A kind of tempering heat treatment method of carburized parts and carburized parts

A heat treatment method, carburizing and quenching technology, applied in the field of carburized parts, carburized parts tempering heat treatment, can solve the problems of carburized parts, such as poor matching of strong plasticity, poor resistance to contact fatigue, poor service reliability, etc. The effect of long furnace time, optimized matching of strong plasticity and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

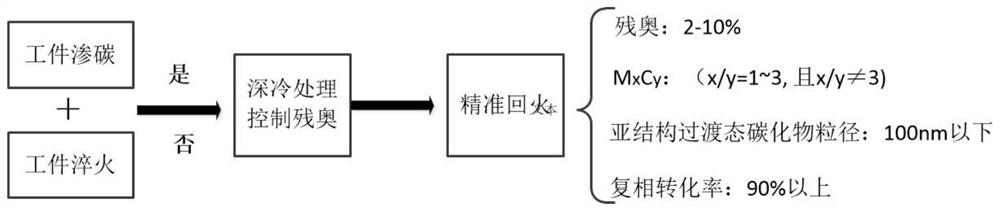

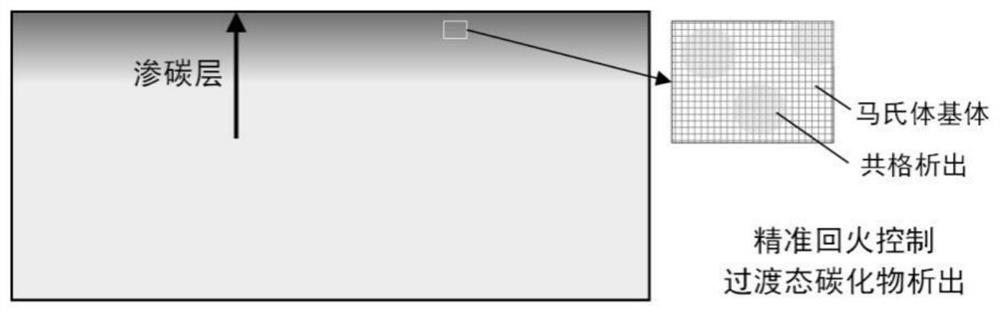

Method used

Image

Examples

Embodiment 1

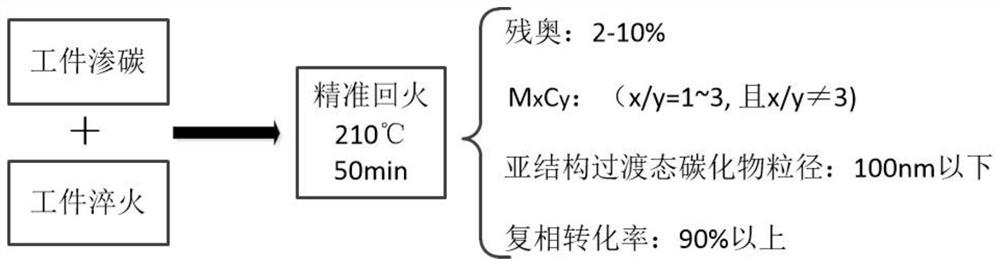

[0062] Taking 20CrMnTi carburized parts as the base material as an example, the preparation method of the heat treatment method to control the clustering of carbon atoms and the precipitation of substructure transition state carbides can be found in image 3 , the preparation method comprises the steps of:

[0063] Step 1: Carburize the 20CrMnTi part at 930°C for 10 hours, then oil-cool and quench the sample, and detect that the volume fraction of retained austenite is 8%, and no cryogenic treatment is performed;

[0064] Step 2: Place the parts after carburizing and quenching in a tempering furnace at 210° C., keep them warm for 360 minutes, and the generation rate of transition state carbides in the substructure of the samples reaches 90%, and then conduct water cooling treatment.

[0065] After the heat treatment is completed, the carburized layer structure of the 20CrMnTi carburized part is taken for analysis and evaluation. The microstructure characteristics under the tra...

Embodiment 2

[0067] Taking 20CrMnTi carburized parts as the base material as an example, the preparation method of precisely controlling the clustering of carbon atoms and the precipitation of substructure transition state carbides includes the following steps:

[0068] Step 1: Carburize the 20CrMnTi part at 930°C for 30 hours, then oil-cool and quench the sample, detect that the volume fraction of retained austenite is 15%, and perform cryogenic treatment with liquid nitrogen for 30 minutes;

[0069] Step 2: Place the parts after carburizing and quenching in a tempering furnace at 230° C. and keep them warm for 120 minutes. The conversion rate of transition state carbides in the internal substructure of the samples reaches 92%, and then water-cooling treatment.

[0070] The microstructure of the carburized layer after heat treatment is: low-carbon tempered martensite (volume fraction 97.4%) + retained austenite (volume fraction 1%) + high carbon martensite without precipitation of carbide...

Embodiment 3

[0072] Taking 18Cr2Ni4W carburized parts as the base material as an example, the preparation method of precisely controlling the clustering of carbon atoms and the precipitation of substructure transition state carbides includes the following steps:

[0073] Step 1: Carburize the 18Cr2Ni4W part at 930°C for 30 hours, then oil-cool and quench the sample, detect that the volume fraction of retained austenite is 12%, and perform cryogenic treatment for 2 hours.

[0074] Step 2: place the carburized and quenched 20CrMnTi part in a tempering furnace at 240° C., keep it warm for 90 minutes, and the conversion rate of transition state carbides inside the sample reaches 95%, and then water-cooling treatment.

[0075] The microstructure of the carburized layer after heat treatment is: low-carbon tempered martensite (volume fraction 97%) + retained austenite (volume fraction 1.3%) + high carbon martensite without precipitation of carbides (volume fraction 0.8%) + Fe 3C precipitation ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com