Novel high barrier spunbond ventilating material, preparation method and application

A high-barrier, new material technology, applied in the direction of textiles and papermaking, non-woven fabrics, absorbent pads, etc., can solve the problems of uneven fineness, high grammage, low barrier capacity, etc., and achieve excellent strength and elongation performance , Improve air permeability and comfort, high hydrostatic pressure resistance and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

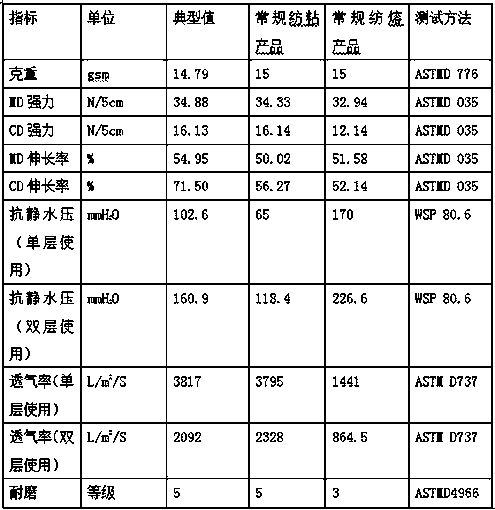

Image

Examples

Embodiment 1

[0032] Example 1 A new high-barrier spunbonded breathable material and its preparation method

[0033] A kind of preparation method of high-barrier spun-bonded breathable new material of the present invention, comprises the following steps:

[0034] (1) Material selection:

[0035] As for the selection of materials, high-quality and differentiated raw materials are selected.

[0036] The raw materials include S1 layer raw materials and S2 layer raw materials;

[0037] The raw materials of the S1 layer include PP material, soft masterbatch and white masterbatch, the addition amount of each masterbatch is: soft masterbatch 0.5%, white masterbatch 0.5%, and the rest is PP material;

[0038] The raw material of the S2 layer includes PP material, high barrier masterbatch and white masterbatch, the addition amount of each masterbatch is: 2% of high barrier masterbatch, 0.3% of white masterbatch, and the rest is PP material;

[0039] The PP material has an MFR range of 32-40g / 10mi...

Embodiment 2

[0053] Embodiment 2 A kind of high-barrier spun-bonded breathable new material and its preparation method

[0054] A kind of preparation method of high-barrier spun-bonded breathable new material of the present invention, comprises the following steps:

[0055] (2) Material selection:

[0056] As for the selection of materials, high-quality and differentiated raw materials are selected.

[0057] The raw materials include S1 layer raw materials and S2 layer raw materials;

[0058] The raw materials of the S1 layer include PP material, soft masterbatch and white masterbatch, the addition amount of each masterbatch is: soft masterbatch 1.5%, white masterbatch 0.5%, and the rest is PP material;

[0059] The raw materials of the S2 layer include PP material, high barrier masterbatch and white masterbatch, the addition amount of each masterbatch is: 2-8% of high barrier masterbatch, 1.1% of white masterbatch, and the rest is PP material;

[0060] The PP material has an MFR range ...

Embodiment 3

[0074] Embodiment 3 A kind of high-barrier spun-bonded breathable new material and its preparation method

[0075] A kind of preparation method of high-barrier spun-bonded breathable new material of the present invention, comprises the following steps:

[0076] (3) Material selection:

[0077] As for the selection of materials, high-quality and differentiated raw materials are selected.

[0078] The raw materials include S1 layer raw materials and S2 layer raw materials;

[0079] The raw materials of the S1 layer include PP material, soft masterbatch and white masterbatch, the addition amount of each masterbatch is: soft masterbatch 2%, white masterbatch 0.5%, and the rest is PP material;

[0080] The raw materials of the S2 layer include PP material, high barrier masterbatch and white masterbatch, the addition amount of each masterbatch is: 8% of high barrier masterbatch, 1% of white masterbatch, and the rest is PP material;

[0081] The PP material has an MFR range of 32-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com