Automatic machining method and device for small PVC short pipes

A technology of processing device and processing method, which is applied in the directions of grinding drive device, metal processing, metal processing equipment, etc., can solve the problems of worker injury, low efficiency of manual processing, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

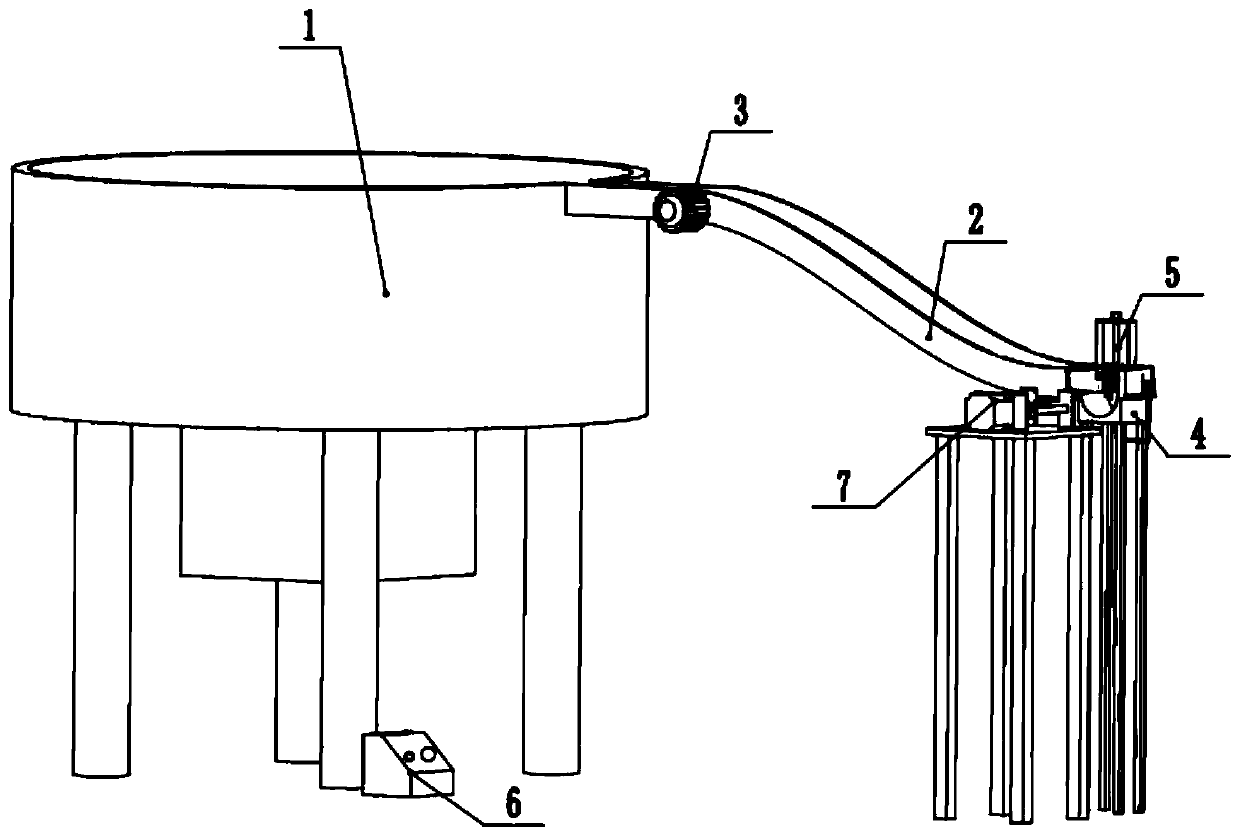

[0022] An automatic processing device for small PVC short pipes, which is composed of a vibration plate 1, a discharge track 2, a material counting mechanism 3, a processing base 4, a positioning hole processing mechanism 5, and a controller 6. The discharge track 2 is installed on the vibration plate 1, the counting mechanism 3 is installed on the discharge track 2, the processing base 4 is installed at the end of the discharge track 2, the positioning hole processing mechanism 5 is installed on the processing base 4, and the controller 6 is installed under the vibrating plate 1 .

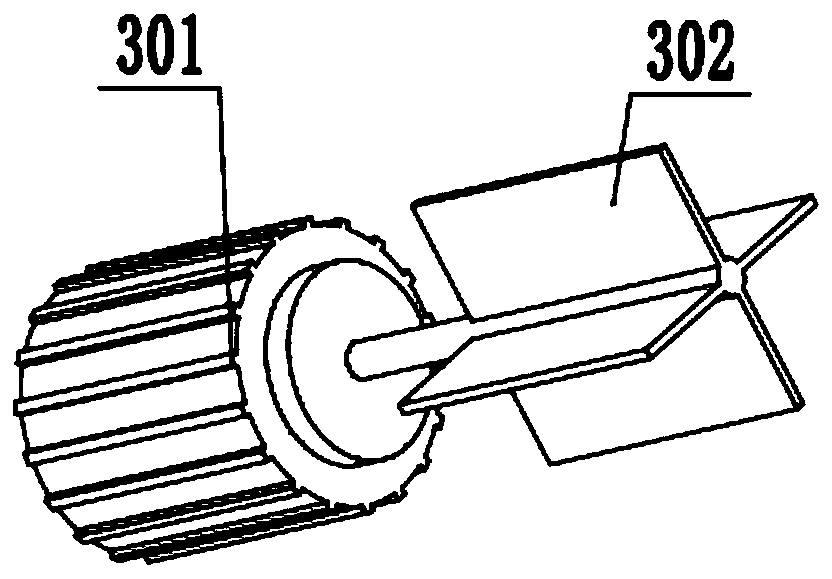

[0023] Described counting material mechanism 3 is rented by decelerating DC motor 301, counting material fan wheel 302, and decelerating DC motor 301 is installed on the discharge track, and drives counting material fan wheel 302 to rotate.

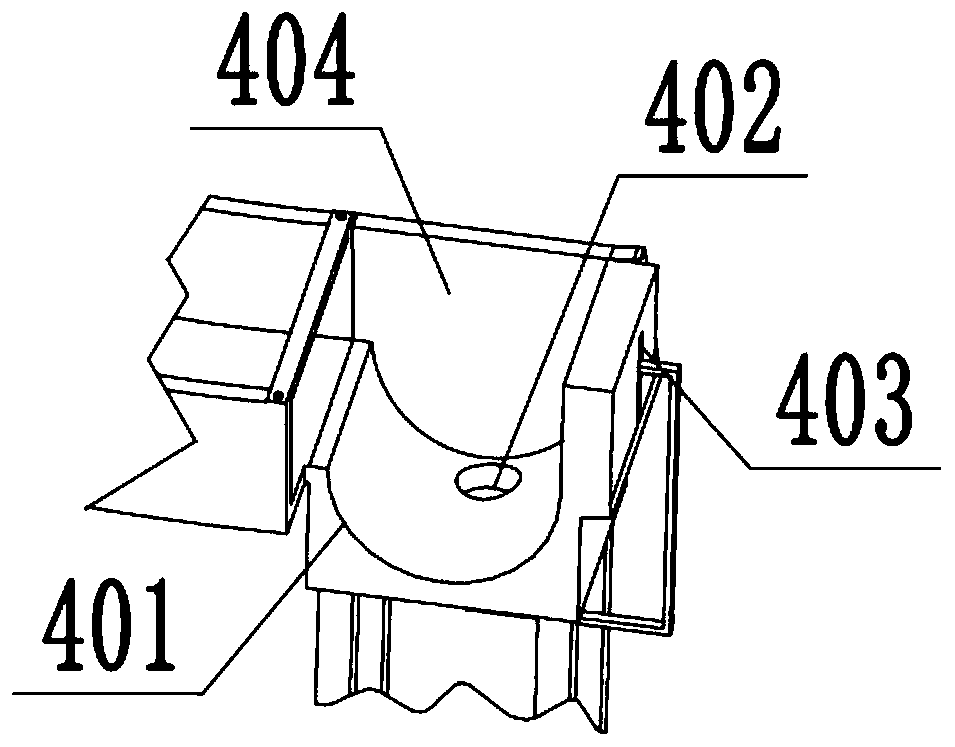

[0024] The processing base 4 is composed of a blanking groove processing opening 401, an upper push opening 402, an upper push rod reserved opening 403, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com