A method for preparing fe-based nanocrystalline alloy strips

A technology for nanocrystalline alloys and strips, which is applied in the field of external static magnetic field devices and the preparation of Fe-based nanocrystalline alloy strips, can solve the problem of not substantially improving the ability of alloy amorphous formation, high requirements for process parameter control, high Additional costs and other issues, to achieve the effect of improving the ability of amorphous formation and magnetic properties, wide application prospects, and reducing coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The Fe-based nanocrystalline alloy strip material provided by the present invention is prepared by an amorphous strip spraying machine, the amorphous strip spraying machine includes a quick-quenched copper roll, and the magnets in the external static magnetic field device are fixed on both sides of the quick-quenched copper roll, The preparation method comprises the following steps:

[0033] (1) Adjust the magnets fixed on both sides of the quick quenching copper roller, and adjust the magnetic field to 120-240mT;

[0034] (2) The alloy in the molten state is sprayed onto the quick-quenched copper roller in the step (1), and the strip is prepared;

[0035] (3) performing nanocrystallization treatment on the strip prepared in step (2), annealing, heat preservation, and water quenching to obtain Fe-based nanocrystalline alloy strip.

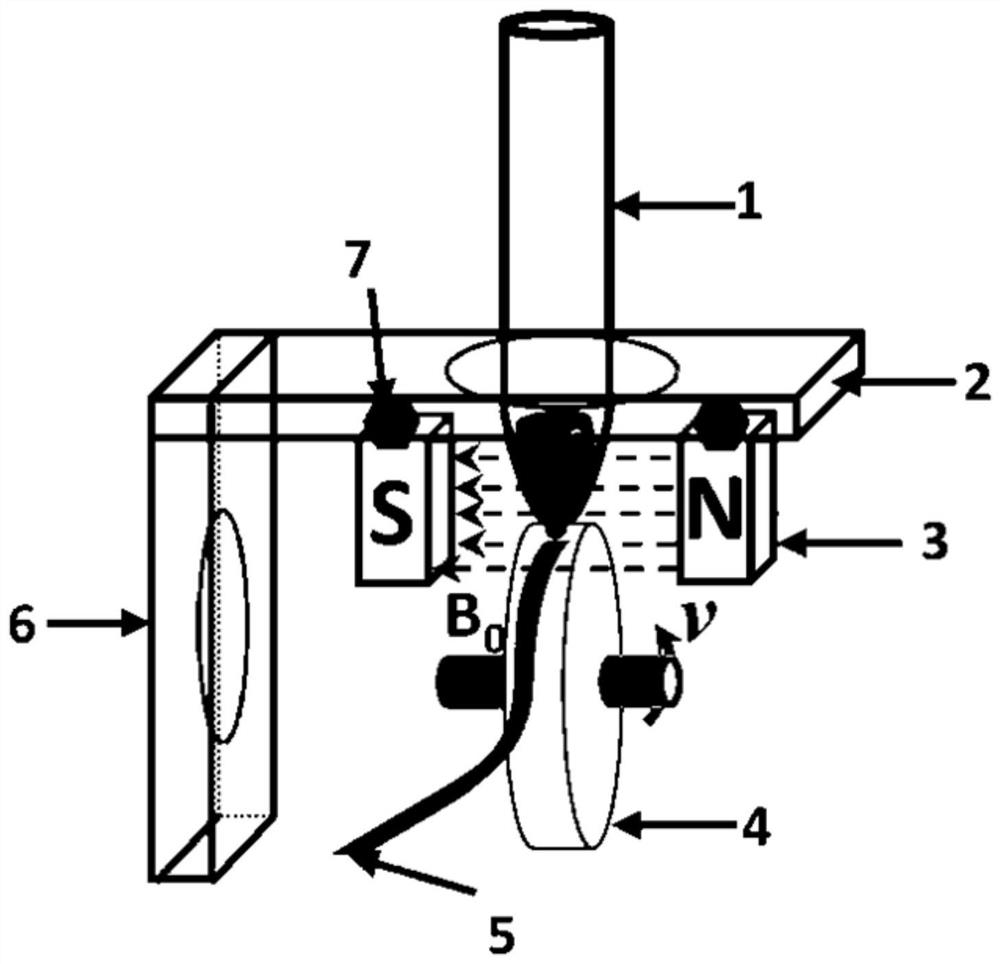

[0036] Such as figure 1 As shown, the applied static magnetic field device includes a magnet 3, a support structure and an adjustment uni...

Embodiment 1

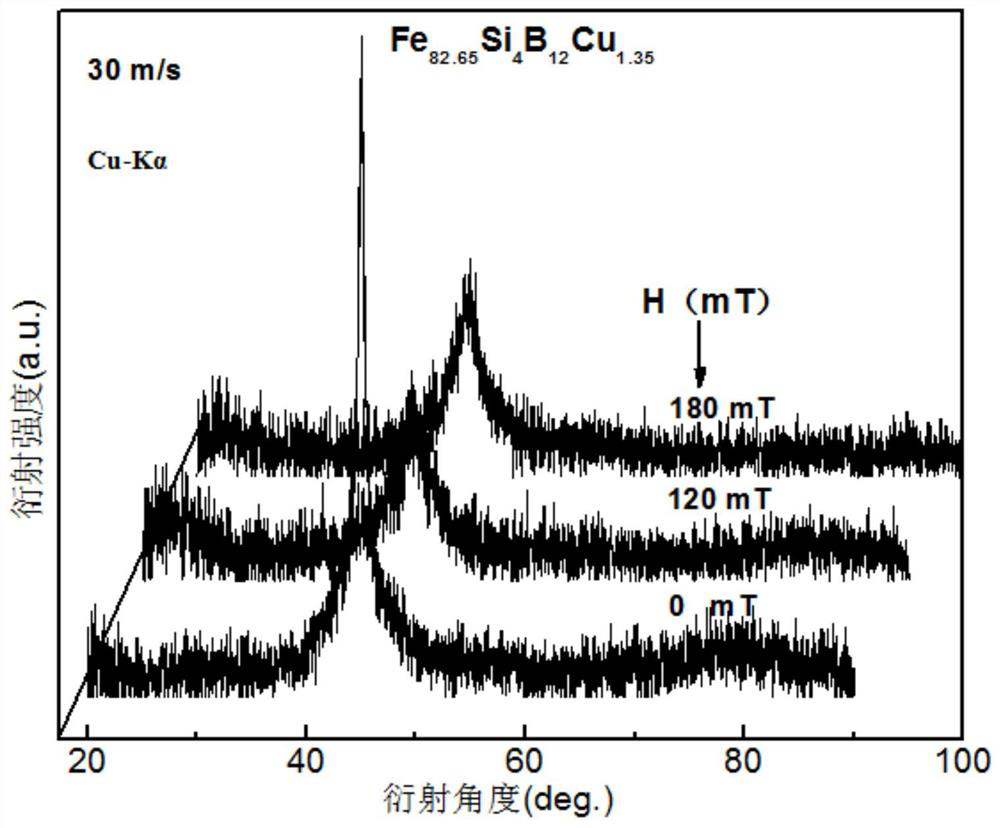

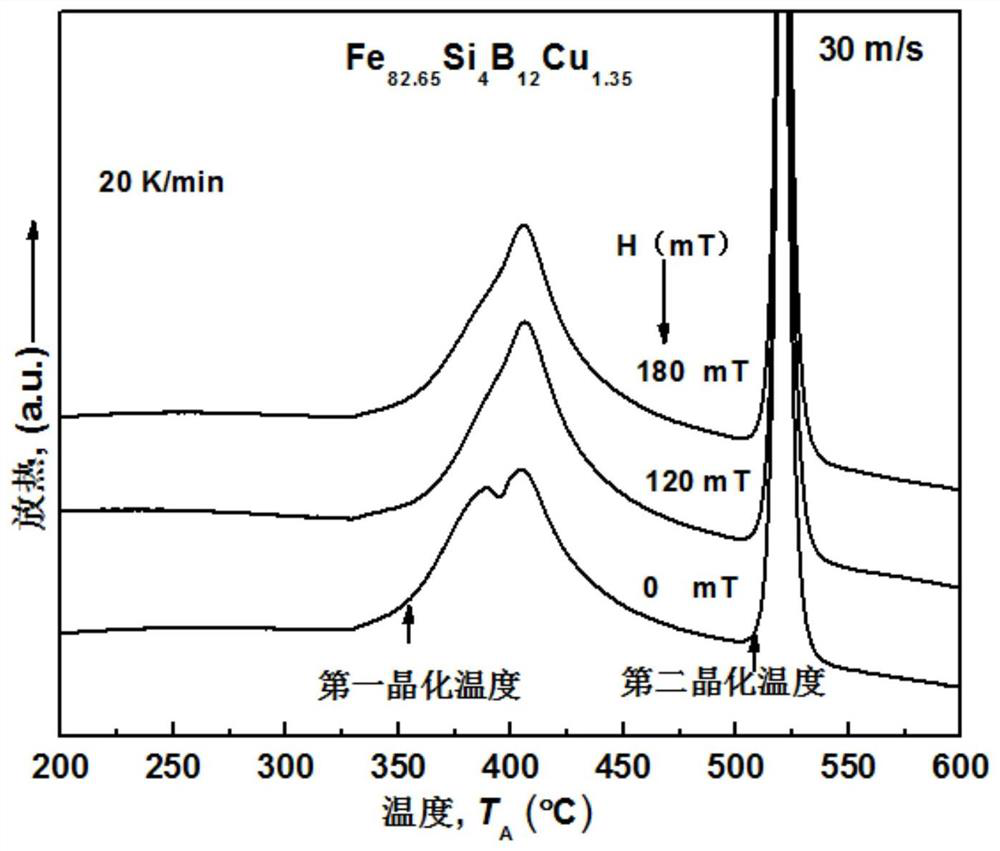

[0038] Preparation of Fe 82.65 Si 4 B 12 Cu 1.35 Nanocrystalline Alloy Ribbon:

[0039] (1) The external static magnetic field device is fixed on both sides of the quick quenching copper roller 4;

[0040] (2) Adjust the magnetic field strength to 120mT;

[0041] (3) Spray the alloy in the molten state in the quartz tube 1 onto the quenched copper roller 4 to prepare the strip 5;

[0042] (4) The strip material 5 after preparation carries out nanocrystallization treatment, and annealing temperature is 420 ℃, and holding time is 60 minutes, takes out water quenching, obtains Fe 82.65 Si 4 B 12 Cu 1.35 Nanocrystalline Alloy Ribbon.

Embodiment 2

[0044] Fe as provided in Example 1 82.65 Si 4 B 12 Cu 1.35 Nanocrystalline alloy ribbon, wherein the magnetic field strength is adjusted to 180mT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com