Underwater equipment deploying and retracting device, laying method and recycling method based on ROV

A technology for underwater equipment and retractable devices, which is applied to underwater operation equipment, underwater ships, transportation and packaging, etc., can solve the problems of low operation efficiency, inaccurate positioning, and difficult operation, and achieves fast installation and operation. The effect of strong carrying capacity, saving construction and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

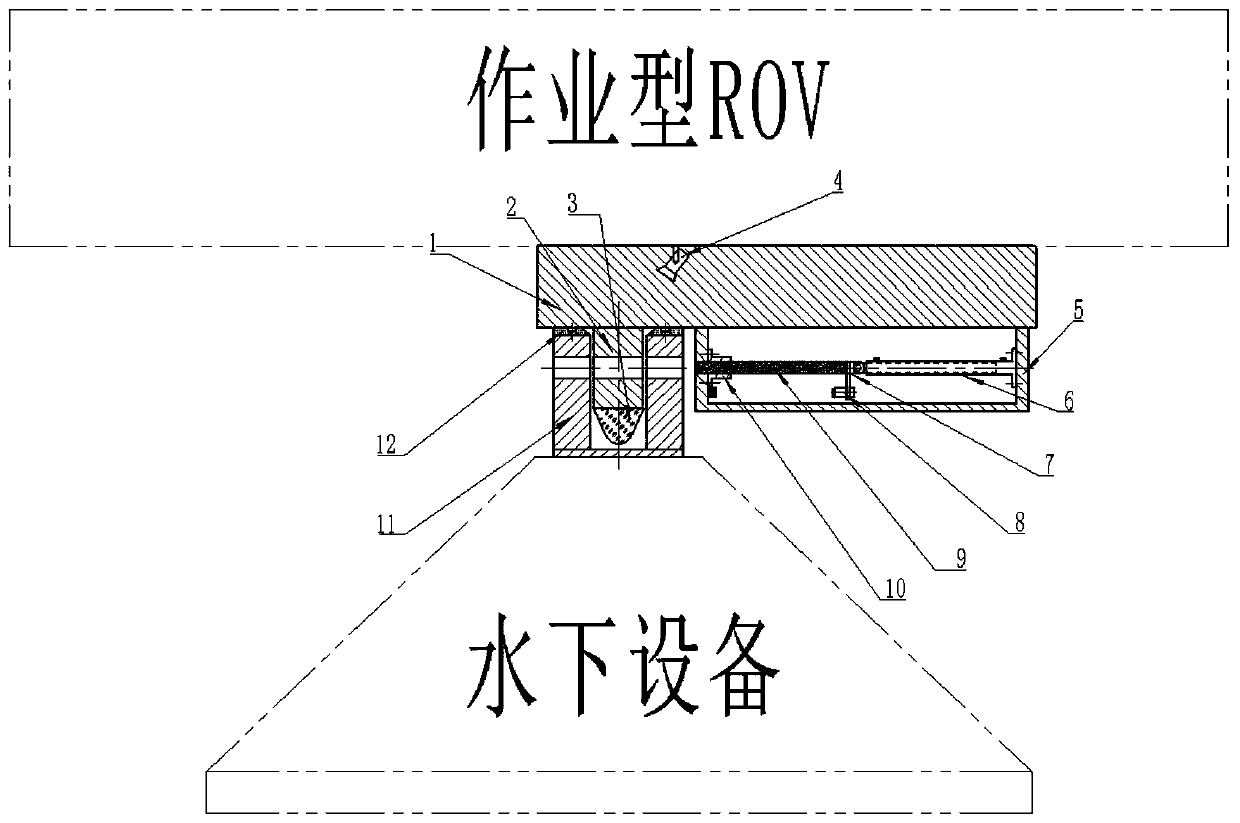

[0065] An ROV-based underwater equipment retracting device includes an ROV-end connecting part and an equipment-end connecting part. The connecting part at the ROV end is connected to the ROV load-bearing frame through bolts, etc., and transmits the lifting weight to the main lifting point of the ROV body, and has the function of combining and locking the lifting points. The connecting part of the equipment end is connected with the load-bearing part of the top center of the equipment body through the welding process, and has the function of combining lifting points. The overall installation is shown as figure 1 shown.

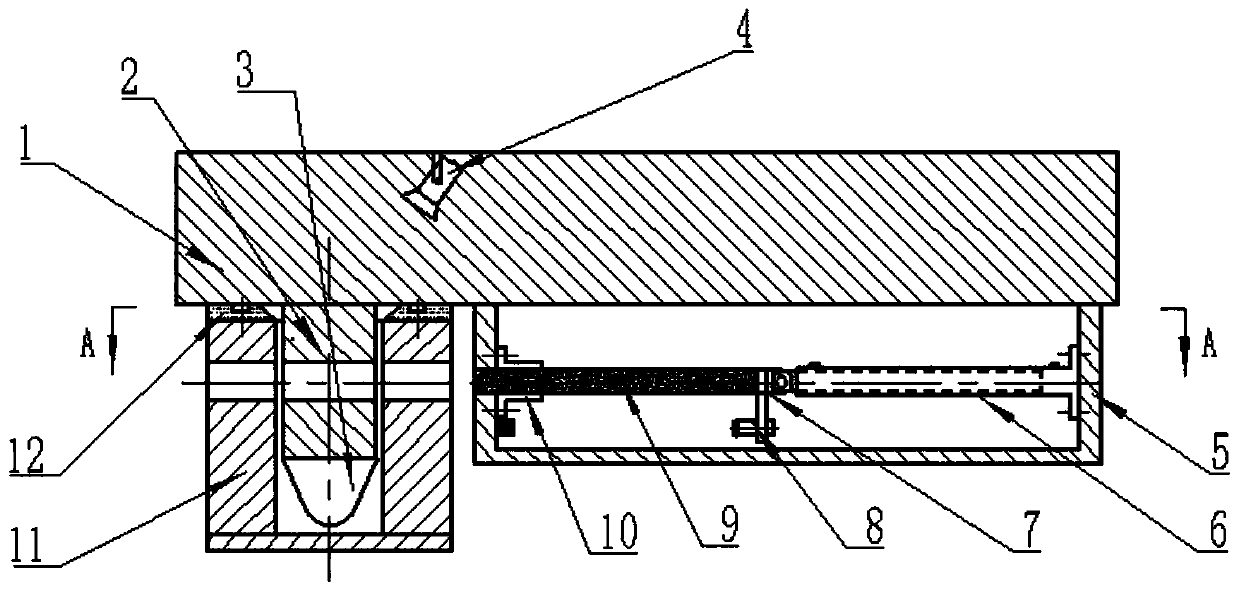

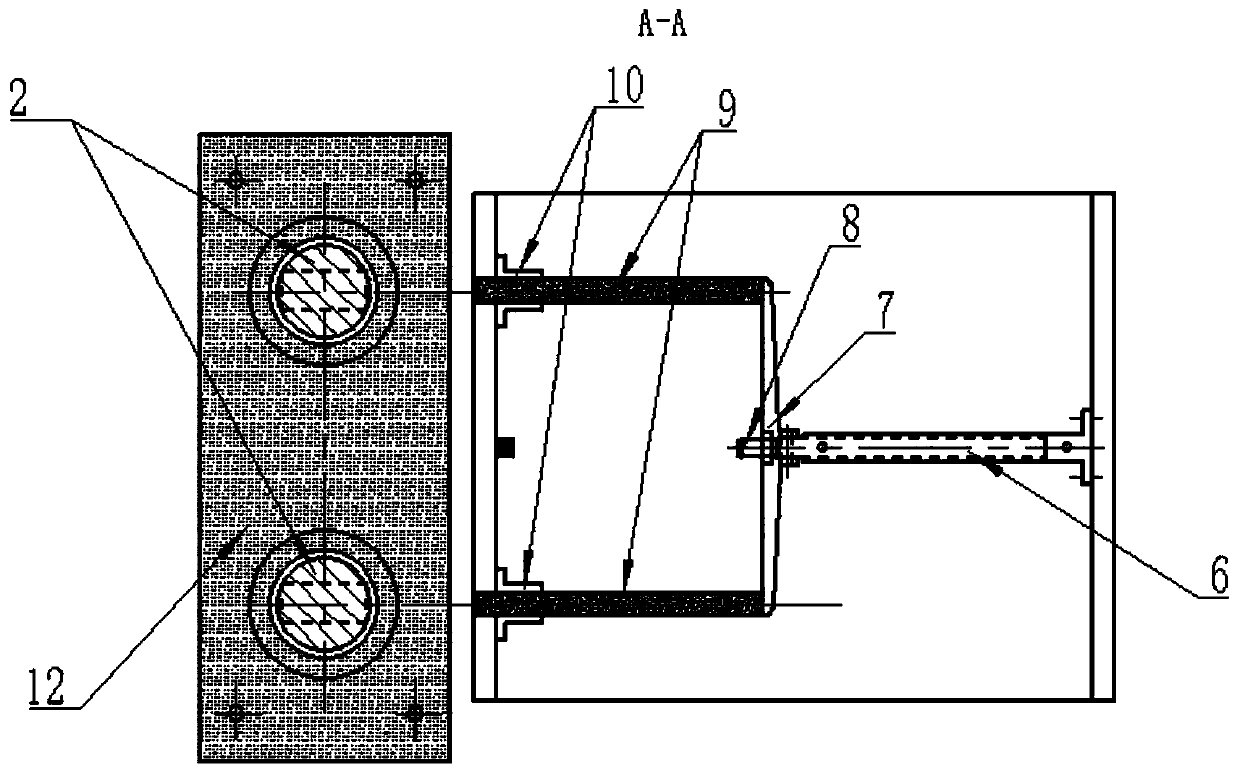

[0066] The connecting part of the ROV end consists of a main frame 1, two lifting columns 2, a guide body 3, an underwater docking camera 4, a support body 5, a locking cylinder 6, a connecting body 7, a contact sensor 8, two lock shafts 9 and two The guide body 3 is generally made of nylon material, which is connected with the lifting column 2 and has a gui...

Embodiment 2

[0076] According to the device of embodiment 1, the steps of the underwater equipment deployment method are as follows:

[0077] Step 1: Operate the ROV deployment crane system to lift the ROV from the deck to the deployment height; install the connecting parts of the ROV end to the load-bearing part of the ROV chassis as a whole through bolts, etc.

[0078] Step 2: Connect the inlet and outlet ports of the locking cylinder 6 to the valve box of the ROV operation tool through the high-pressure oil pipe, retract the telescopic rod of the locking cylinder 6 through the ROV console; connect the underwater docking camera 4 and the contact sensor 8 Connect to the reserved interface of the ROV electrical interface box through a watertight cable, and display the monitoring screen on the monitor.

[0079]Step 3: Move the underwater equipment to be deployed under the ROV, operate the ROV deployment crane to move the horizontal position of the ROV, and connect the connecting parts at th...

Embodiment 3

[0085] According to the device of embodiment 1, the underwater equipment recovery method steps are as follows:

[0086] Step 1: Lift the ROV from the deck to the deployment height by operating the deployment crane system of the ROV; install the connecting parts of the ROV end to the bearing part of the chassis of the ROV through bolts, and get ready;

[0087] Step 2: Connect the oil inlet and oil return port of the locking cylinder 6 to the valve box of the ROV's operation tool through the high-pressure oil pipe, and retract the telescopic rod of the locking cylinder 6 through the console of the ROV; The camera 4 and the contact sensor 8 are connected to the reserved interface of the electrical interface box of the ROV through a watertight cable to obtain a monitoring picture;

[0088] Step 3: Deploy the ROV into the water, fly to its vicinity according to the precise longitude and latitude when the underwater equipment is deployed, turn on the underwater docking camera 4, obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com