Method for continuously feeding carbon raw material and continuously removing slag in carbon disulfide production process by carbon method

A technology of carbon disulfide and process, applied in the direction of carbon disulfide, chemical instruments and methods, carbon sulfur compounds, etc., can solve problems such as feeding and slag removal difficulties, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

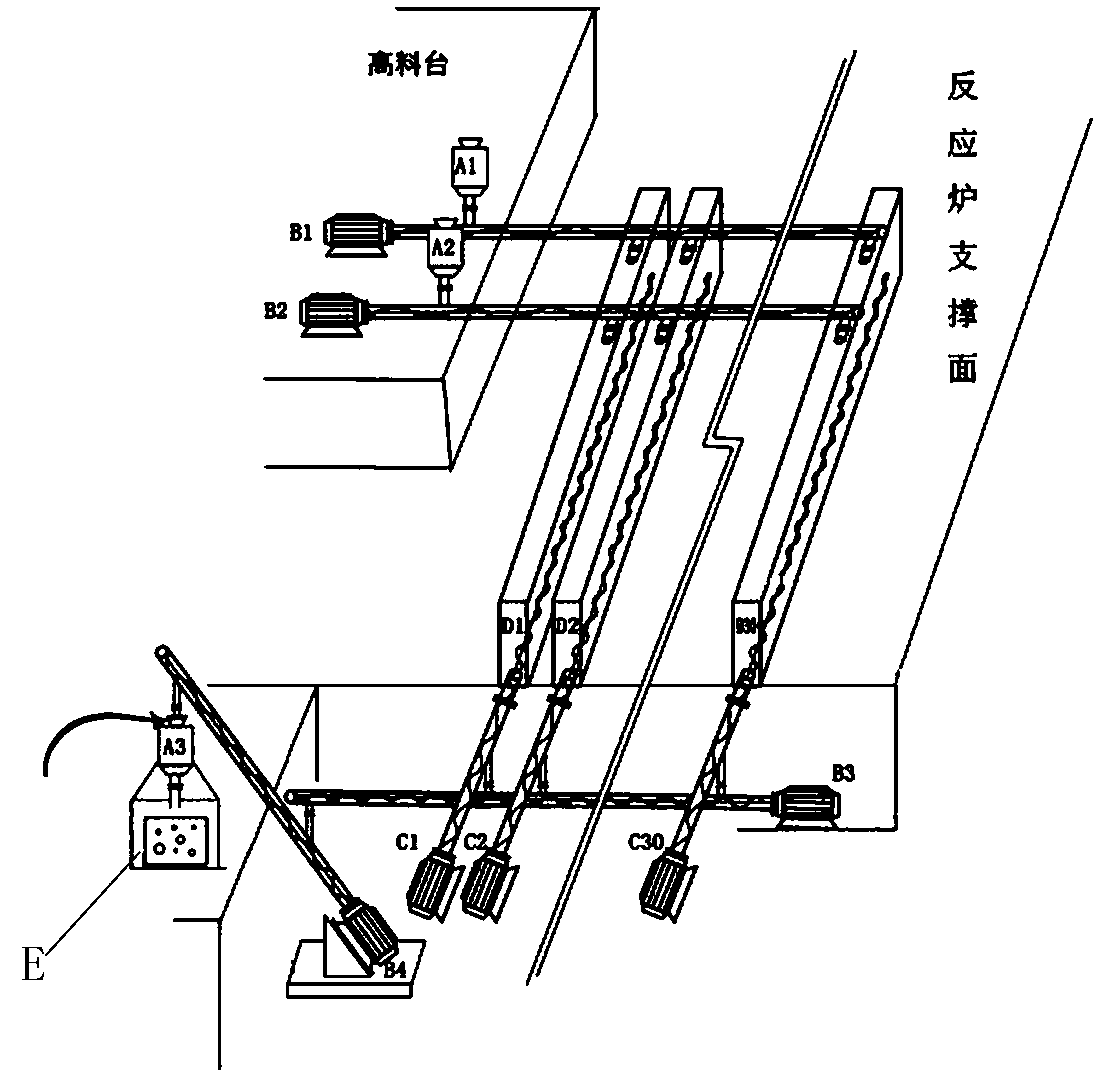

[0021] Taking the continuous feeding and continuous slag removal of the above-mentioned stainless steel reaction furnace in the process of producing 10,000 tons of carbon disulfide as an example, the explanation is as follows.

[0022] The stainless steel reaction furnace has a cuboid structure, the width of the reaction furnace is about 600mm, 30 reaction furnaces are arranged side by side on the same ground plane, and the distance between the reaction furnaces is about 120mm. There are two feeding ports on the top of each reactor, and the reactors are precisely arranged so that the 60 feeding ports on the top of the 30 reactors form two straight lines, and 30 of the feeding ports form a straight line. There is a slag outlet at the bottom of each reaction furnace, and the 30 slag outlets of the 30 reaction furnaces are arranged on the same side of the reaction furnace and on the same horizontal line.

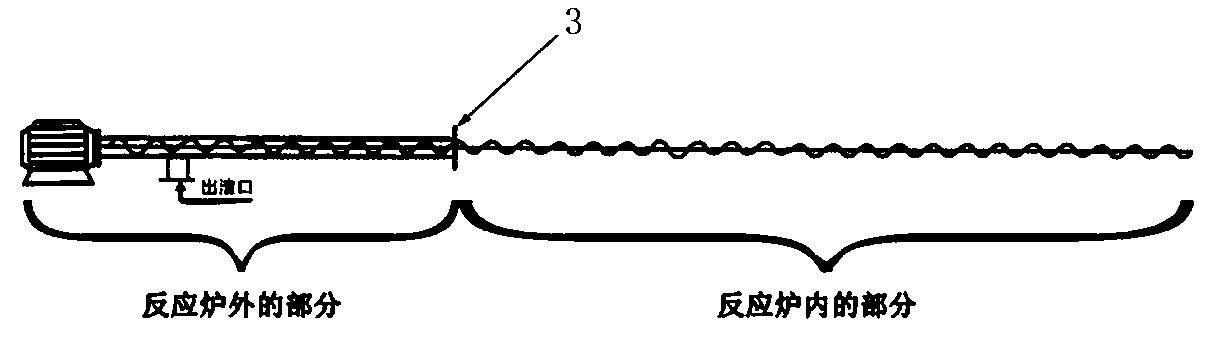

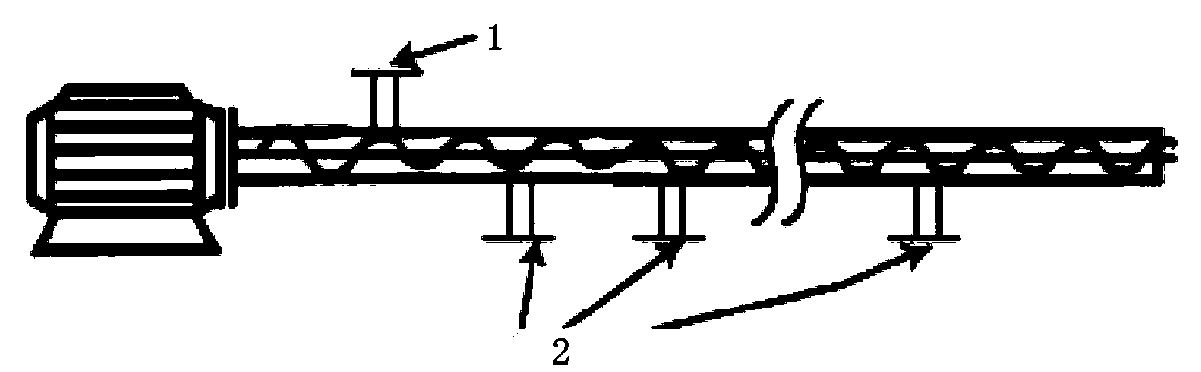

[0023] Two tubular propeller feeders are installed horizontally on the roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com