Polymer filling bone material and preparation method thereof

A technology of polymer materials and bone materials, which is applied in the fields of medical formula, medical science, tissue regeneration, etc., can solve problems such as complicated operation, and achieve the effect of simple operation, low technical content, and increased elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

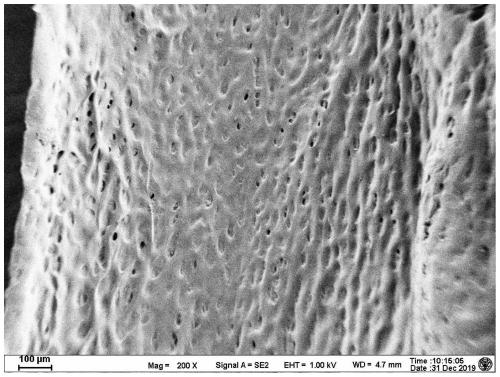

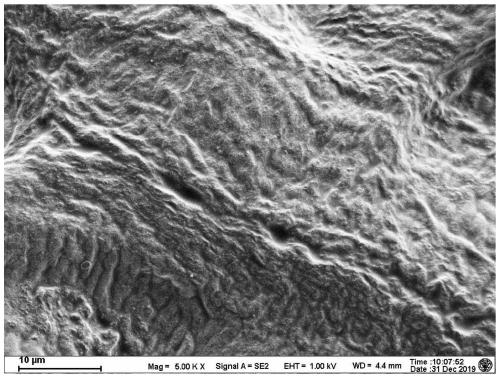

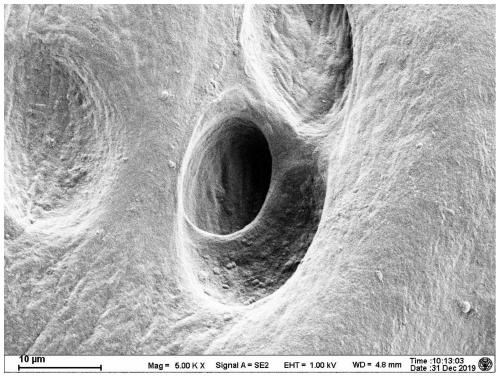

Image

Examples

Embodiment 1

[0017] The bone material was soaked in 50% ethanol prepared with pure water for 5 h, then dried naturally, and then the PDMS polydimethylsilane A and B liquids were fully mixed at a speed of 200 rpm for 10 minutes with a ratio of 1:1. min mixing, soak the dried bone material in the PDMS polydimethylsilane prepared and mixed, after blending, put it in the temperature environment of 37 ℃ for full penetration for 30 min, and then in the environment of 68 ℃ React for 6 h, and finally bake at 120 °C for 10 min, take out the baked bone material, let it stand at room temperature for 15 min, remove the PDMS polydimethylsilane covering the surface, and soak the bone material with 50% alcohol. Experiment failed.

Embodiment 2

[0019] Soak the bone material in 20% ethanol prepared with pure water for 5 h, then let it dry naturally, then fully mix the PDMS polydimethylsilane A and B liquid at a speed of 100 rpm with a ratio of 3:1 for 5 h Min mixing, soak the dried bone material in the prepared and mixed PDMS polydimethylsilane, after blending, put it in a temperature environment of 30 ℃ to fully infiltrate and cross-link for 60 minutes, and then react in an environment of 30 ℃ 8 h, and finally baked at 120 °C for 10 min, took out the baked bone material, let it stand at room temperature for 10 min, removed the PDMS polydimethylsilane covering the surface, and soaked the bone material with 25% ethanol. The experiment was successful.

Embodiment 3

[0021] The bone material was soaked in 50% ethanol prepared with pure water for 5 h, then dried naturally, and then the PDMS polydimethylsilane A and B liquids were fully mixed at a speed of 200 rpm for 10 minutes with a ratio of 5:1. min mixing, soak the dried bone material in the PDMS polydimethylsilane prepared and mixed, after blending, put it in the temperature environment of 37 ℃ for full penetration for 30 min, and then in the environment of 68 ℃ React for 6 h, and finally bake at 120 °C for 10 min, take out the baked bone material, let it stand at room temperature for 15 min, remove the PDMS polydimethylsilane covering the surface, and soak the bone material with 50% ethanol. The experiment was successful.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com