Correction method for influence of cladding layer thickness on ultrasonic evaluation of cladding layer stress

A cladding layer and ultrasonic technology, which is applied in the field of ultrasonic nondestructive evaluation, can solve the problem of inability to realize online evaluation of cladding layer stress, and achieve the effect of realizing online evaluation and safe online evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

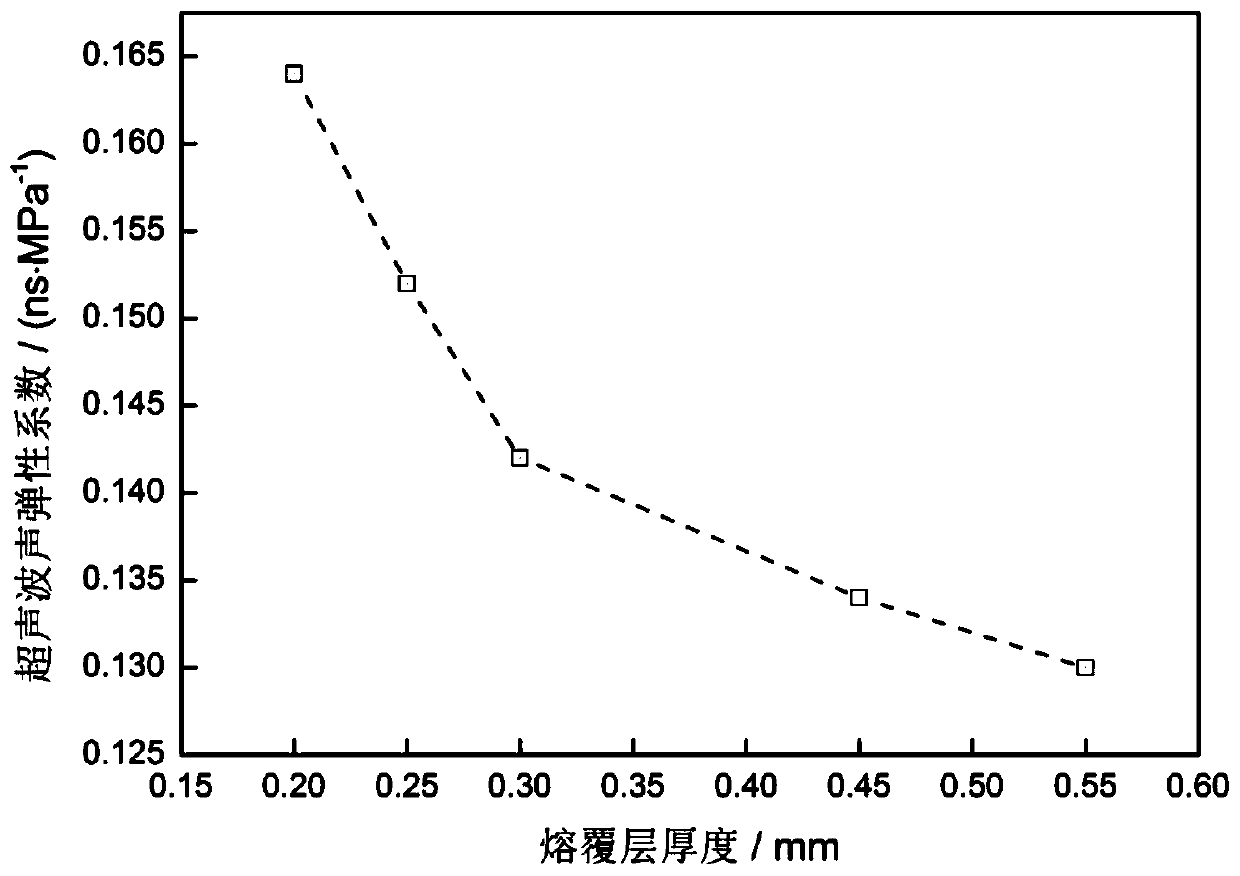

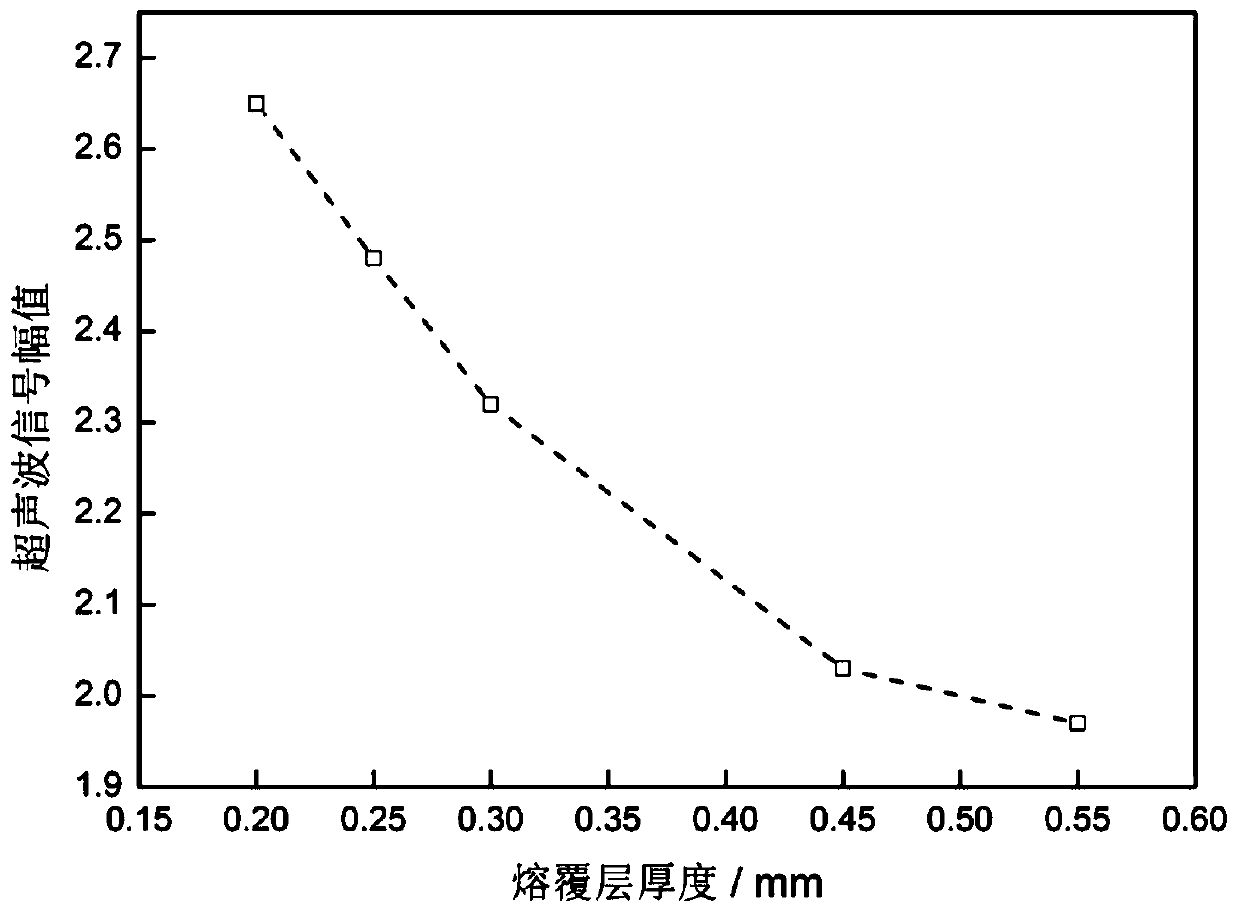

[0038] Taking the preparation of plasma cladding layer on the surface of low carbon steel as an example, the correction steps of cladding layer thickness affecting ultrasonic evaluation of cladding layer stress are described. The specific process is as follows:

[0039] Step 1: Select a Q235 steel plate with a thickness of 30mm as the substrate, and prepare a substrate sample. Determine the main process parameters of plasma cladding as follows: peak current 220A, base current 140A, frequency 60Hz, duty cycle 50%, cladding The speed is 0.2m / min, and the wire feeding speed is 3.0m / min. Five sets of cladding layers with different thicknesses are prepared on the surface of the substrate. After machining, the thicknesses of the plasma cladding layers are 0.20, 0.25, 0.30, 0.45 and 0.55mm Its surface roughness Ra is 1.0;

[0040]Step 2, according to GB / T2002-228 metal material room temperature tensile test method, prepare a plasma "substrate + cladding layer" cladding layer sample w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com