Weld beading size measuring method for two-dimensional image of small-diameter tube weld joint root

A two-dimensional image technology of the root of the weld, which is applied in the field of measurement of the size of the two-dimensional image of the weld root of the small-diameter pipe weld, can solve the problems of poor reliability, interference, and low precision, so as to ensure safe operation, avoid low detection speed, Avoid the effect that the weld defect area cannot be accurately and completely segmented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

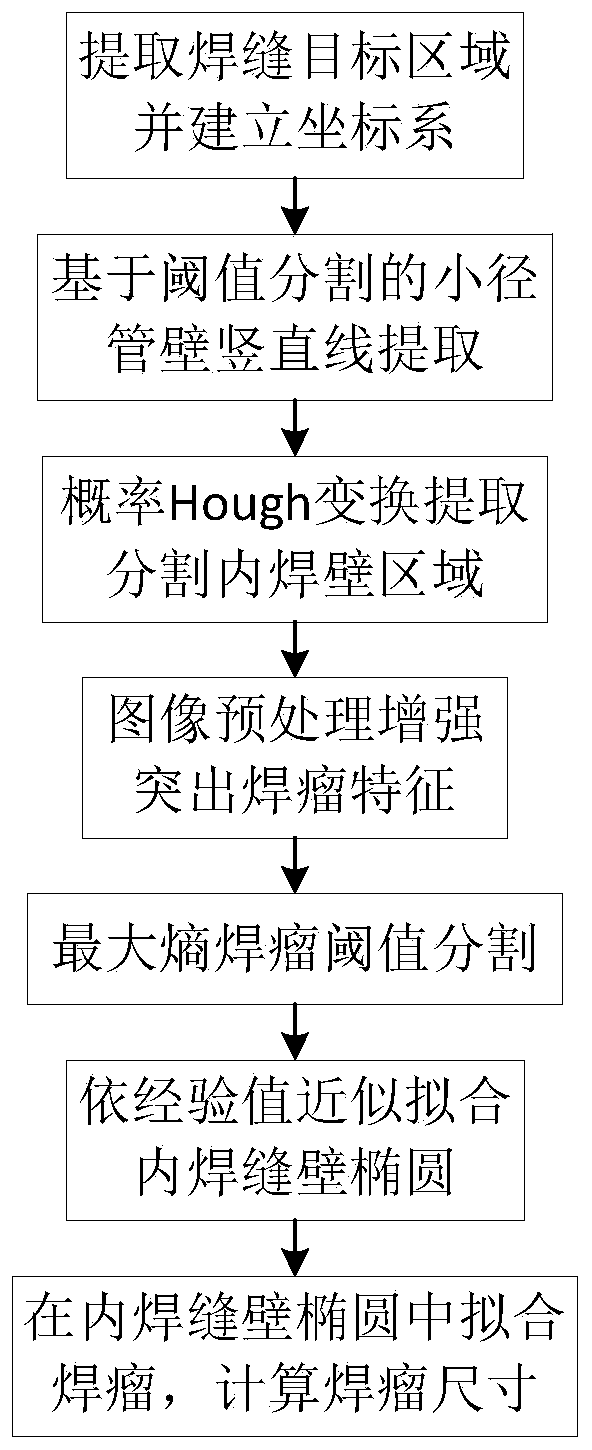

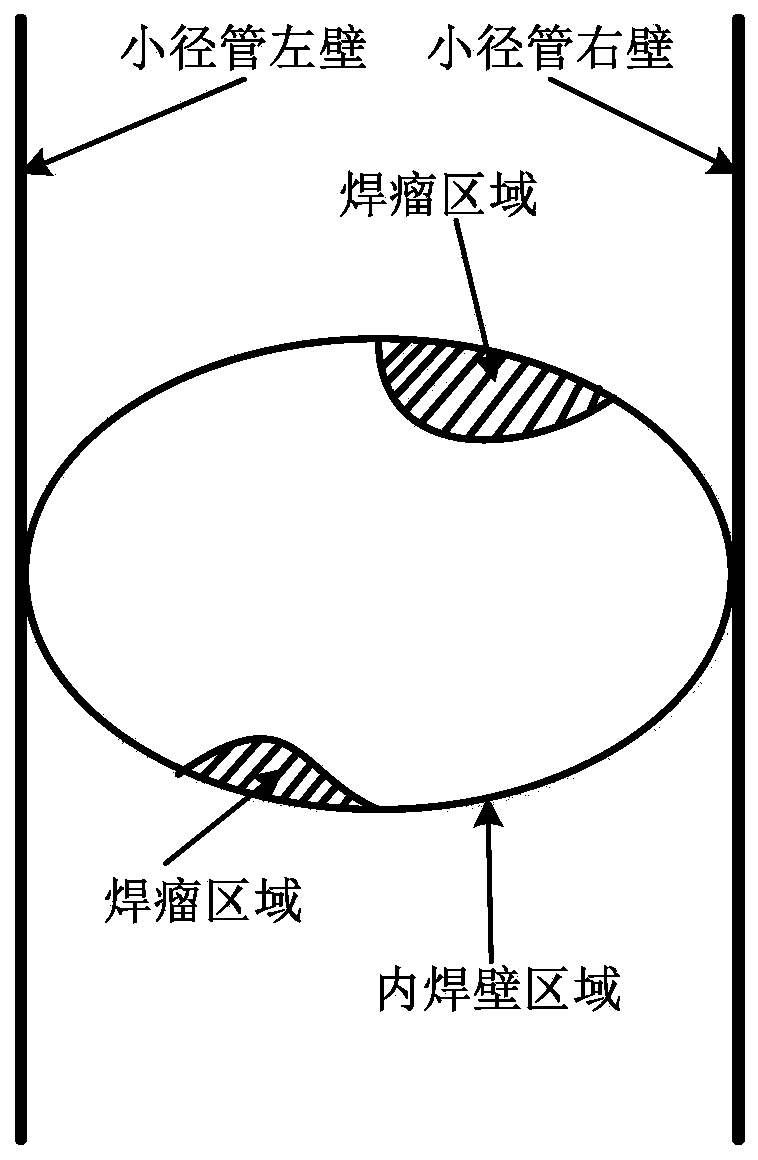

[0068] Such as figure 1 As shown, the present invention has designed a kind of small-diameter pipe weld root two-dimensional image weld bead size measurement method, and this method specifically comprises the following steps:

[0069] Step S1: According to the fact that the actual weld area in the image is located in the middle of the small-diameter pipe, reserve the middle position as the target area A, and take the upper left corner of the target area A as the origin to establish the image pixel coordinate system i-j, where i and j are respectively The horizontal and vertical axes of the coordinate system.

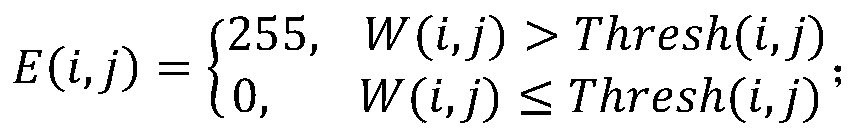

[0070] Step S2: Extract the vertical line of the small-diameter pipe wall by using the adaptive thresholding operation, including:

[0071] S2.1: Use the weighted average method to convert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com