Mask ear belt machine

A technology of earbands and masks, which is applied in the field of mask production equipment, can solve problems such as missing welding, high work intensity, and high labor costs, and achieve the effects of high efficiency, short transfer stroke, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

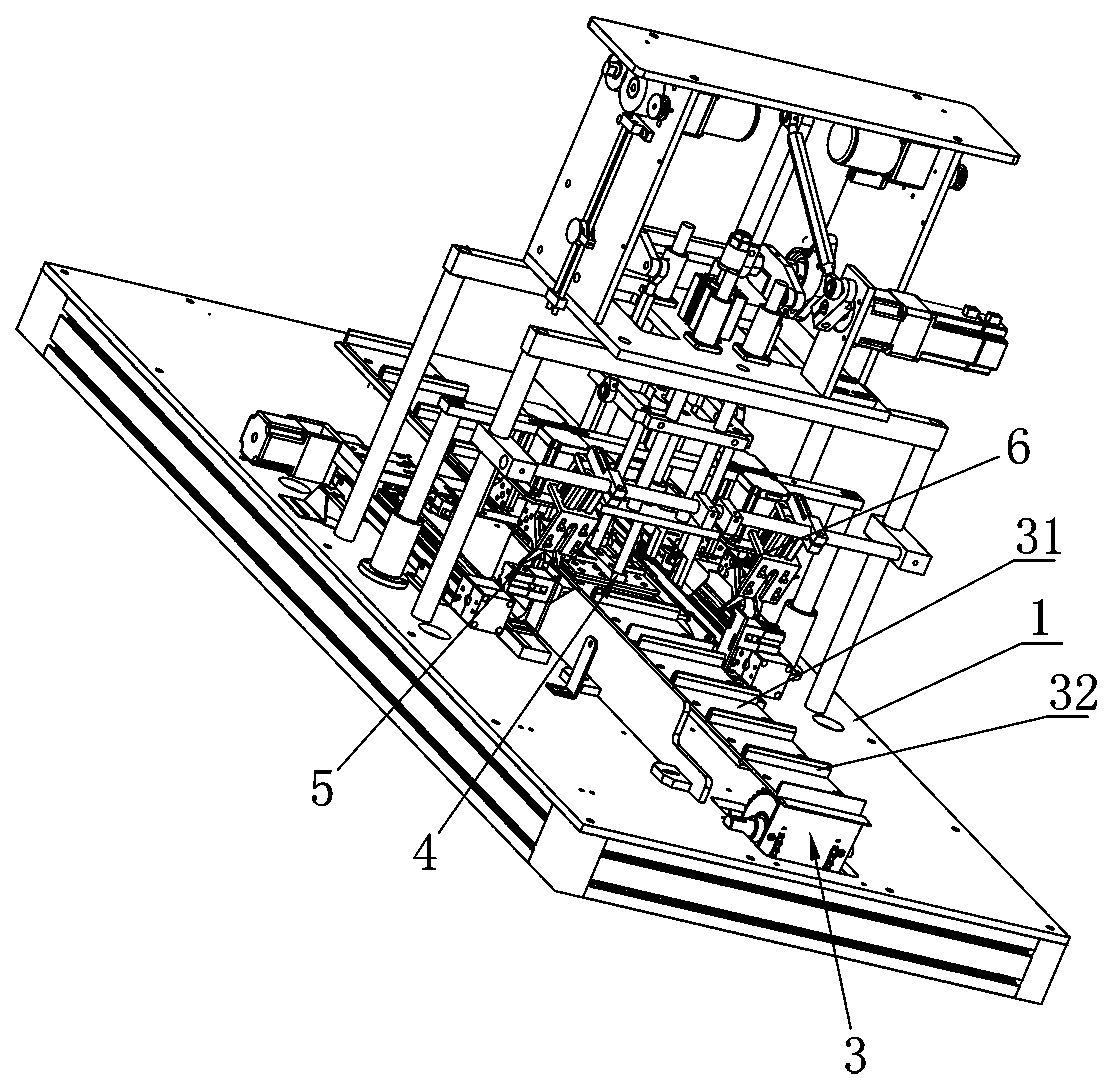

[0021] Such as figure 1 As shown, the mask earband machine includes a frame 1, and the frame 1 is provided with an earband welding station 2, a mask conveying mechanism 3, an earband welding mechanism 4, an earband cutting mechanism 5 and an earband clamping mechanism 6. The mask conveying mechanism 3 includes a mask conveyor belt 31 that sends the mask to the earband welding station. The mask conveyor belt 31 is provided with a mask limit plate 32 at intervals, and the mask is placed between the two mask limit plates. During the period, the mask conveyor belt transports the mask to the earband welding station to wait for the earband welding.

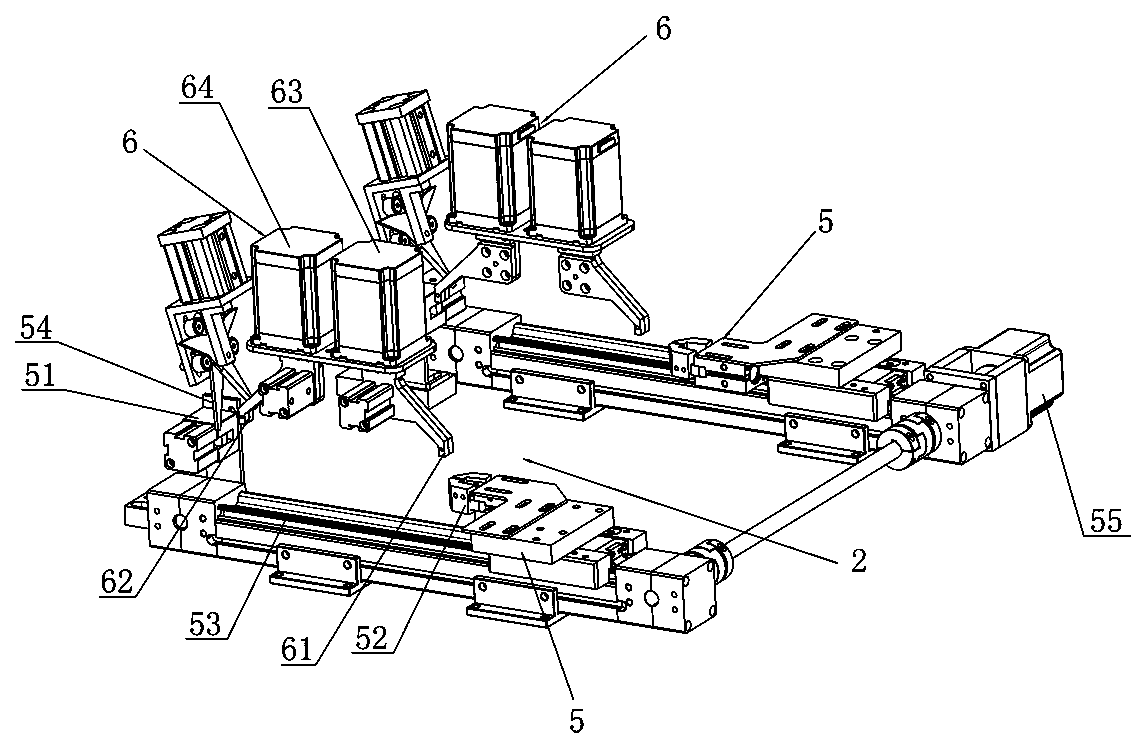

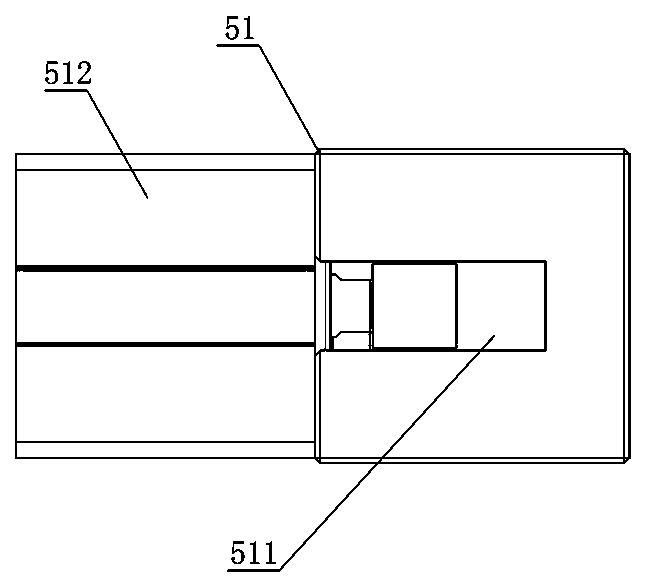

[0022] Such as figure 2 As shown, the earband cutting mechanism 5 is provided with two sets of left and right sides and is located on both sides of the earband welding station 2 respectively. The earband cutting mechanism 5 includes an earband inlet holder 51 and a pull earband holder 52 , moving guide rail 53 and cutting tool 54, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com