Flexible electromagnetic scattering regulation and control structure and manufacturing method thereof

An electromagnetic scattering and manufacturing method technology, applied in electrical components, antennas and other directions, can solve the problems of inability to large-scale production and application, complex structure, and high power consumption, and achieve breakthroughs in limited process size, low manufacturing difficulty, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

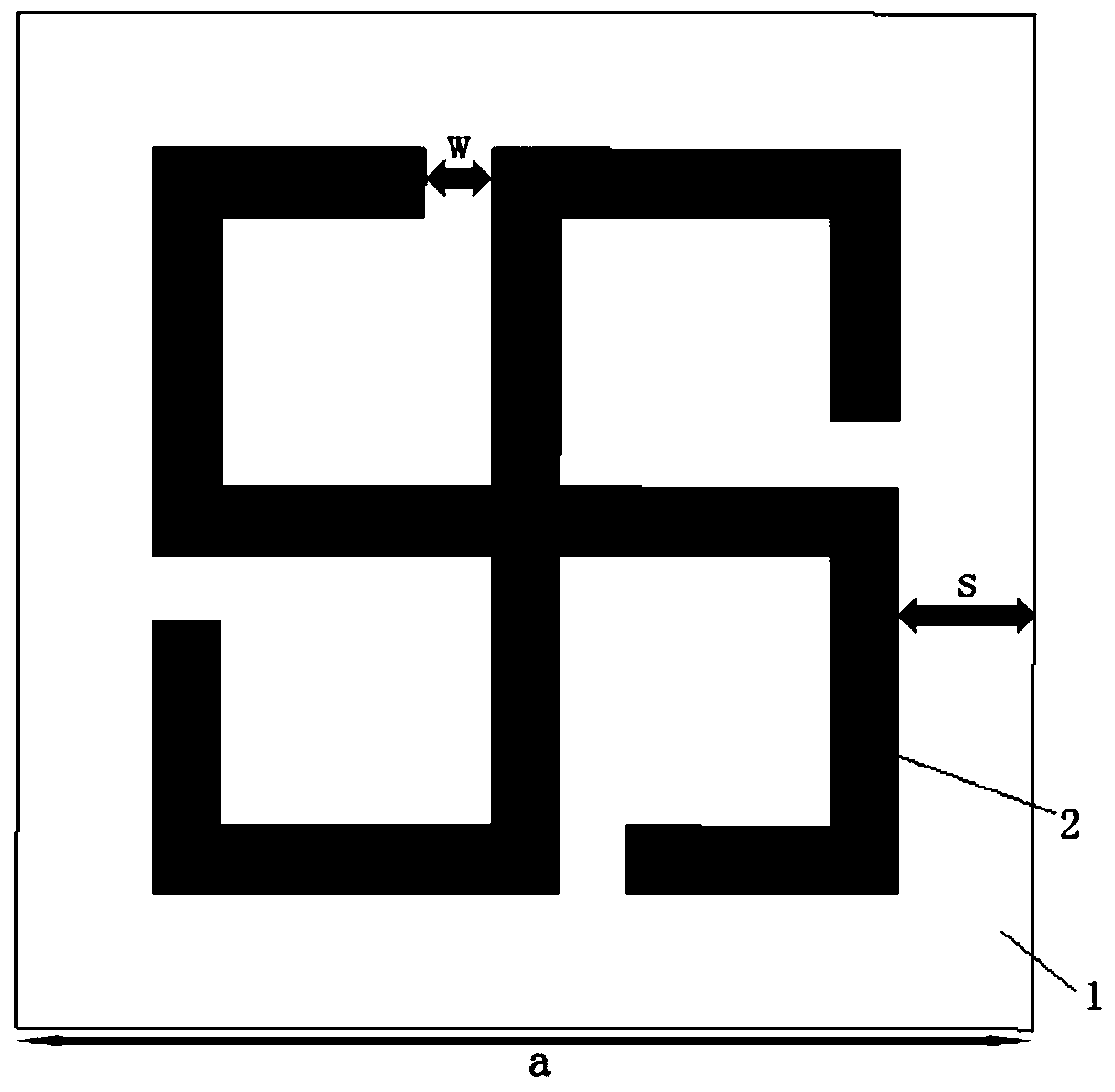

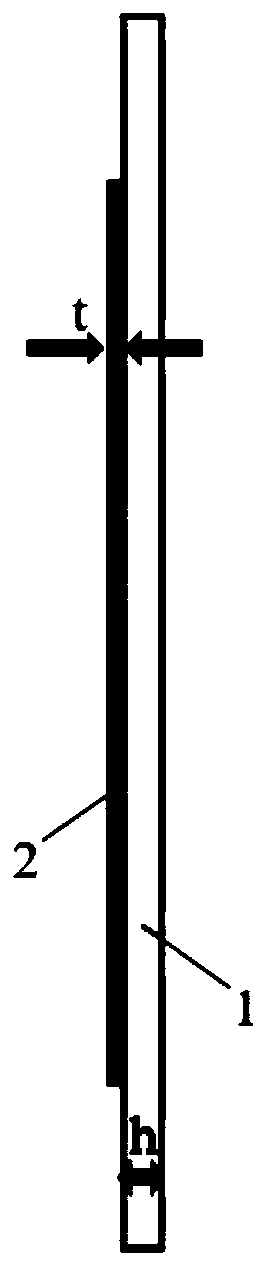

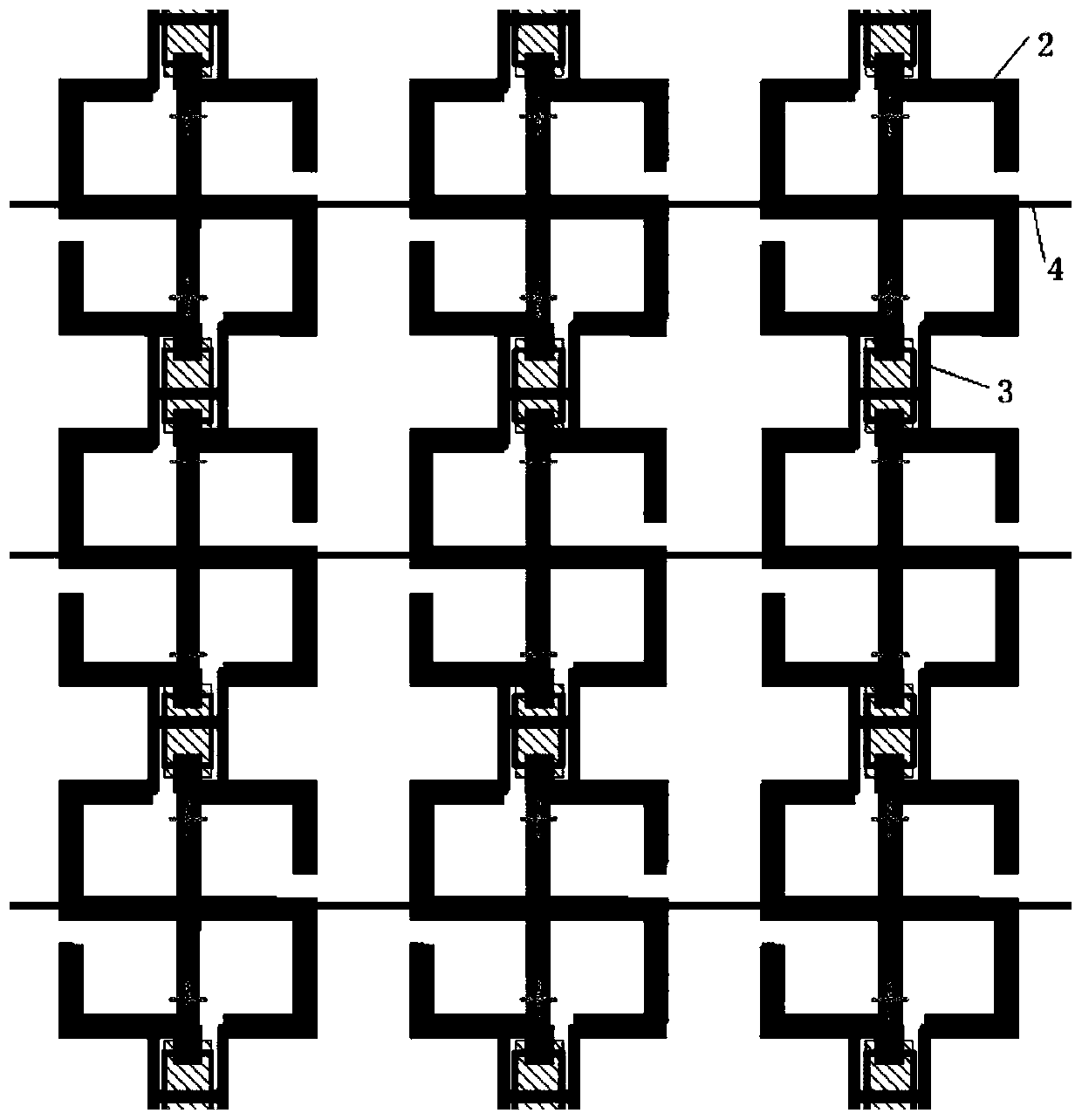

[0043] see Figure 1 to Figure 3 In this embodiment, on the basis of the simple cross structure and the Nazi cross structure, a centrally connected square spiral unit is designed as the conductive unit 2 by bending the metal arms at both ends. According to the inference of Professor Ben A. Munk, the conductive unit is a centrosymmetric structure, and the mode interaction zero point is relatively high, so it has good angle and polarization stability. In addition, the conductive unit size of the flexible electromagnetic scattering control structure is small, and the array element spacing is smaller. According to the grating lobe formula, reducing the conductive unit spacing can increase the frequency of grating lobes, and the angle and polarization stability are higher.

[0044] The detailed dimensions of the conductive unit structure are shown in Table 1 below, where w represents the metal line width, s represents the distance from the metal to the cell boundary, a represents t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com