Pressure sensor system for compressor outlet pressure measurement

A pressure sensor and compressor technology, which is used in measurement devices, rapid changes in measurement, instruments, etc., can solve the problems of large delay in measurement systems, inability to compensate for algorithms, and low accuracy, and achieve the effect of meeting the needs of reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

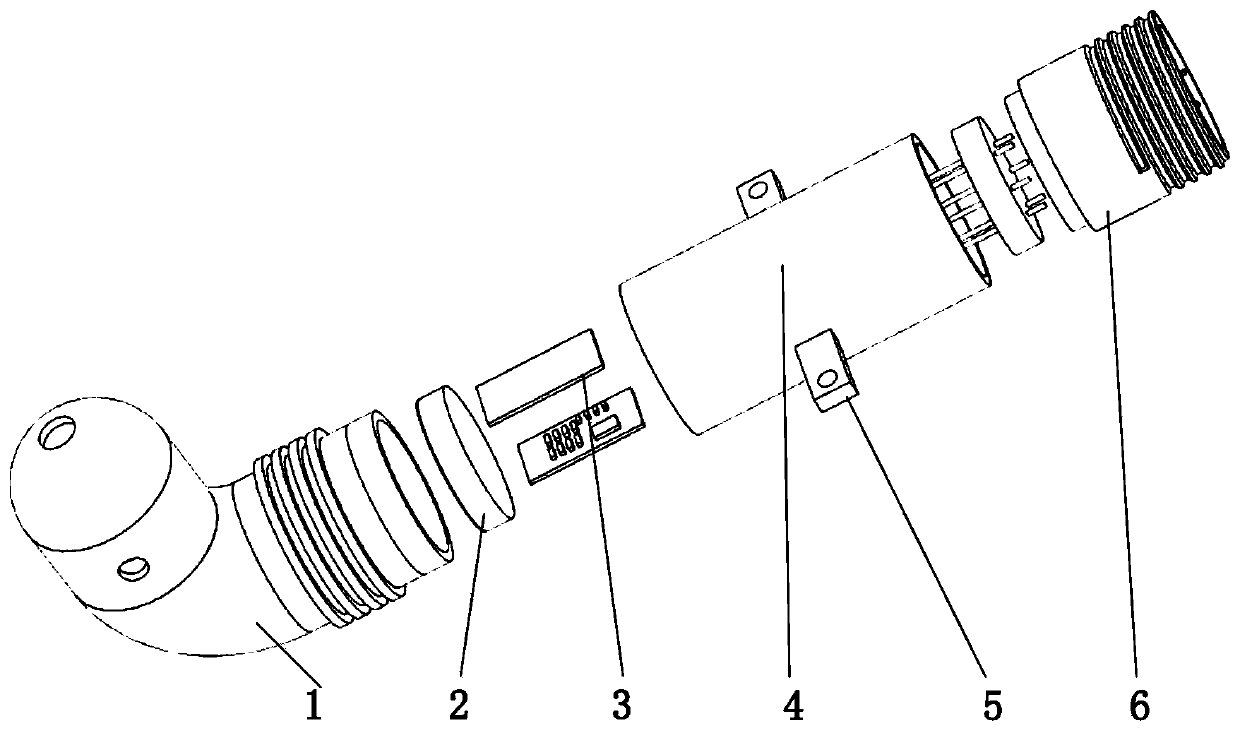

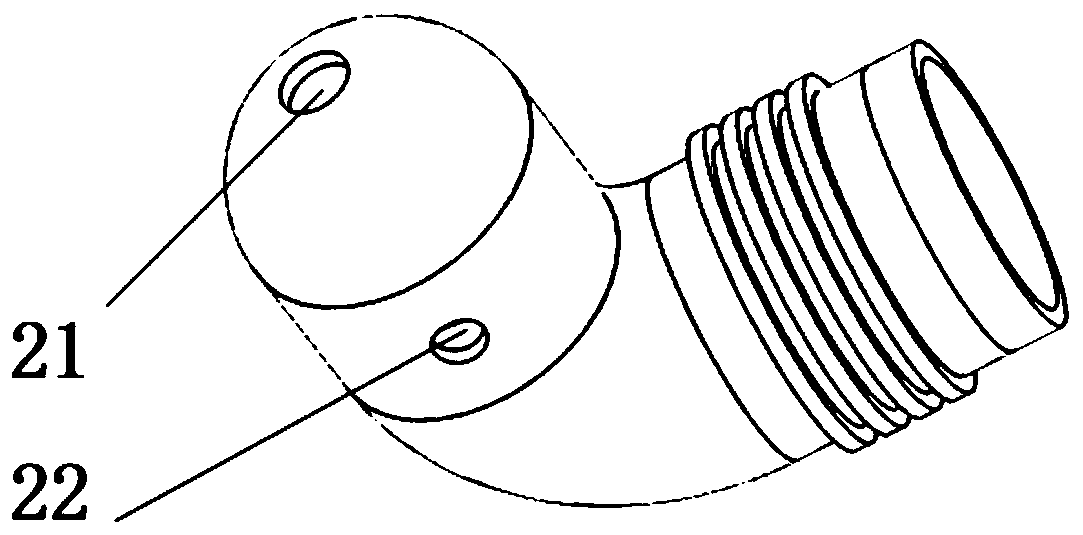

[0034] figure 1 It is the overall structure of the structural scheme of the pressure sensor (referred to as: dynamic pressure sensor) for measuring the outlet pressure of the compressor. figure 1 Among them are a short measuring tube 1, a pressure sensitive device 2, a signal processing module 3, a pressure housing 4, a fixing seat 5, and an output signal line connector 6. The dynamic pressure sensor of the present invention consists of short measuring tube 1 (including total pressure hole 21, static pressure hole 22 and annular ribs), pressure sensitive device 2, signal processing module 3, pressure housing 4, output signal Wire connector6. Wherein, the pressure sensitive device 2 and the signal processing module 3 are located in the pressure housing 4, and the housing is filled with protective insulating glue. The pressure sensitive dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com