A boiler furnace pressure control method and system based on fcb process

A pressure control and control system technology, applied in the direction of control system, combustion control, combustion method, etc., can solve the problems of large overshoot, long adjustment cycle, FCB failure of coal-fired units, etc., to reduce the adjustment cycle and solve the adjustment cycle too long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0063] The above is the first embodiment of a boiler furnace pressure control method based on the FCB process provided by the embodiment of the present application, and the following is the second embodiment of a boiler furnace pressure control method based on the FCB process provided by the embodiment of the present application, The second embodiment further illustrates the boiler furnace pressure control method based on the FCB process.

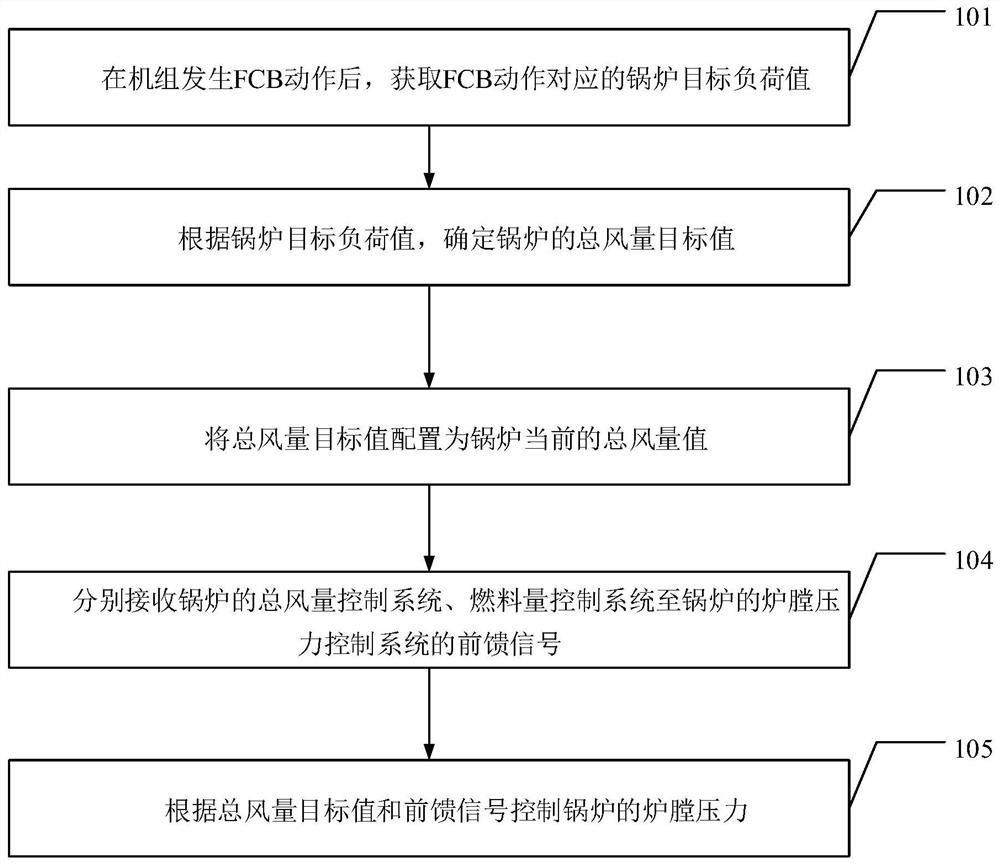

[0064] see Figure 4 , Figure 4 Another schematic flow chart of the boiler furnace pressure control method based on the FCB process provided in the embodiment of the present application, including:

[0065] Step 201, after the FCB action of the unit, obtain the boiler target load value corresponding to the FCB action.

[0066] Step 201 in this embodiment is the same as step 101 in the first embodiment, for details, please refer to step 101 in the first embodiment, which will not be repeated here.

[0067] Step 202: Determine the total a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com