Thermal transfer printing method for waterproof moisture-permeable nanofiber membrane

A nanofiber film, thermal transfer printing technology, applied in transfer printing, printing, dyeing and other directions, can solve the problems of difficult and difficult coloring, achieve good light fastness, bright colors, and shorten the delivery time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A thermal transfer printing method for a waterproof and moisture-permeable nanofiber membrane, the steps are as follows:

[0035] (1) Print the designed pattern on the transfer printing paper by printing.

[0036] (2) Place the waterproof and moisture-permeable nanofiber membrane on the thermal transfer printing equipment, and then put the patterned side of the transfer printing paper in close contact with the waterproof and moisture-permeable nanofiber membrane at a pressure of 2.1 MPa, and then heat it at 100 °C The temperature is maintained for 70s, and the printed waterproof and moisture-permeable nanofiber membrane is bonded with the transfer printing paper.

[0037] (3) Take it out from the thermal transfer printing machine, and then separate the printed waterproof and moisture-permeable nanofiber membrane from the transfer printing paper. The separation tension is 3N, the speed is 10cm / s and the direction is 80°, and the waterproof and moisture-permeable membrane...

Embodiment 2

[0040] A thermal transfer printing method for a waterproof and moisture-permeable nanofiber membrane, the steps are as follows:

[0041](1) Print the designed pattern on the polymer film by printing.

[0042] (2) The waterproof and moisture-permeable nanofiber membrane is placed on the thermal transfer printing equipment, and then the side printed with the pattern on the polymer film is in close contact with the waterproof and moisture-permeable nanofiber membrane, the pressure is 1.8 MPa, and then the water-proof and moisture-permeable nanofiber membrane is pressed at 120 ℃ for 40s, and the printed waterproof and moisture-permeable nanofiber membrane is laminated with the polymer film.

[0043] (3) Take it out from the thermal transfer printing machine, and then separate the printed waterproof and moisture-permeable nanofiber membrane from the polymer film. The separation tension is 4N, the speed is 30cm / s and the direction is 70°, and the waterproof and moisture-permeable me...

Embodiment 3

[0046] A thermal transfer printing method for a waterproof and moisture-permeable nanofiber membrane, the steps are as follows:

[0047] (1) Print the designed pattern on the polymer film by printing.

[0048] (2) The waterproof and moisture-permeable nanofiber membrane is placed on the thermal transfer printing equipment, and then the side printed with the pattern on the polymer film is in close contact with the waterproof and moisture-permeable nanofiber membrane, and the pressure is 1.5 MPa. ℃ for 30s, and the printed waterproof and moisture-permeable nanofiber membrane is laminated with the polymer film.

[0049] (3) Take it out from the thermal transfer printing machine, and then separate the printed waterproof and moisture-permeable nanofiber membrane from the polymer film. The separation tension is 2.5N, the speed is 35cm / s and the direction is 120°, and the waterproof membrane can be obtained. Moisture-permeable nanofiber membrane printing products.

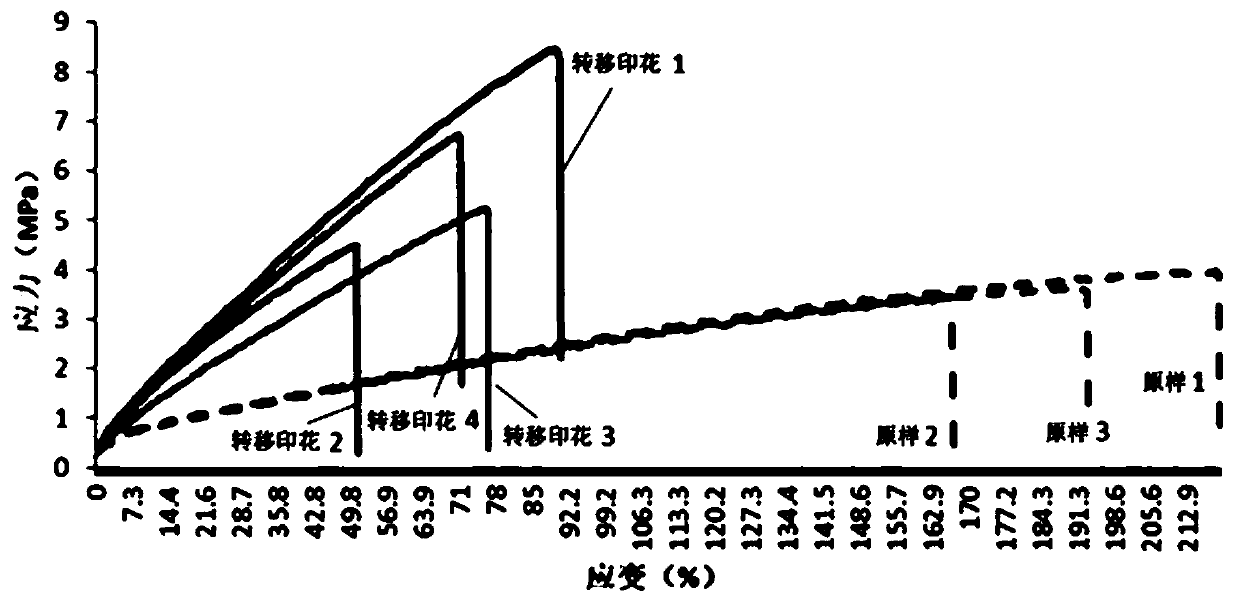

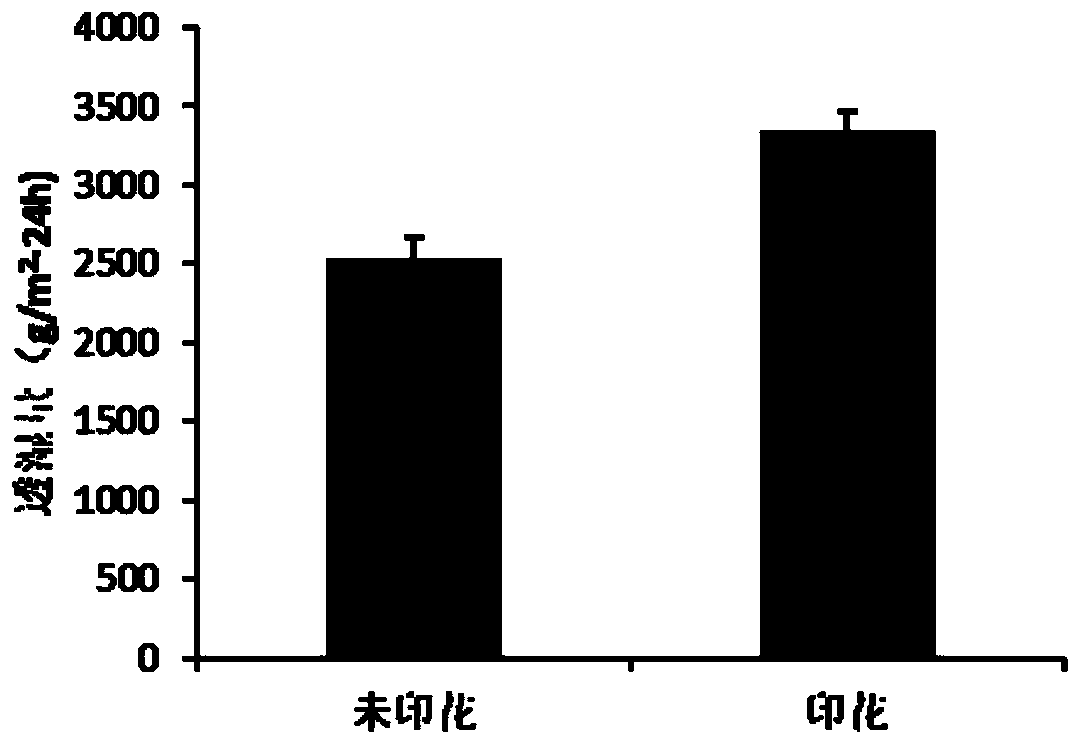

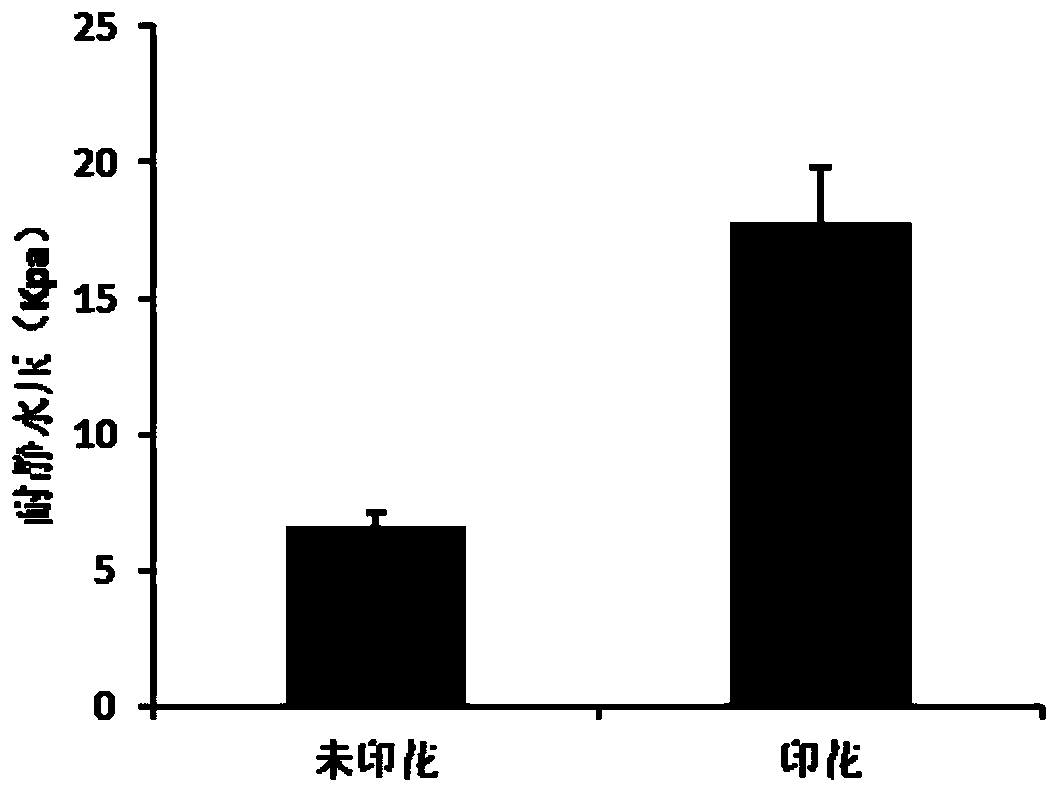

[0050] The test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com