Backlight AOI automatic detection system based on LCD display screen

An automatic detection and display technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of low detection efficiency and production capacity, and achieve the effect of compact structure, improved detection efficiency, and smooth overall process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

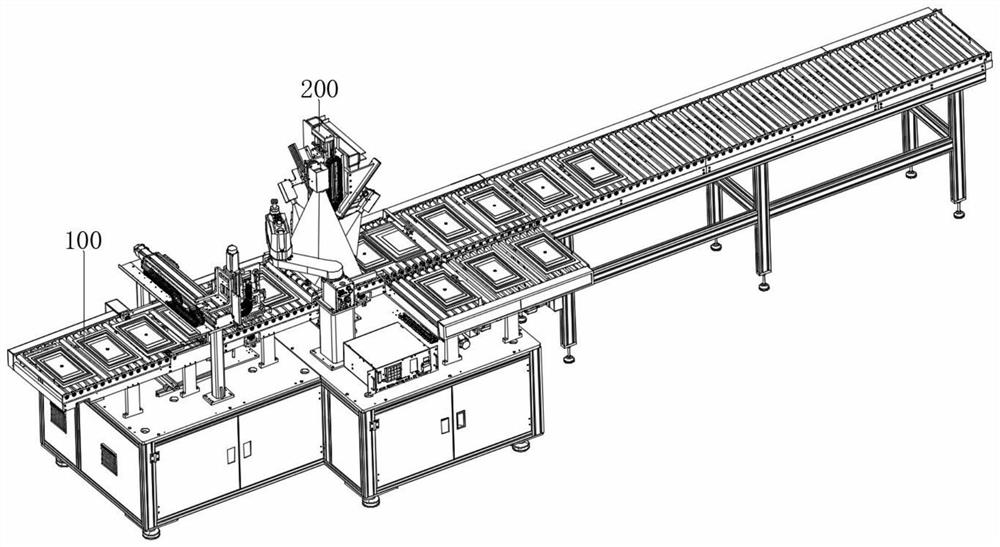

[0029] see Figure 1 to Figure 7 , the present invention provides an AOI automatic detection system based on LCD display backlight, including a conveying assembly 100 and a detection assembly 200, the conveying assembly 100 is used for conveying the LCD display screen, and the detection assembly 200 is used for the LCD display screen backlight module to perform AOI automatic detection .

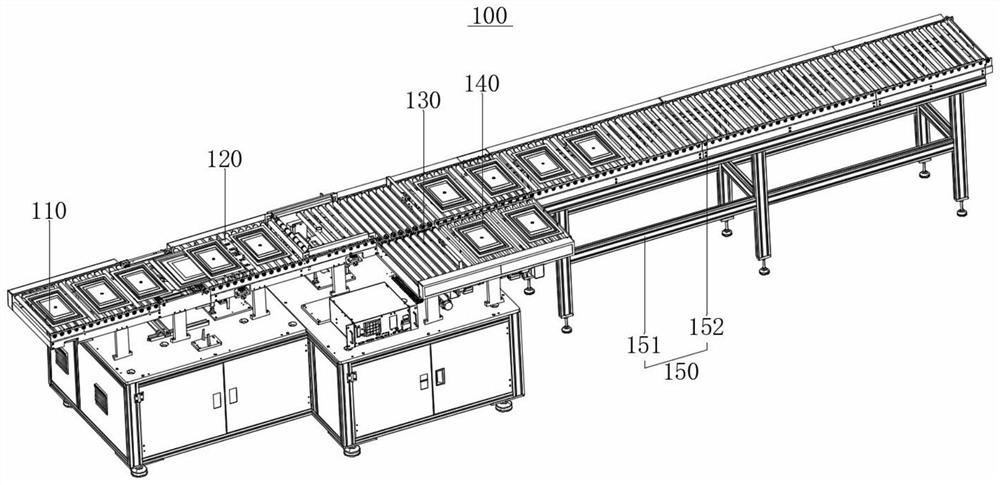

[0030] see figure 2 , the conveying assembly 100 includes a main conveyor 110, two sets of lifting parts 120, a non-conforming product translation part 130 and a side conveyor 140, the two sets of lifting parts 120 are arranged on the main conveyor 110, and the non-conforming product translation parts 130 are fixedly connected to The tail end of the main conveyor 110 and the side conveyor 140 are arranged on one side of the tail end of the main conveyor 110 . Wherein, the side conveyor 140 and the main conveyor 110 are arranged side by side, and the reject translation member 130 can move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com