Fixed-length detection method, system and storage medium for textile equipment

A textile equipment and detection method technology, applied in the field of systems and storage media, and fixed-length detection methods for textile equipment, can solve the problems of high labor intensity, low yarn detection efficiency, and inability to accurately detect yarns, etc., to achieve Improved Accuracy, Improved Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

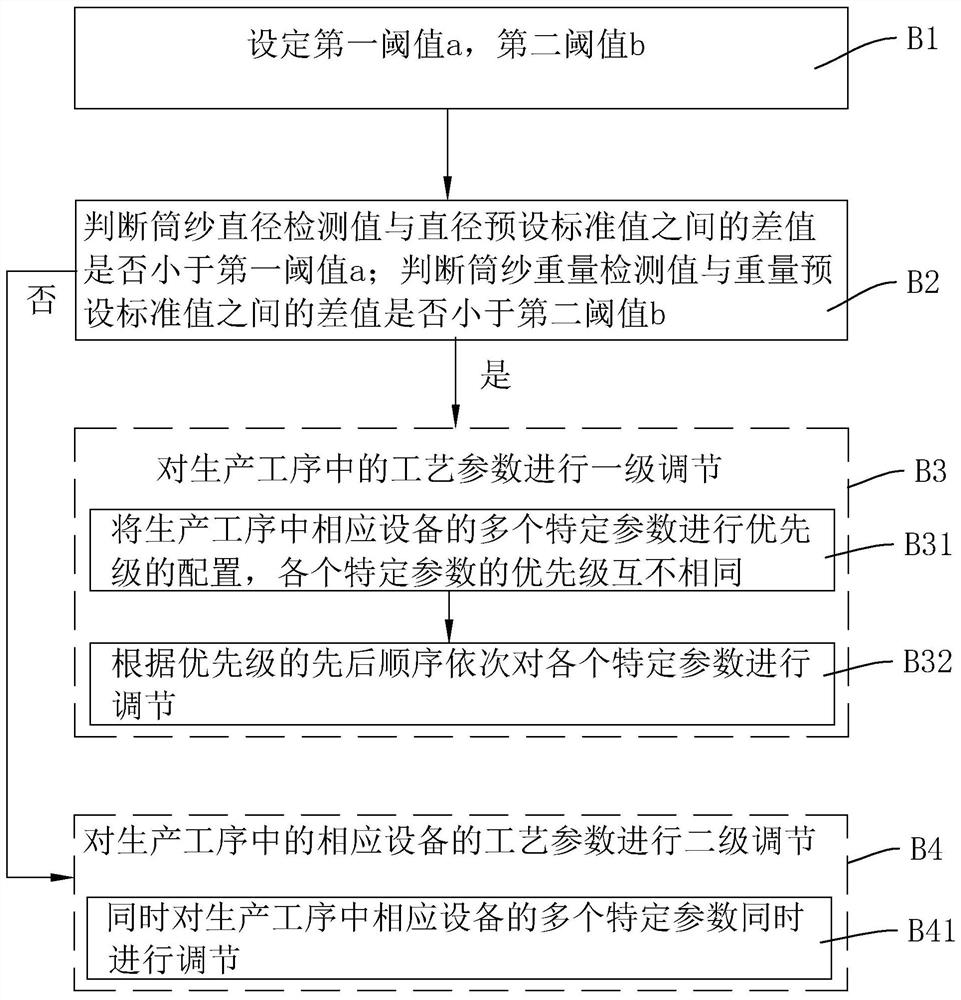

[0059] A fixed-length detection method for textile equipment, comprising a data detection method A and an adjustment method B.

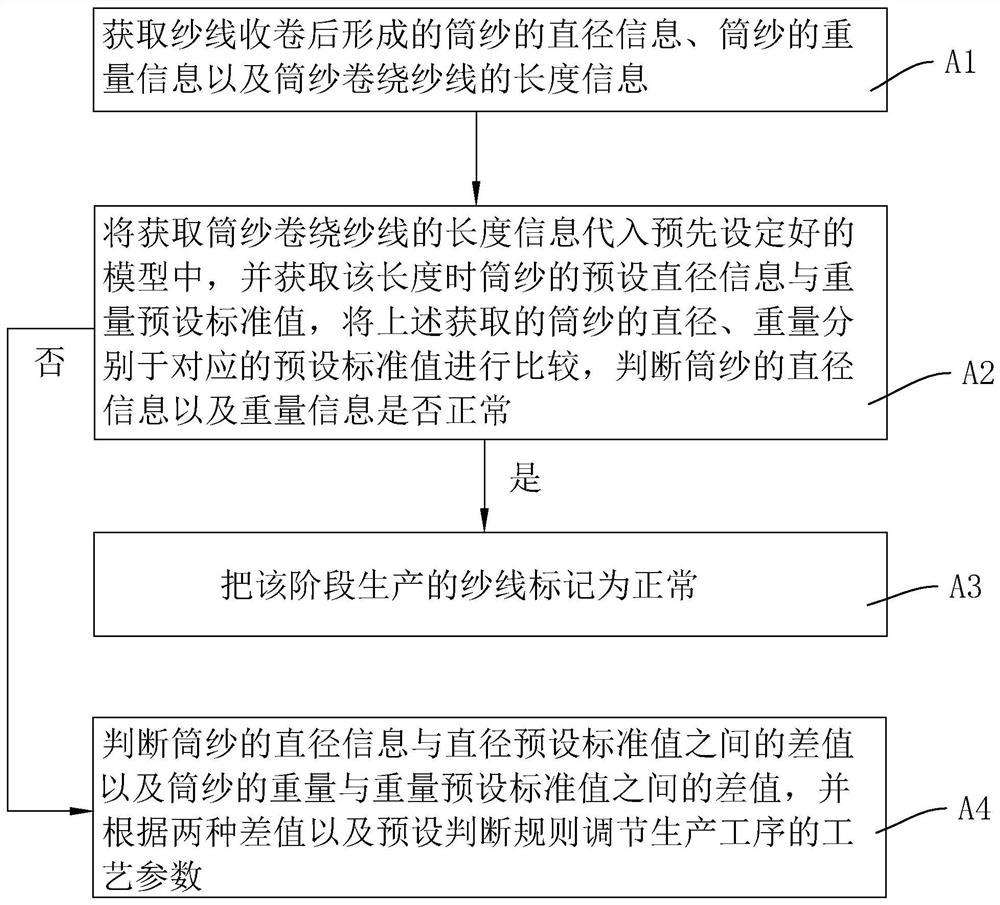

[0060] refer to figure 1 , data detection method A includes:

[0061] A1. Obtain the diameter information of the package yarn formed after the yarn is wound, the weight information of the package yarn and the length information of the package yarn wound yarn;

[0062] A2. Substitute the length information of the obtained package yarn winding yarn into the pre-set model, and obtain the preset standard value of the diameter and weight of the package yarn at this length, and use the package obtained in step A1 The diameter information and weight information of the yarn are compared with the corresponding preset standard values to determine whether the diameter information and weight information of the bobbin are normal. If it is judged to be normal, go to step A3; if it is judged to be abnormal, go to step A4 ;

[0063] Wherein, the preset standard...

Embodiment 2

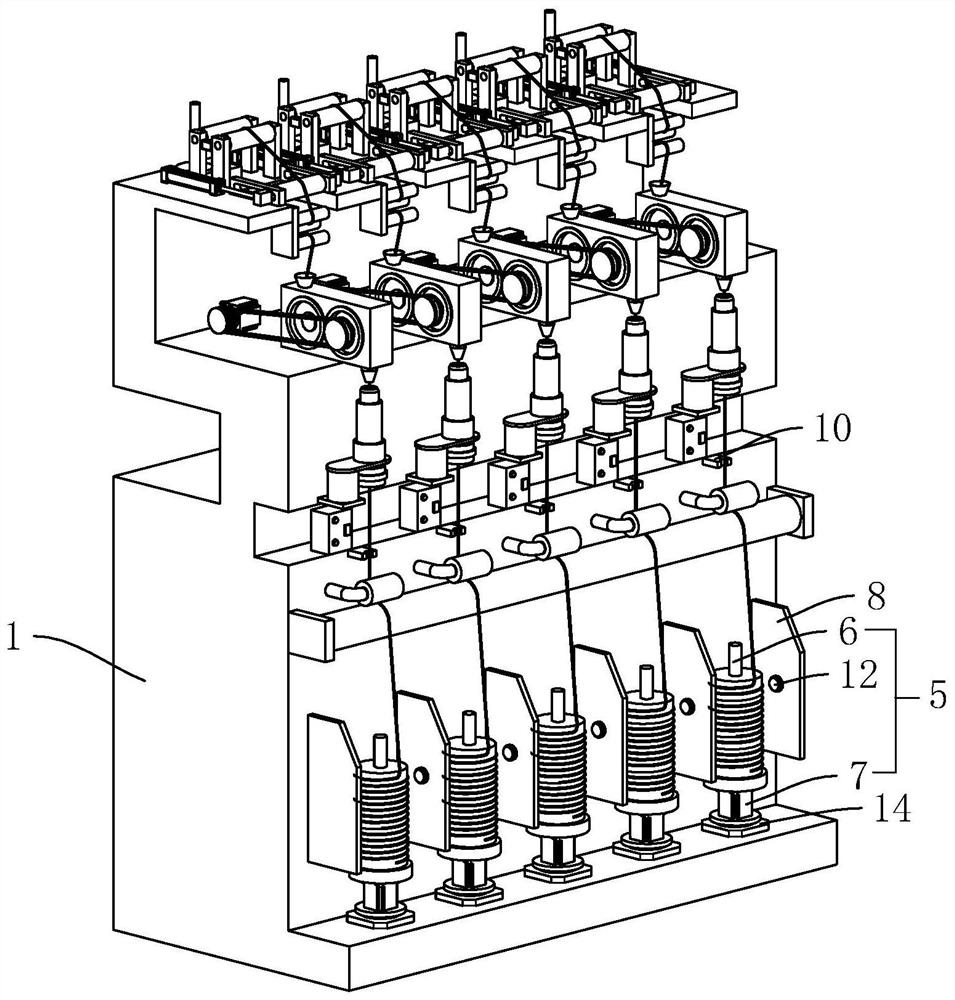

[0083] refer to image 3 and Figure 4 , is a fixed-length detection system for textile equipment, including a hair spraying machine body 1 , a model training module 2 , a controller 3 and a feedback module 4 . The model training module 2 is connected with the controller 3, and is used to collect the length of the winding yarn in the bobbin yarn formed by winding up 10,000 groups of yarns and the diameter and weight of the bobbin yarn under this length, establish a model, and obtain the bobbin The preset standard values of diameter and weight corresponding to different lengths of yarn winding.

[0084] refer to image 3 The body 1 of the hair spraying machine is provided with several winding devices 5, the winding device 5 includes a winding roller 6 for sheathing the yarn roll and a motor 7 for driving the winding roller 6 to rotate, two adjacent Baffles 8 are arranged between the winding devices 5 .

[0085] refer to image 3 and Figure 4 , the length detection modu...

Embodiment 3

[0094] A computer-readable storage medium, which stores a computer program that can be loaded by a processor and executes the fixed-length detection method as in Embodiment 1. The computer-readable storage medium includes: U disk, mobile hard disk, read-only memory, optical disc Various media that can store program codes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com