A pulp preparation device for regenerated fiber

A technology for regenerated fiber and pulp, applied in fiber raw materials, fiber raw material treatment, raw material separation, etc., can solve the problems of low production efficiency of recycled fiber pulp, achieve enhanced contact adsorption effect, improve mixing effect, and enhance efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

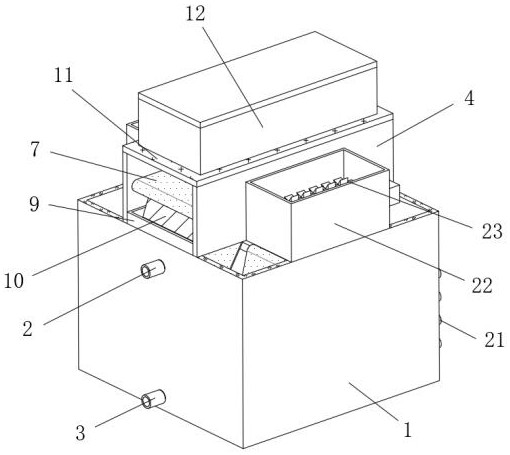

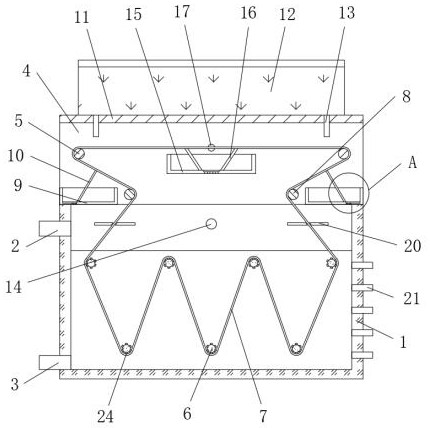

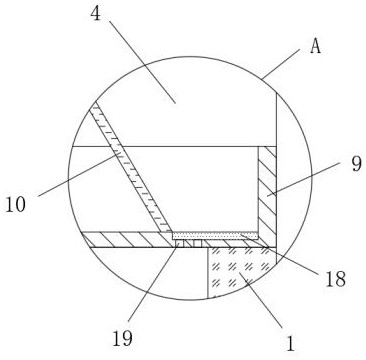

Embodiment 1

[0032] refer to Figure 1-5, a pulp production device for regenerated fiber, comprising a box 1 with an open top, the top and bottom of the outer wall on one side of the box 1 are respectively connected with a water inlet pipe 2 and a pulp outlet pipe 3, and the two ends of the top of the box 1 Both fixed plates 4 are fixed, and both sides of the top between the two fixed plates 4 are rotatably connected with driving rollers 5, the driving rollers 5 are connected with drive motors, and the inner walls at both ends of the box body 1 are rotatably connected with limiting rollers 6 , and a belt 7 is rotatably connected between the outer wall of the drive roller 5 and the limit roller 6, a scraper 10 is provided at the position corresponding to the top of the box body 1 and the belt 7, and both sides of the bottom between the two fixed plates 4 are rotatably connected There are tension rollers 8, and the distance between the two tension rollers 8 is less than the distance between ...

Embodiment 2

[0041] refer to Figure 1-6 , a pulp production device for regenerated fiber, rotating rods 26 distributed equidistantly in the horizontal direction are connected between the inner walls of the two ends of the box body 1, and the rotating rods 26 correspond to the positions of the limit rollers 6, and the rotating rods The outer wall of 26 is fixed with a plurality of arc-shaped guide vanes 27 , and the guide vanes 27 are inclined toward the end inner wall of the box body 1 .

[0042] When in use, during the flow of the slurry, the rotating rod 26 and the guide vane 27 on its outer wall are driven to rotate, so that the slurry flows toward the end along the guide vane 27 inclined to the end, thereby further strengthening the inner surface of the box body 1. The flow effect of the slurry further enhances the actual deinking and pulping efficiency of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com