Method for in-situ determination of deep water reservoir sediment denitrification and anaerobic ammonia oxidation rates

An anaerobic ammonia oxidation and sediment technology, applied in environmental monitoring, to the field of water environment, can solve the problems of interference experiment accuracy, sediment and overlying water disturbance, etc., to achieve accurate and reliable test results, reduce interference, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

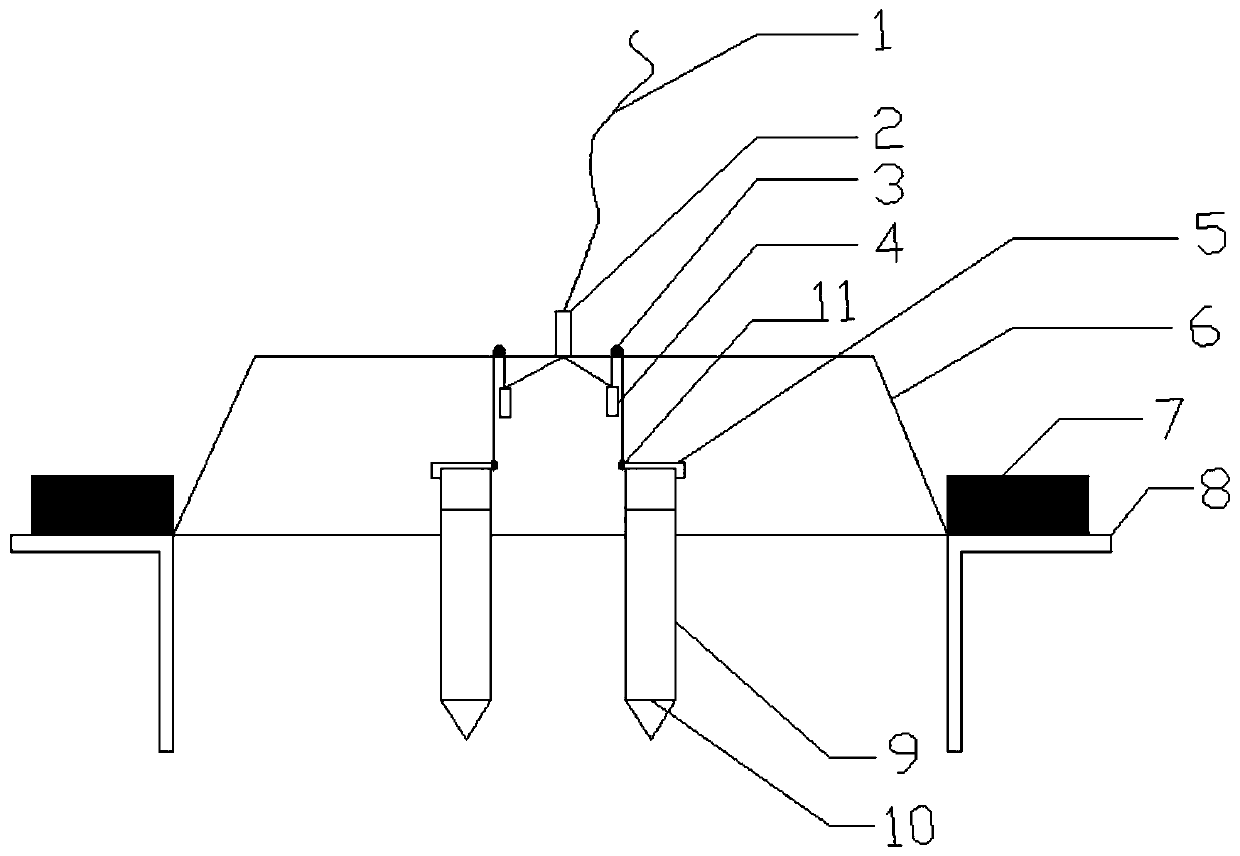

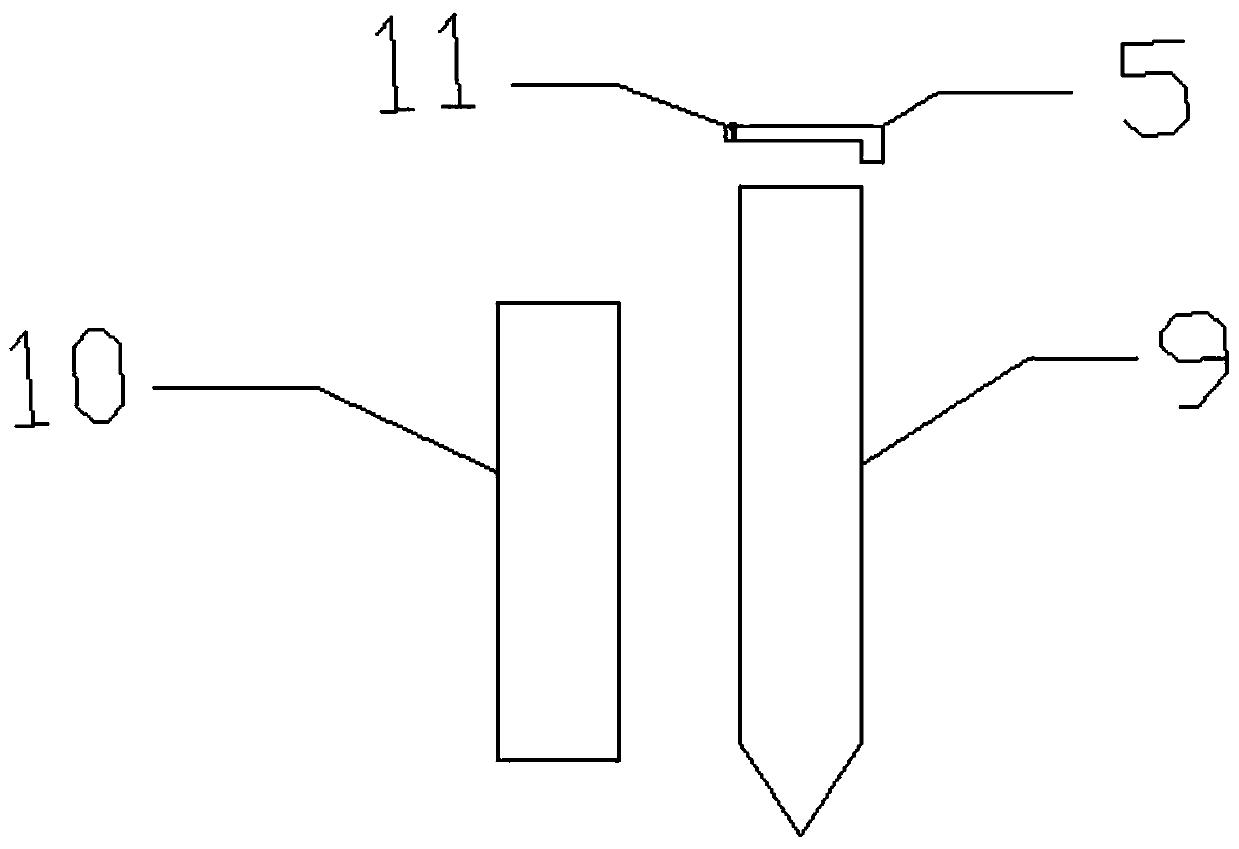

[0034] An in-situ method for determining the denitrification and anammox rate of deep-water reservoir sediments, mainly using a sediment in-situ replacement device, such as figure 1 As shown, the schematic diagram of the disassembly of the culture tube and the culture tube protective cover is shown in figure 2 shown. A sediment in-situ replacement device, including a steel wire rope 1, a weight starter 2, a roller 3, a weight 4, a rotating cover 5, a bracket 6, a counterweight 7, a sinking plate 8, a culture tube protective cover 9, a culture tube Tube 10, swivel cap latch 11. The bracket 6, the sinking plate 8 and the culture tube protective cover 9 are welded together to form the main body of the device. On the anti-sinking plate 8, a counterweight 7 can be added according to the water depth to ensure that the device is in good contact with the sediment; the roller 3 is located on the support 6, one end of the roller 3 is connected with the weight 4 through a rope, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com