A ground heating device for low-maturity oil shale and its application and evaluation method

A ground heating and heating device technology, which is applied in ground mining, measuring devices, underground mining, etc., to achieve the effect of reducing energy waste, reducing energy waste, and promoting maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

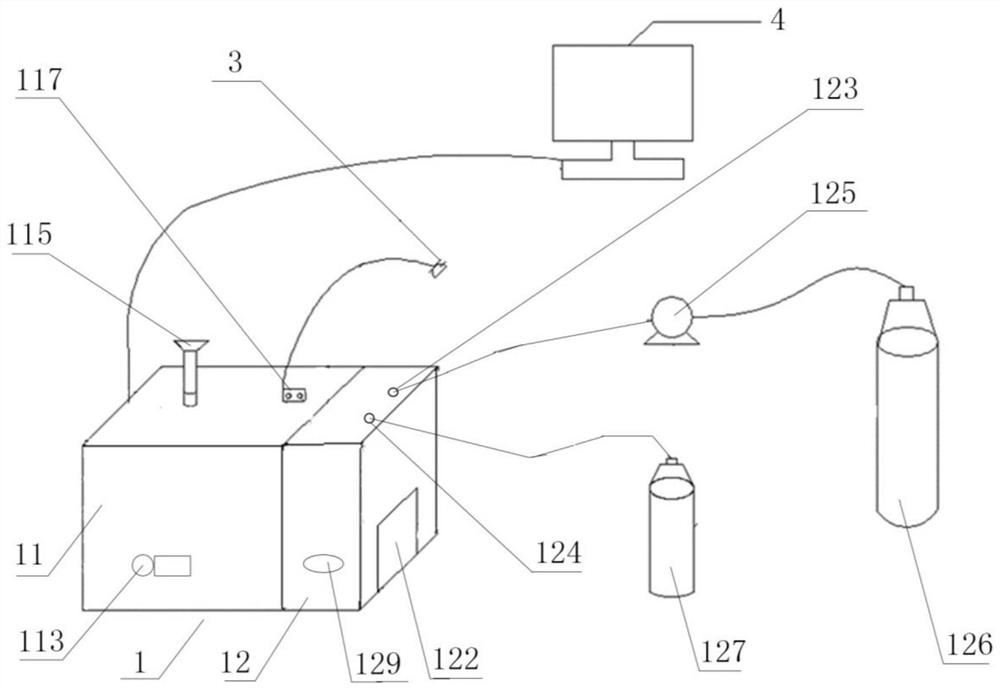

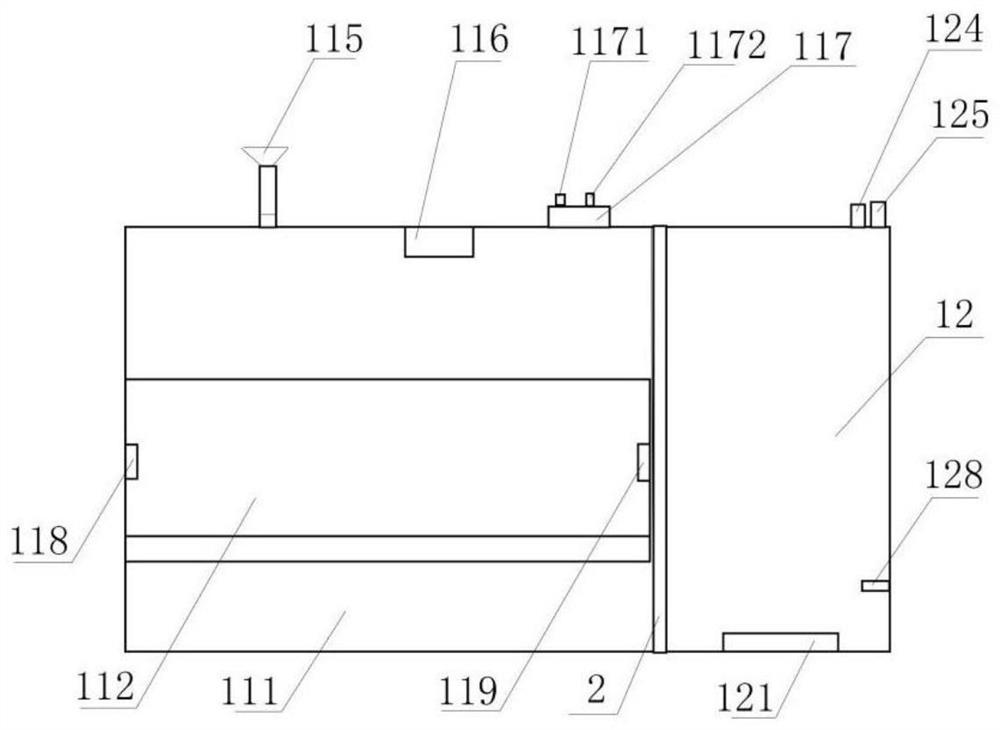

[0054] see figure 1 . This embodiment provides a ground heating device for low-maturity oil shale, including a heating device body 1, the heating device body 1 is divided into a heating chamber 11 and a cooling chamber 12 by a partition 2;

[0055] The bottom of the heating chamber 11 is welded with a resistance heating box 111, and a heating furnace 112 is movably connected in the resistance heating box 111;

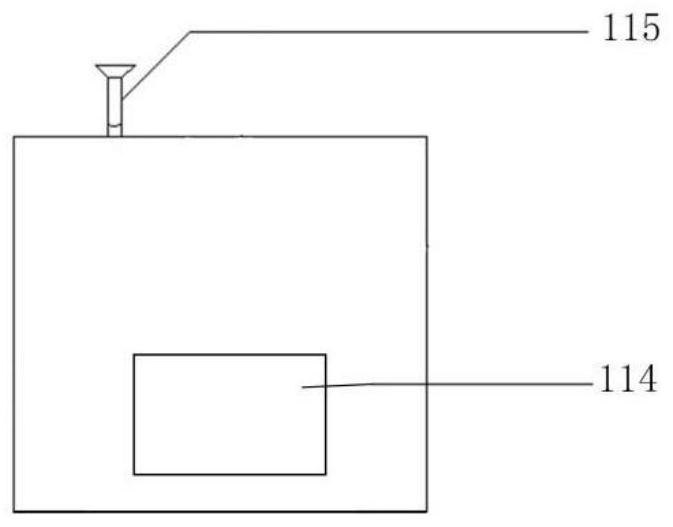

[0056] One side of the heating chamber 11 is provided with a temperature control knob 113 for controlling the heating temperature in the heating furnace 112; the left side of the heating chamber 11 is provided with a furnace door 114 for switching the heating furnace 112, and the furnace door One side of the furnace door 114 is connected to the side of the heating chamber 11 through a hinge, and the other side of the furnace door 114 is movably connected to the side of the heating chamber 11 through a magnetic strip. The inside of the furnace door 114 is provided with ...

Embodiment 2

[0068] This embodiment provides an application of a ground heating device for low-maturity oil shale in ground assessment of immature oil shale.

Embodiment 3

[0070] On the basis of Embodiment 1 and Embodiment 2, this embodiment provides a method for evaluating low-maturity oil shale ground using the low-maturity oil shale ground heating device, including:

[0071] Step 1, sample preparation: crush 300g of oil shale samples, and take 150g of samples to analyze the organic species of oil shale by Fourier transform infrared spectrometer; another 60g samples are used for mercury intrusion experiment; The 60g sample was tested for its oil content by the chloroform asphalt A method; the remaining samples were reserved for subsequent use;

[0072] Step 2, stand still: put the sample after Fourier transform infrared spectroscopic analysis in a nitrogen environment for 20 minutes;

[0073] Step 3, vacuuming: Connect the power plug to the power supply, open the furnace door of the heating chamber, put the sample after step 2 standing in the heating furnace, close the furnace door, turn on the switch A on the control switch, start the vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com