Three-stage condensation system of VOCs purification treatment device

A purification treatment and condensation system technology, applied in gas treatment, steam condensation, multi-effect/separation condensation, etc., can solve environmental pollution and other problems, and achieve the effect of improving quality and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

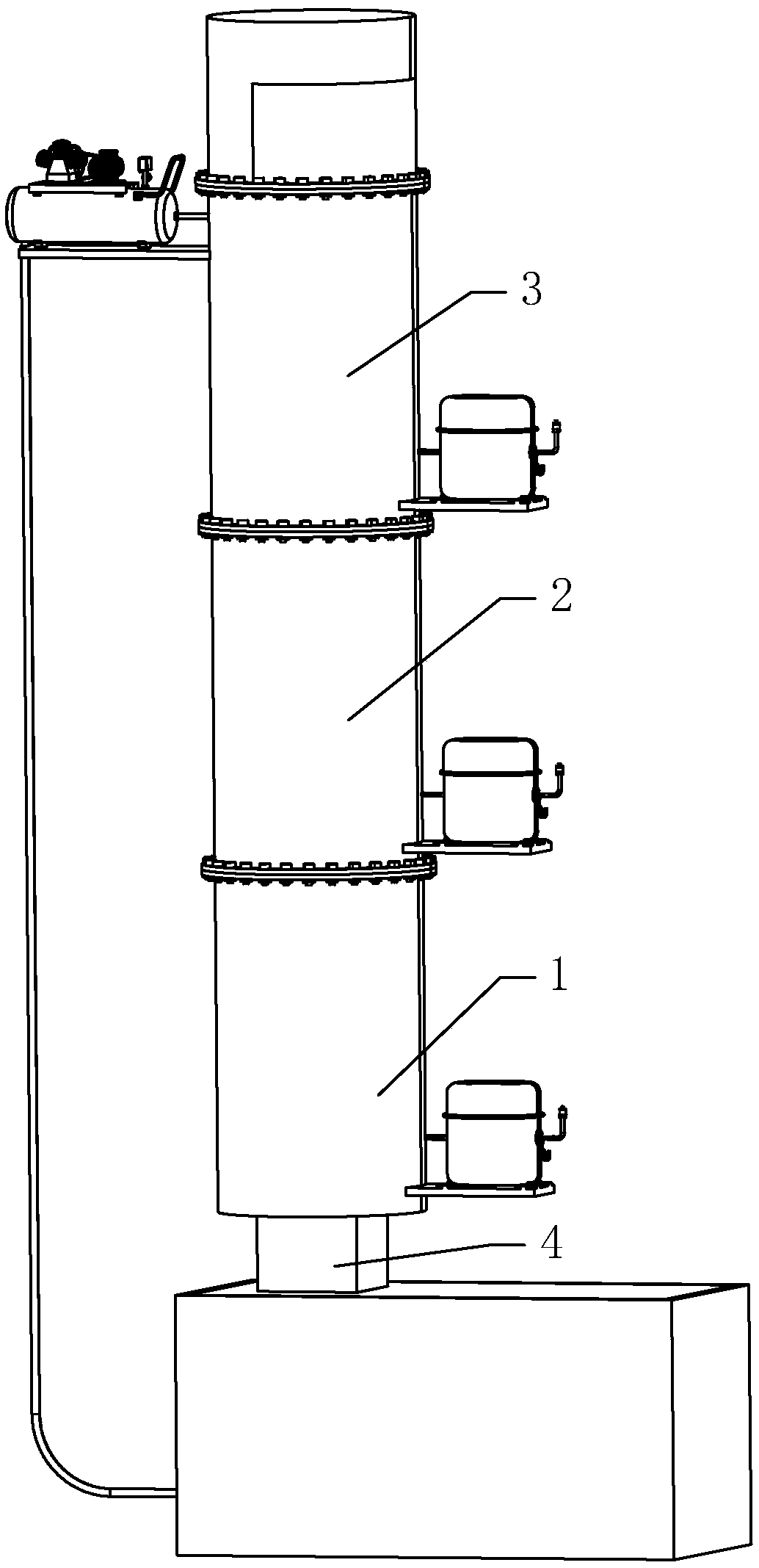

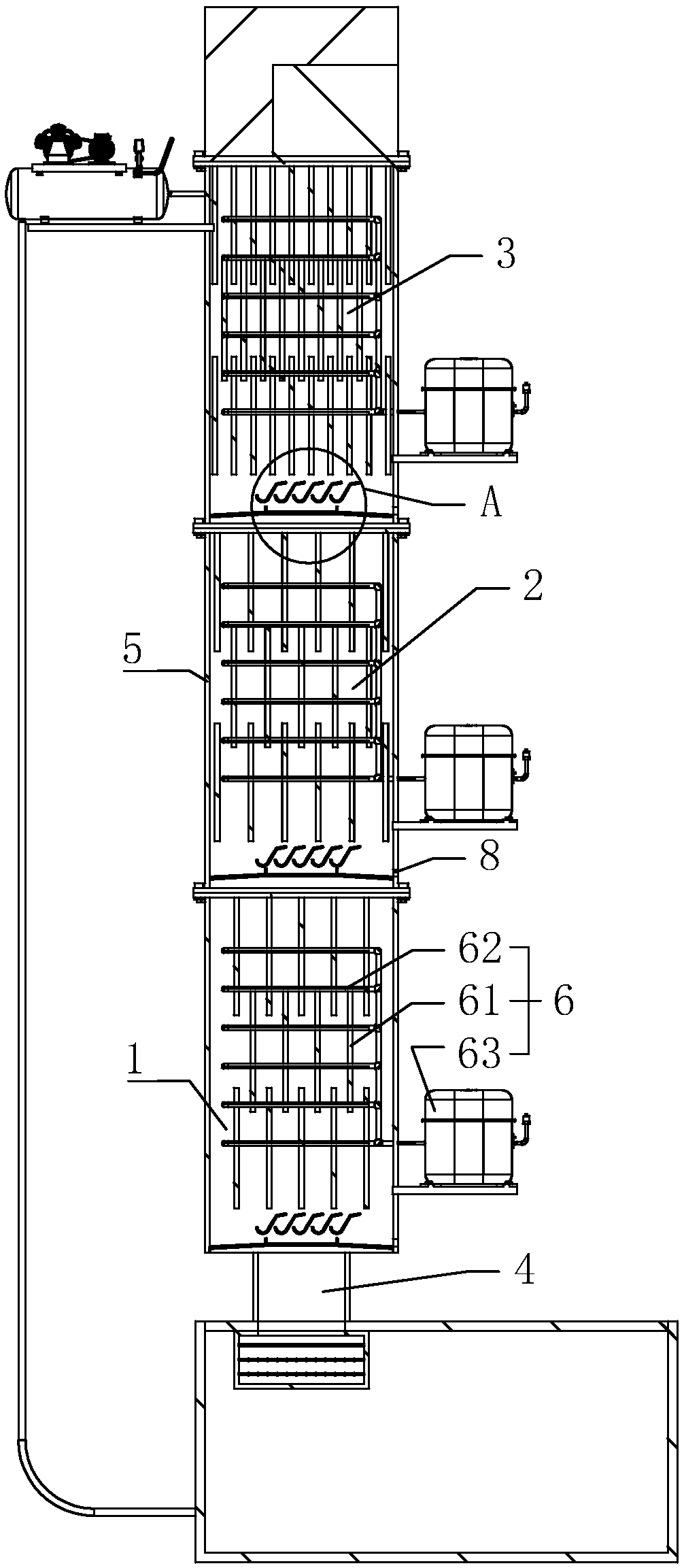

[0039] Embodiment one: a kind of three-stage condensing system of VOCs purification treatment device, such as figure 1 with 2 As shown, it includes a primary primary cooling system 1, a secondary intercooling system 2 arranged above and connected to the primary primary cooling system 1, a tertiary deep cooling system 3 arranged above and connected to the secondary intercooling system 2, and a The primary primary cooling system 1 , the secondary intercooling system 2 and the tertiary cryogenic system 3 all include a thermal insulation bucket 5 and a refrigeration assembly 6 connected to the thermal insulation bucket 5 .

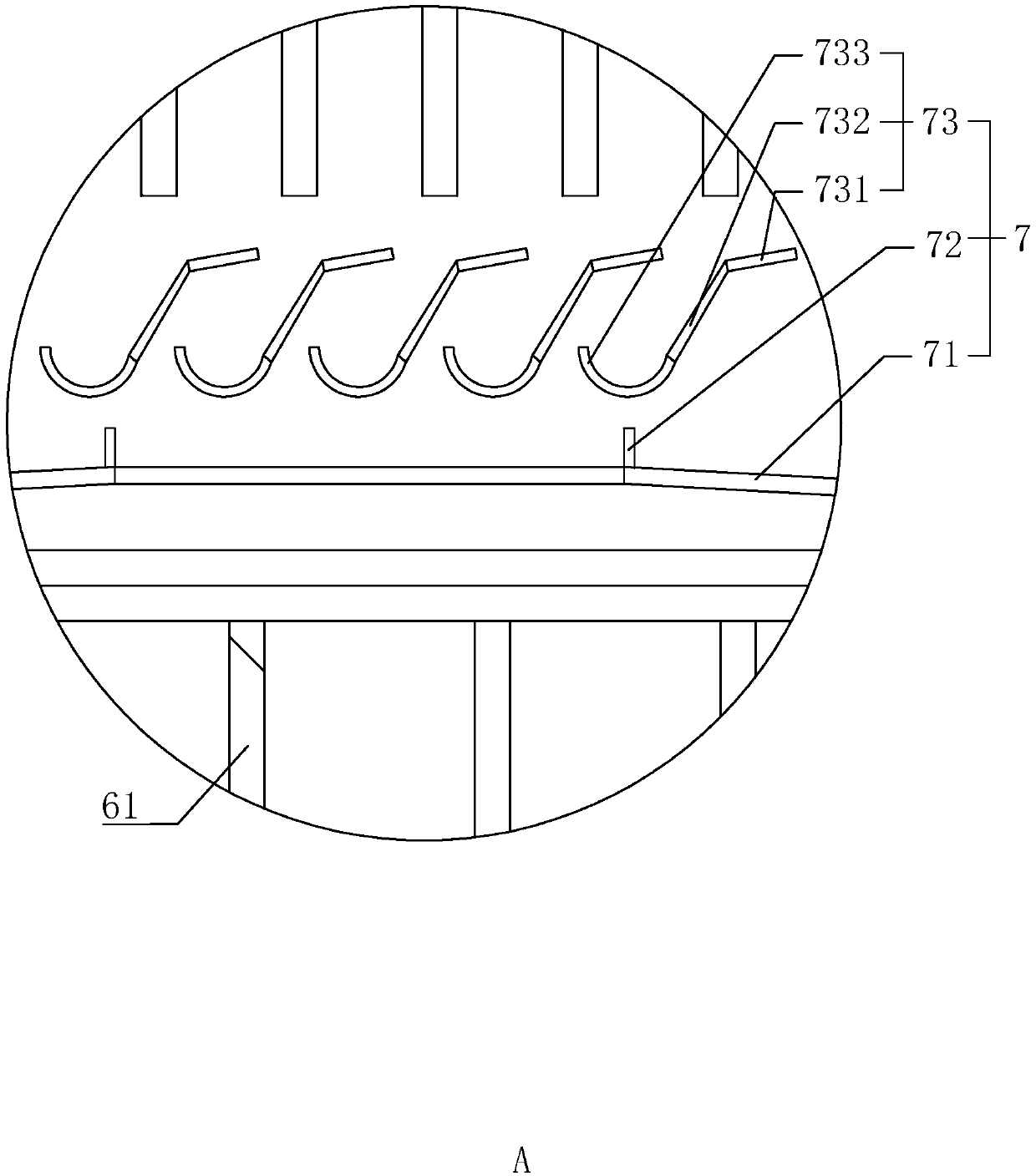

[0040] Such as figure 2 As shown, the first-level primary cooling system 1, the second-level intercooling system 2 and the third-level cryogenic system 3 all include a heat preservation barrel 5 and a refrigeration assembly 6 connected to the heat preservation barrel 5. The refrigeration assembly 6 includes a Several refrigerating sheets 61 in the 5, the co...

Embodiment 2

[0050] Embodiment 2: The difference from Embodiment 1 is that, as Figure 5 with 6 As shown, the non-return assembly 73 includes a non-return cap 734 arranged above the collection ring plate 71, a support rod 735 connecting the non-return cap 734 and the collection ring plate 71, the non-return cap 734 covers the opening of the collection ring plate 71, and extends The side above the collecting ring plate 71 is located on the side of the baffle plate 72 away from the center of the heat preservation bucket 5 . The condensed chemical substances fall onto the non-return cap 734, and slide down to the collection ring plate 71 along the non-return cap 734, effectively realizing that the condensed chemical substances fall into the condensing system of the lower stage, and the non-return cap 734 also does not affect the flow of non-condensable gas in VOCs to the upstream condensation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com