Stirring device for concrete cyclic production

A mixing device and concrete technology, applied in cement mixing devices, clay preparation devices, mixing operation control devices, etc., can solve the problems of waste of concrete raw materials, affecting the use efficiency, waste of water resources, etc., so as to reduce resource waves and improve utilization rate. , the effect of convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

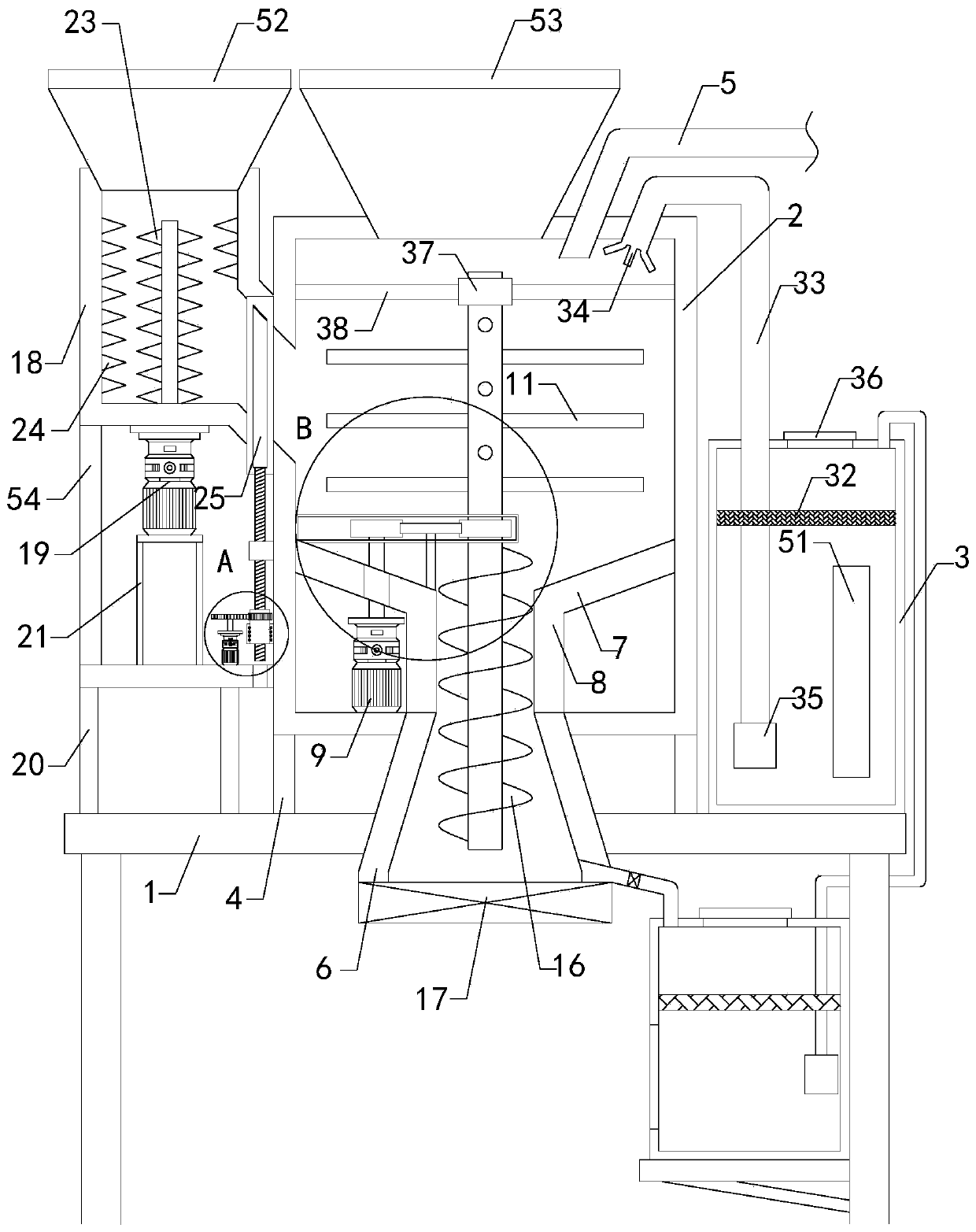

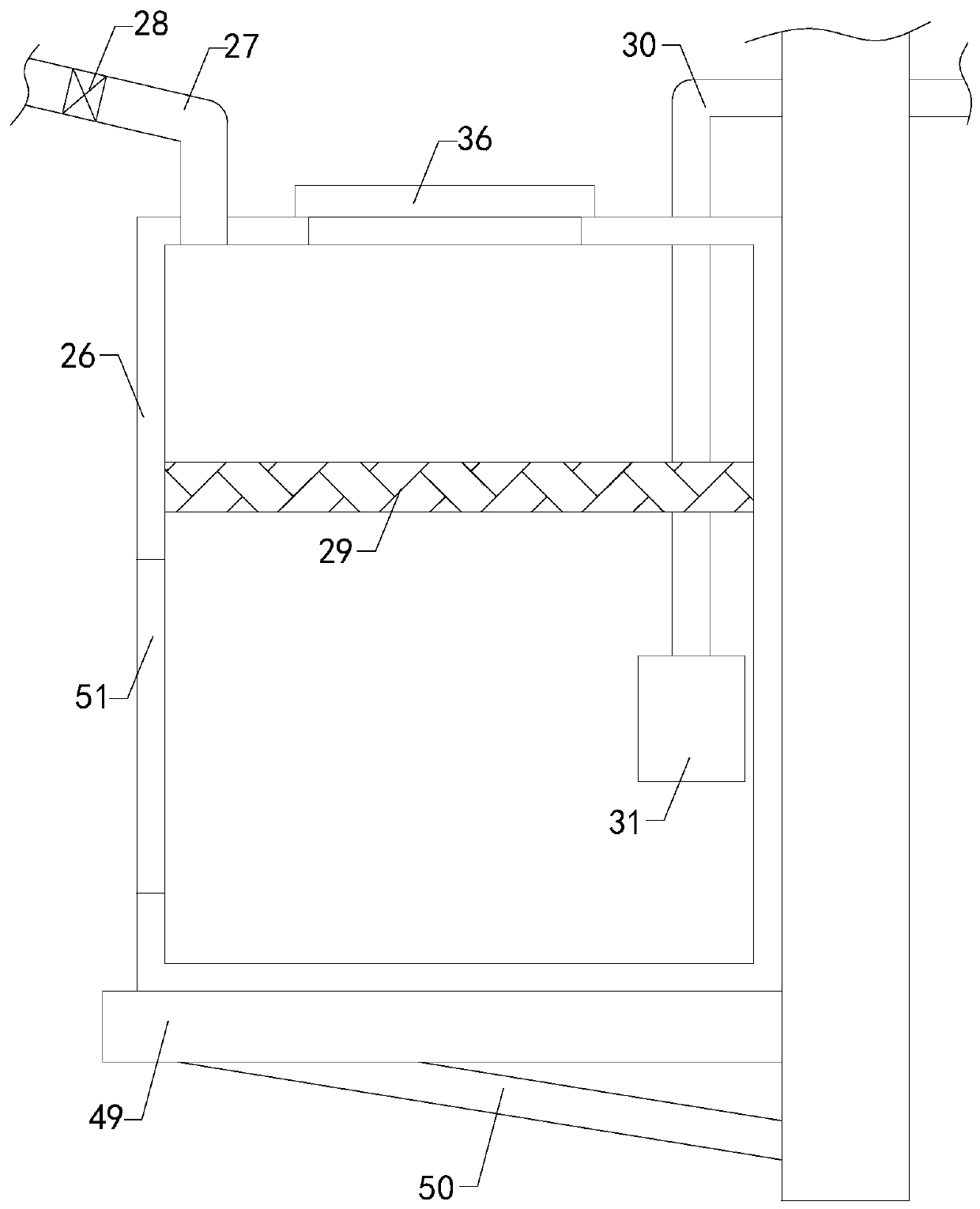

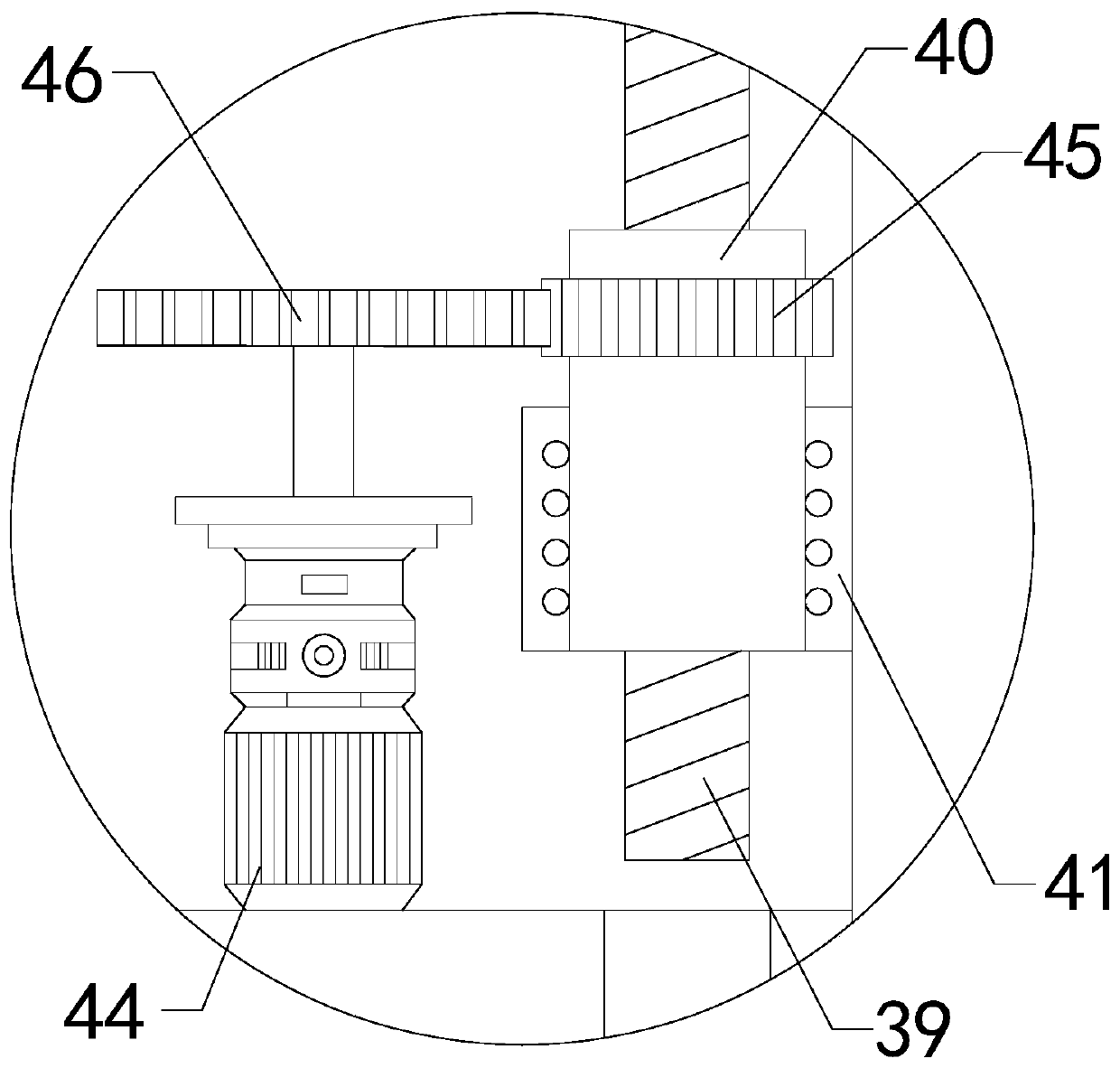

[0031] see Figure 1-6 , a mixing device for concrete circulation production, including a support frame 1, a mixing drum 2 and a water storage tank 3, the four corners of the bottom end of the mixing drum 2 are longitudinally connected with legs 4, and the bottom ends of the four legs 4 They are respectively connected to the four corners of the top middle area of the support frame 1, the top of the mixing drum 2 is provided with a water inlet pipe 5, the middle part of the support frame 1 is provided with a discharge hole that penetrates up and down, and the bottom end of the mixing drum 2 is connected A discharge hopper 6 is installed, the bottom of the discharge hopper 6 passes through the discharge hole and stretches out to the outside of the bottom of the support frame 1, the outer wall of the discharge hopper 6 is fixedly connected with the inner wall of the discharge hole, and the inside of the mixing drum 2 is set There is a funnel 7, the peripheral outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com