Porous iron oxide negative electrode material and preparation method and application thereof

A negative electrode material, iron oxide technology, applied in the field of porous iron oxide negative electrode materials and its preparation, can solve the problems of poor rate capability and poor cycle capacity of negative electrode materials, and achieve improved cycle life, good electrochemical performance, and uniform morphology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a porous iron oxide negative electrode material, the preparation method of which is:

[0028] 42mg of fumaric acid and 160mg of Fe(NO 3 ) 3 9H 2 O (containing 95.8mgFe (NO 3 ) 3 ) were mixed in 8 mL of DMF to make a homogeneous precursor solution. Add 4 mg DMAP and stir at room temperature for 45 min, then place at 80°C for 20 min. Centrifuge, wash the obtained product with DMF and methanol, dry it in a 60°C drying oven for 24 hours, and then place it in a muffle furnace for calcination at 400°C for 20 minutes to obtain 31.7 mg of the initial product;

[0029] The obtained primary product was ground and mixed with 26 mg of hepta(2,3,6-tri-O-methyl)-β-cyclodextrin and 21 mg of β-cyclodextrin, and then calcined at 400° C. for 20 minutes under a hydrogen-argon mixed gas atmosphere.

Embodiment 2

[0031] This embodiment provides a porous iron oxide negative electrode material, the preparation method of which is:

[0032] The reactants 50mg terephthalic acid and 50mg fumaric acid were mixed with 200mg anhydrous ferric nitrate in 10.5mL DMF, then 10mg DMAP was added and stirred at room temperature for 30min, then placed in a drying oven at 60°C for 30min. Centrifuge, wash the obtained product with DMF and methanol, dry it in a drying oven at 100°C for 12 hours, and then place it in a muffle furnace at 500°C for 10 minutes to obtain 66.1 mg of the initial product;

[0033] The resulting primary product was mixed with 66mg 2-hydroxypropyl-β-cyclodextrin, 33mg (2-hydroxypropyl)-γ-cyclodextrin, 33mg 2,6-di-O-methyl-β-cyclodextrin Grinding and mixing are carried out, and calcined at 500° C. for 30 minutes under a hydrogen-argon gas mixture atmosphere.

Embodiment 3

[0035] This embodiment provides a porous iron oxide negative electrode material, the preparation method of which is:

[0036] The reactants 20mg terephthalic acid and 200mg anhydrous ferric nitrate were mixed in 2.1mL DMF, then 0.2mg DMAP was added and stirred at room temperature for 60min, then placed in a dry oven at 120°C for 10min. Centrifuge, wash the obtained product with DMF and methanol, dry it in a drying oven at 80°C for 18 hours, and then place it in a muffle furnace at 300°C for 20 minutes to obtain 66.0 mg of the initial product;

[0037] The obtained primary product was ground and mixed with the calcined product and 16.5 mg of γ-cyclodextrin and 16.5 mg of methyl-β-cyclodextrin, and calcined at 300° C. for 10 min under a nitrogen atmosphere.

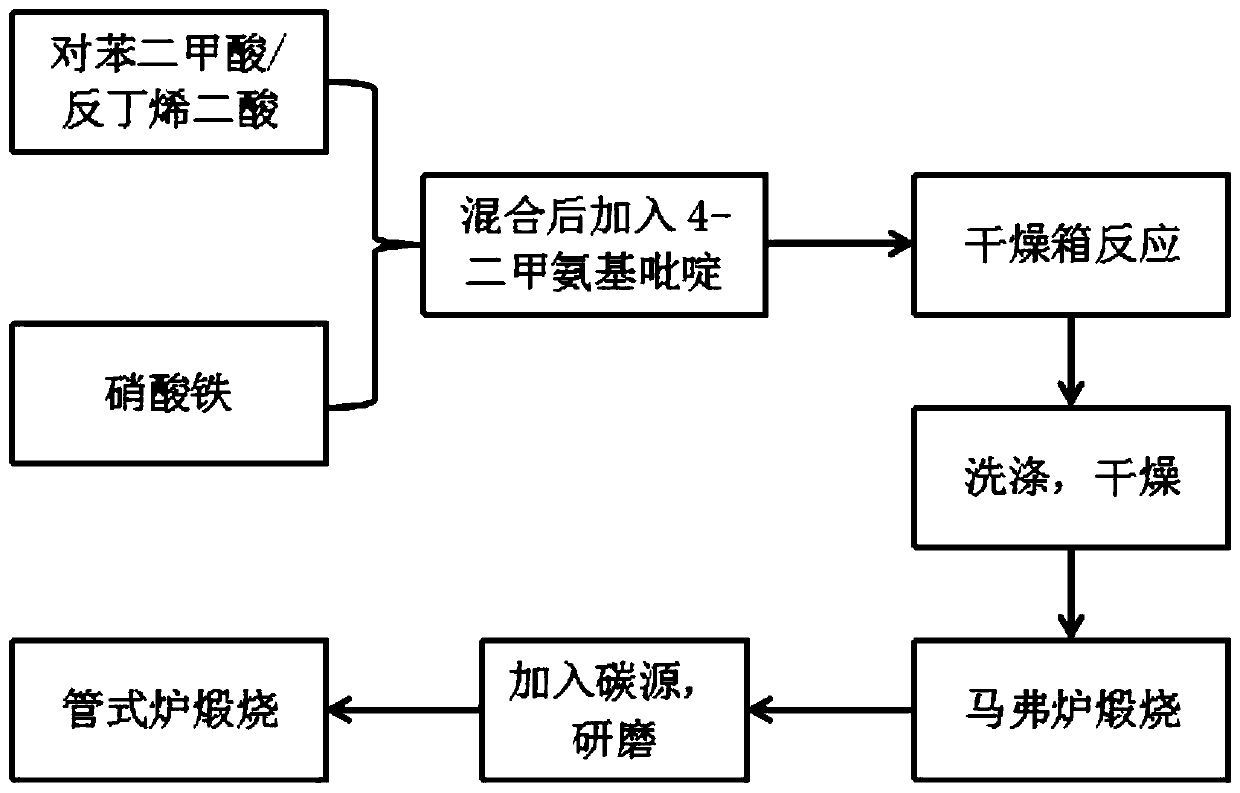

[0038] The process flow chart of embodiment 1~3 is as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com