc., can solve the problems of poor real-time performance of motor control, complex control hardware circuits, and general control effects. Achieve the effects of improving accuracy, avoiding damage to the circuit due to increased circuit current, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

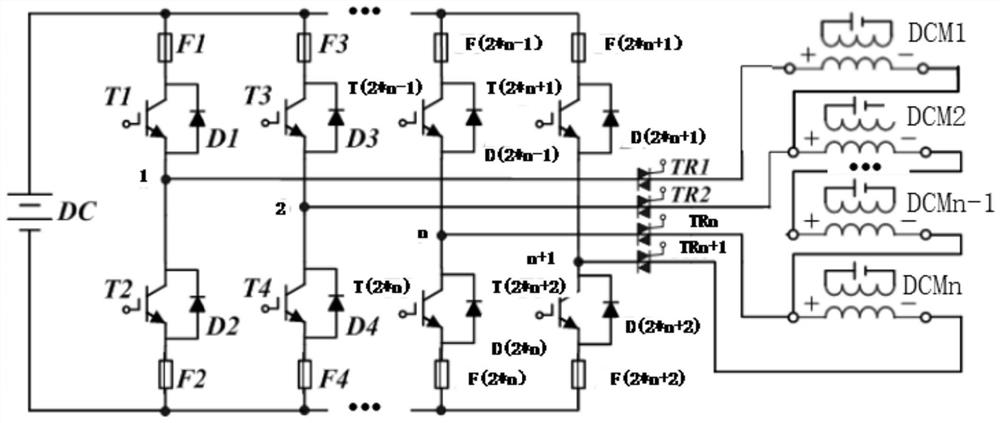

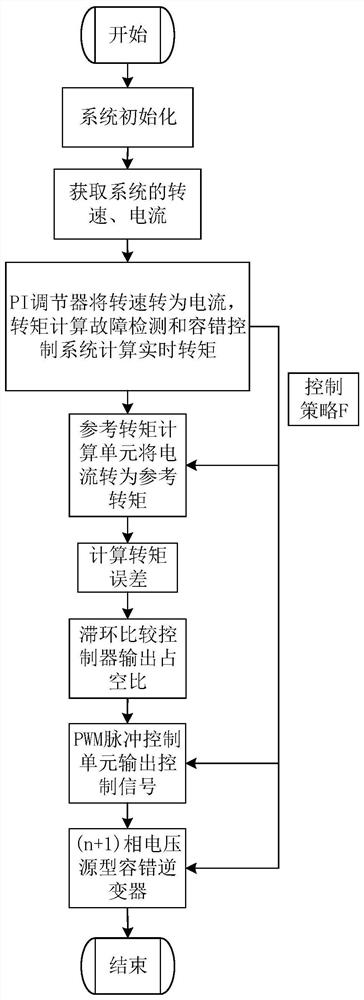

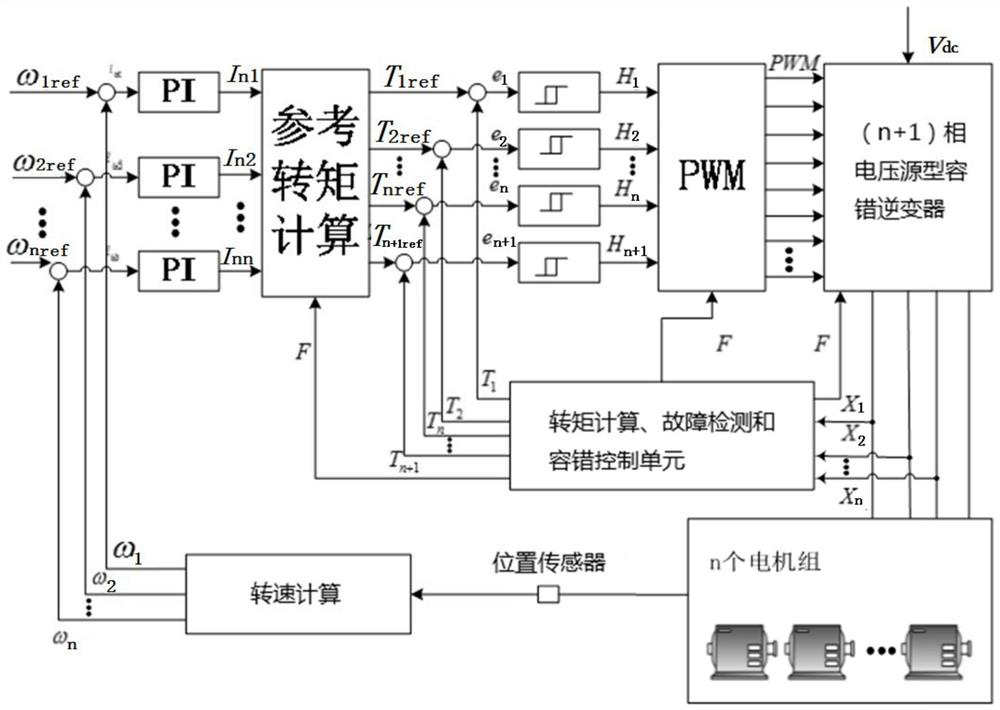

[0094] see figure 1 and figure 2 , the present invention provides a multi-DC motor series fault-tolerant control system, including n DC motors connected in series, n PI controllers, a reference torque calculation unit, and (n+1) torque hysteresis loops Comparing controller, and a PWM pulse width modulation unit, and (n+1) phase voltage source type fault-tolerant inverter, and torque calculation, fault detection and fault-tolerant control strategy unit, permanent magnet synchronous motor current detection sensor, and speed Position sensor, and DC power supply;

[0095] The input terminals of the reference torque calculation unit are respectively connected to n PI controllers, and the output terminals of the reference torque calculation unit are respectively connected to the input terminals of (n+1) torque hysteresis comparison controllers; the PWM pulse width modulation unit The input terminals of the (n+1) torque hysteresis comparison controllers are connected respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com