Preparation method for ultraviolet aging-resistant breathable film

A breathable film, UV-resistant technology, applied in flat products, applications, household appliances, etc., can solve problems such as restricting popularization and application, weakening the effect of adjusting humidity, etc., to widen the application range, improve water vapor permeability, improve resistance The effect of UV aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

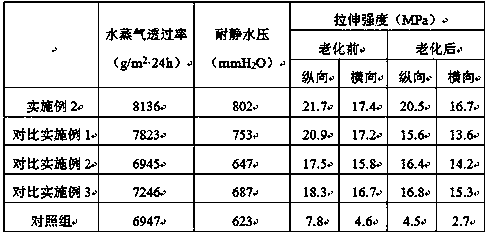

Examples

Embodiment 1

[0031] A preparation method for an ultraviolet aging-resistant breathable film, comprising the steps of:

[0032] (1) Preparation of modified composite filler:

[0033] a. Mix octadecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl benzyl ammonium bromide, and deionized water according to the weight ratio of 1:2.3:82, then put them into the stirring tank, and heat After reaching 70°C, put the nano-silica into the stirring tank, stir at 70°C for 30 minutes, centrifuge to remove the supernatant, wash with sterile water for 3 times, and dry to obtain powder A;

[0034] b. Put the powder A and nano-titanium dioxide obtained in operation a into the bead mill for grinding according to the weight ratio of 1:7, and after grinding for 23 minutes, get the powder B for subsequent use;

[0035] c. Pour the ammonium fluoride solution with a mass fraction of 3% into the electrolytic cell, add ammonia water dropwise to adjust the pH of the solution to 7.8, then immerse the powder B ob...

Embodiment 2

[0053] A preparation method for an ultraviolet aging-resistant breathable film, comprising the steps of:

[0054] (1) Preparation of modified composite filler:

[0055] a. Mix octadecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl benzyl ammonium bromide, and deionized water in a weight ratio of 1.5:2.35:86, then put them into the stirring tank, and heat After reaching 80°C, put nano silicon dioxide into a stirring tank, stir at 80°C for 35 minutes, centrifuge to remove the supernatant, wash with sterile water for 4 times, and dry to obtain powder A;

[0056] b. The powder A obtained in operation a and the nano-titanium dioxide are put into the bead mill for grinding according to the weight ratio of 1.5:7.5, and after grinding for 24 minutes, the powder B is obtained for subsequent use;

[0057] c. Pour the ammonium fluoride solution with a mass fraction of 4% into the electrolytic cell, add ammonia water dropwise to adjust the pH of the solution to 7.9, then immerse t...

Embodiment 3

[0075] A preparation method for an ultraviolet aging-resistant breathable film, comprising the steps of:

[0076] (1) Preparation of modified composite filler:

[0077] a. Mix octadecyl dimethyl benzyl ammonium chloride, dodecyl dimethyl benzyl ammonium bromide, and deionized water in a weight ratio of 2:2.4:90, then put them into the stirring tank, and heat After reaching 90°C, put the nano-silica into the stirring tank, stir at 90°C for 40 minutes, centrifuge to remove the supernatant, wash with sterile water for 5 times, and dry to obtain powder A;

[0078] b. Put the powder A and nano-titanium dioxide obtained in operation a into the bead mill for grinding according to the weight ratio of 2:8, and after grinding for 25 minutes, get the powder B for subsequent use;

[0079] c. Pour the ammonium fluoride solution with a mass fraction of 5% into the electrolytic cell, add ammonia water dropwise to adjust the pH of the solution to 8, then immerse the powder B obtained in oper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com