A conveying device for building materials

A technology for conveying devices and building materials, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of incomplete conveying device technology, small number of light building material boards, waste of light building material boards, etc., and achieve a small footprint , Conducive to placing and conveying, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

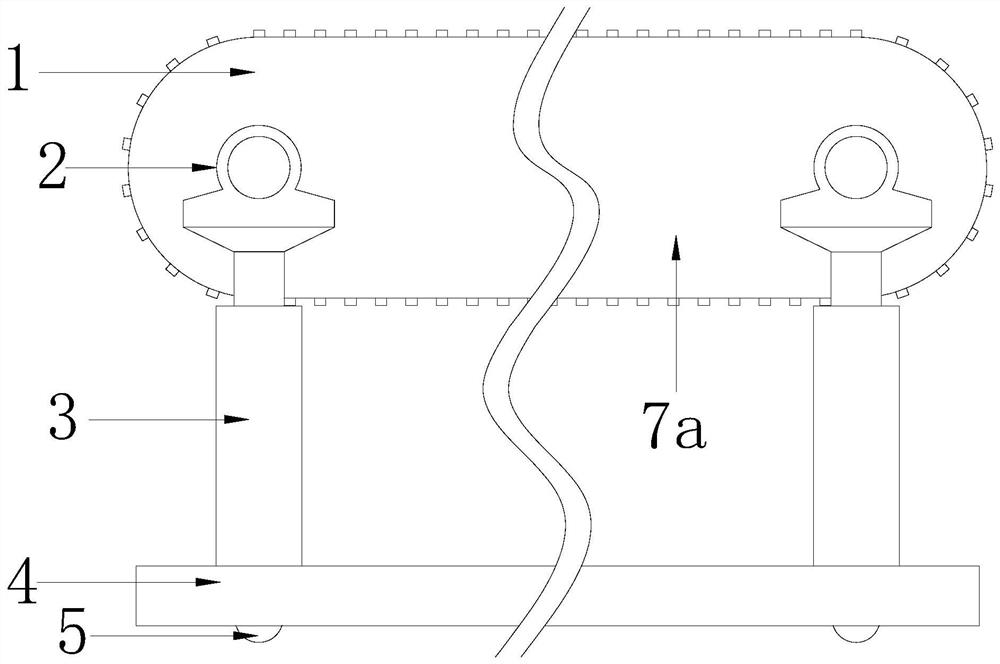

[0037] see figure 1 , the present invention provides a technical solution of a conveying device for building materials: its structure includes a conveying mechanism 1, a support seat 2, a hydraulic cylinder 3, a base 4, and universal wheels 5, and universal wheels are installed on the bottom of the base 4 5. The four directions of the top surface of the base 4 are vertically connected with a hydraulic cylinder 3, the hydraulic cylinder 3 is connected with the conveying mechanism 1 through the support seat 2, the conveying mechanism 1 is located above the base 4, and the hydraulic cylinder The setting of 3 makes conveying mechanism 1 can convey in parallel, can convey upwards, also can convey downwards.

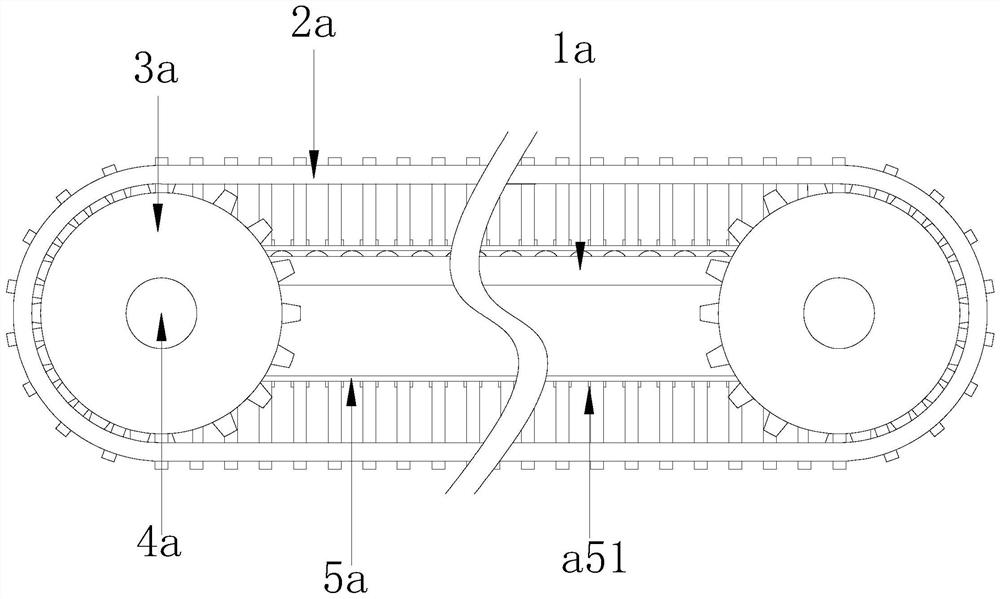

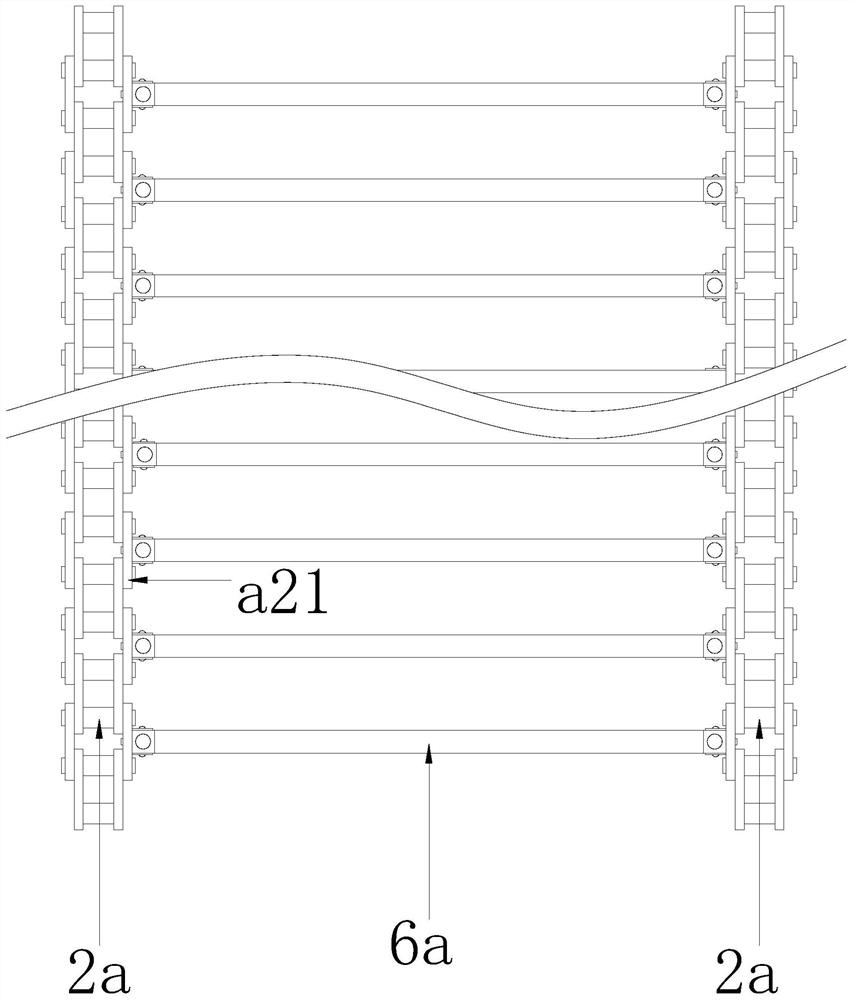

[0038] see Figure 1-2, the conveying mechanism 1 includes a supporting roller assembly 1a, a chain 2a, a sprocket 3a, a roller shaft 4a, a conveyor belt 5a, a lightweight partition 6a, and a protective cover 7a, and both inner ends of the conveyor belt 5a are equipped with ...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution of a conveying device for building materials: its structure includes a conveying mechanism 1, a support seat 2, a hydraulic cylinder 3, a base 4, and universal wheels 5, and universal wheels are installed on the bottom of the base 4 5. The four directions of the top surface of the base 4 are vertically connected with a hydraulic cylinder 3, the hydraulic cylinder 3 is connected with the conveying mechanism 1 through the support seat 2, the conveying mechanism 1 is located above the base 4, and the hydraulic cylinder The setting of 3 makes conveying mechanism 1 can convey in parallel, can convey upwards, also can convey downwards.

[0044] see Figure 1-2 , the conveying mechanism 1 includes a supporting roller assembly 1a, a chain 2a, a sprocket 3a, a roller shaft 4a, a conveyor belt 5a, a lightweight partition 6a, and a protective cover 7a, and both inner ends of the conveyor belt 5a are equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com