Flame retardant and anti-static fabric with protection coatings and preparation method of flame retardant and anti-static fabric

An anti-static fabric and protective coating technology, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, textile and other directions, can solve the problem of low comfort, anti-static and flame retardant effect of protective fabrics Poor skin performance and other problems, to achieve good flame retardant effect, easy to wash and dry, and good hygroscopicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

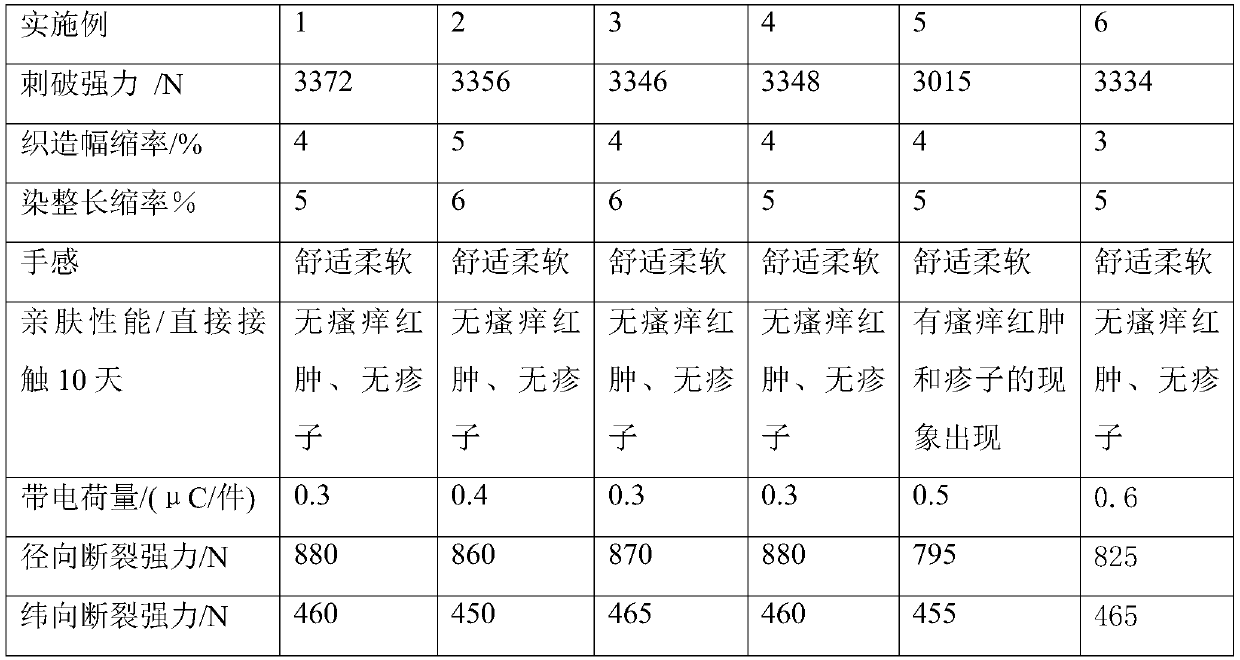

Examples

Embodiment 1

[0034] A flame-retardant antistatic fabric with a protective coating, the flame-retardant antistatic fabric with a protective coating is composed of an antistatic fabric and a flame-retardant protective coating coated on the outside of the antistatic fabric;

[0035] The flame retardant protective coating is composed of a protective coating A and a protective coating B, the protective coating A is evenly coated on the outer surface of the antistatic fabric, and the protective coating B is evenly coated on the The outer surface of the above protective coating A.

[0036]Specifically, the antistatic fabric is interwoven with warp and weft; the warp is blended with conductive fibers, high-strength vinylon fibers and ultra-high molecular weight polyethylene fibers, and the weft is made of polyester fibers and ultra-high molecular weight polyethylene Fiber blended. The blended yarn ratio of the warp is: conductive fiber: high-strength vinylon fiber: ultra-high molecular weight pol...

Embodiment 2

[0049] A flame-retardant antistatic fabric with a protective coating, the flame-retardant antistatic fabric with a protective coating is composed of an antistatic fabric and a flame-retardant protective coating coated on the outside of the antistatic fabric;

[0050] The flame retardant protective coating is composed of a protective coating A and a protective coating B, the protective coating A is evenly coated on the outer surface of the antistatic fabric, and the protective coating B is evenly coated on the The outer surface of the above protective coating A.

[0051] Specifically, the antistatic fabric is interwoven with warp and weft; the warp is blended with conductive fibers, high-strength vinylon fibers and ultra-high molecular weight polyethylene fibers, and the weft is made of polyester fibers and ultra-high molecular weight polyethylene Fiber blended. The blended yarn ratio of the warp is: conductive fiber: high-strength vinylon fiber: ultra-high molecular weight po...

Embodiment 3

[0064] A flame-retardant antistatic fabric with a protective coating, the flame-retardant antistatic fabric with a protective coating is composed of an antistatic fabric and a flame-retardant protective coating coated on the outside of the antistatic fabric;

[0065] The flame retardant protective coating is composed of a protective coating A and a protective coating B, the protective coating A is evenly coated on the outer surface of the antistatic fabric, and the protective coating B is evenly coated on the The outer surface of the above protective coating A.

[0066] Specifically, the antistatic fabric is interwoven with warp and weft; the warp is blended with conductive fibers, high-strength vinylon fibers and ultra-high molecular weight polyethylene fibers, and the weft is made of polyester fibers and ultra-high molecular weight polyethylene Fiber blended. The blended yarn ratio of the warp is: conductive fiber: high-strength vinylon fiber: ultra-high molecular weight po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com