Rotary steering command downloading method based on motor variable frequency control

A frequency conversion control and rotary steerable technology, which is applied in the field of oil drilling, can solve the problems of cumbersome operation, high bit error rate, and low precision, and achieve the effect of effective verification and downloading, and improving the accuracy of downloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

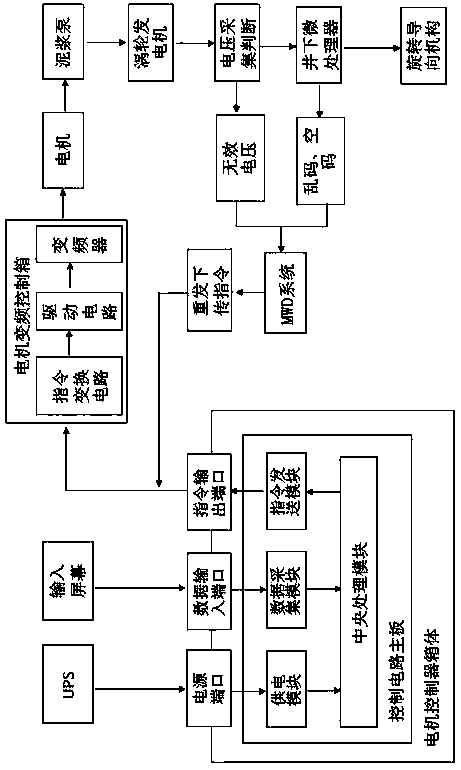

[0039] see figure 1 , a method for transmitting rotation-steering commands based on motor frequency conversion control, comprising the following steps:

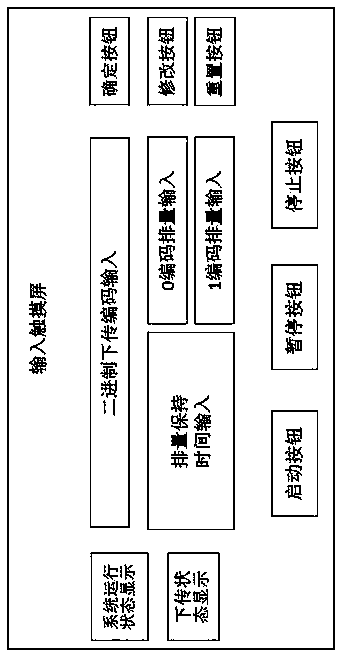

[0040] a. The motor controller box of the rotation-guided command downlink system receives the input parameters input to the touch screen, processes the input data and outputs the motor frequency conversion control command;

[0041] b. The motor frequency conversion control box performs command conversion and control signal amplification, and outputs frequency conversion signals;

[0042] c. The motor receives the frequency conversion signal for speed control, adjusts the pump stroke of the mud pump through the motor speed to form a corresponding displacement, and the mud drives the downhole turbine generator to form a turbine voltage;

[0043] d. The invalid voltage is judged by the voltage acquisition judger, and the downhole microprocessor processes the voltage signal and judges the garbled code invalid download command a...

Embodiment 2

[0047] see figure 1 and figure 2 , a method for transmitting rotation-steering commands based on motor frequency conversion control, comprising the following steps:

[0048] a. The motor controller box of the rotation-guided command downlink system receives the input parameters input to the touch screen, processes the input data and outputs the motor frequency conversion control command;

[0049] b. The motor frequency conversion control box performs command conversion and control signal amplification, and outputs frequency conversion signals;

[0050] c. The motor receives the frequency conversion signal for speed control, adjusts the pump stroke of the mud pump through the motor speed to form a corresponding displacement, and the mud drives the downhole turbine generator to form a turbine voltage;

[0051] d. The invalid voltage is judged by the voltage acquisition judger, and the downhole microprocessor processes the voltage signal and judges the garbled code invalid dow...

Embodiment 3

[0057] see figure 1 and figure 2 , a method for transmitting rotation-steering commands based on motor frequency conversion control, comprising the following steps:

[0058] a. The motor controller box of the rotation-guided command downlink system receives the input parameters input to the touch screen, processes the input data and outputs the motor frequency conversion control command;

[0059] b. The motor frequency conversion control box performs command conversion and control signal amplification, and outputs frequency conversion signals;

[0060] c. The motor receives the frequency conversion signal for speed control, adjusts the pump stroke of the mud pump through the motor speed to form a corresponding displacement, and the mud drives the downhole turbine generator to form a turbine voltage;

[0061] d. The invalid voltage is judged by the voltage acquisition judger, and the downhole microprocessor processes the voltage signal and judges the garbled code invalid dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com