Bonding type tensile rubber jacketed flexible cable

A tensile rubber sheath, flexible cable technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of twisted appearance, twisted cable sheath surface, affecting production operations, etc., and achieve a soft and round conductor structure. , the effect of excellent mechanical properties, excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution adopted by the present invention will be further described below in combination with schematic diagrams.

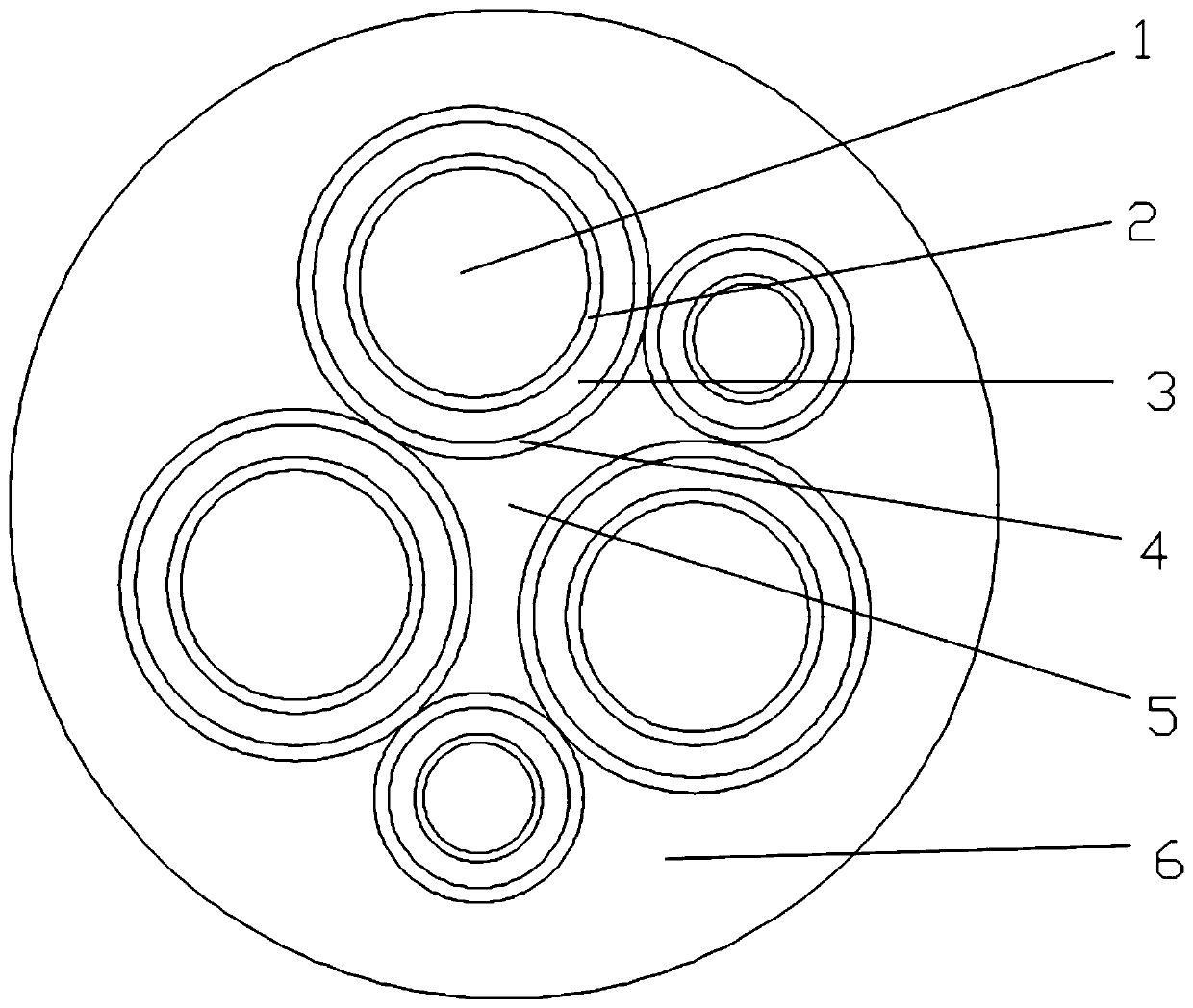

[0020] like figure 1 , a bonded tensile rubber-sheathed flexible cable, which includes a metal conductor 1, an isolation layer 2, an inner insulating layer 3, an outer insulating layer 4, a central tensile member 5, and a sheath layer 6. The isolation layer 2 is arranged outside the metal conductor 1 by wrapping or longitudinal wrapping, the inner insulating layer 3 and the outer insulating layer 4 are arranged outside the insulating layer 2 by double-layer co-extrusion, and the cable core is surrounded by the power core and the ground core. The puller 5 is twisted into a cable, and the sheath layer 6 is arranged outside the cable core by extrusion. The central tensile member is made of high-strength natural styrene-butadiene rubber extruded from a steel wire rope, and the diameter of the steel wire rope is 1.0mm to 3.0mm.

[0021] Metal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com