Double-stage steam compressor device

A technology of steam compressors and compressors, which is applied to pump devices, components of pumping devices for elastic fluids, mechanical equipment, etc., and can solve problems such as obstacles to economic returns, energy waste, and high failure rates of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

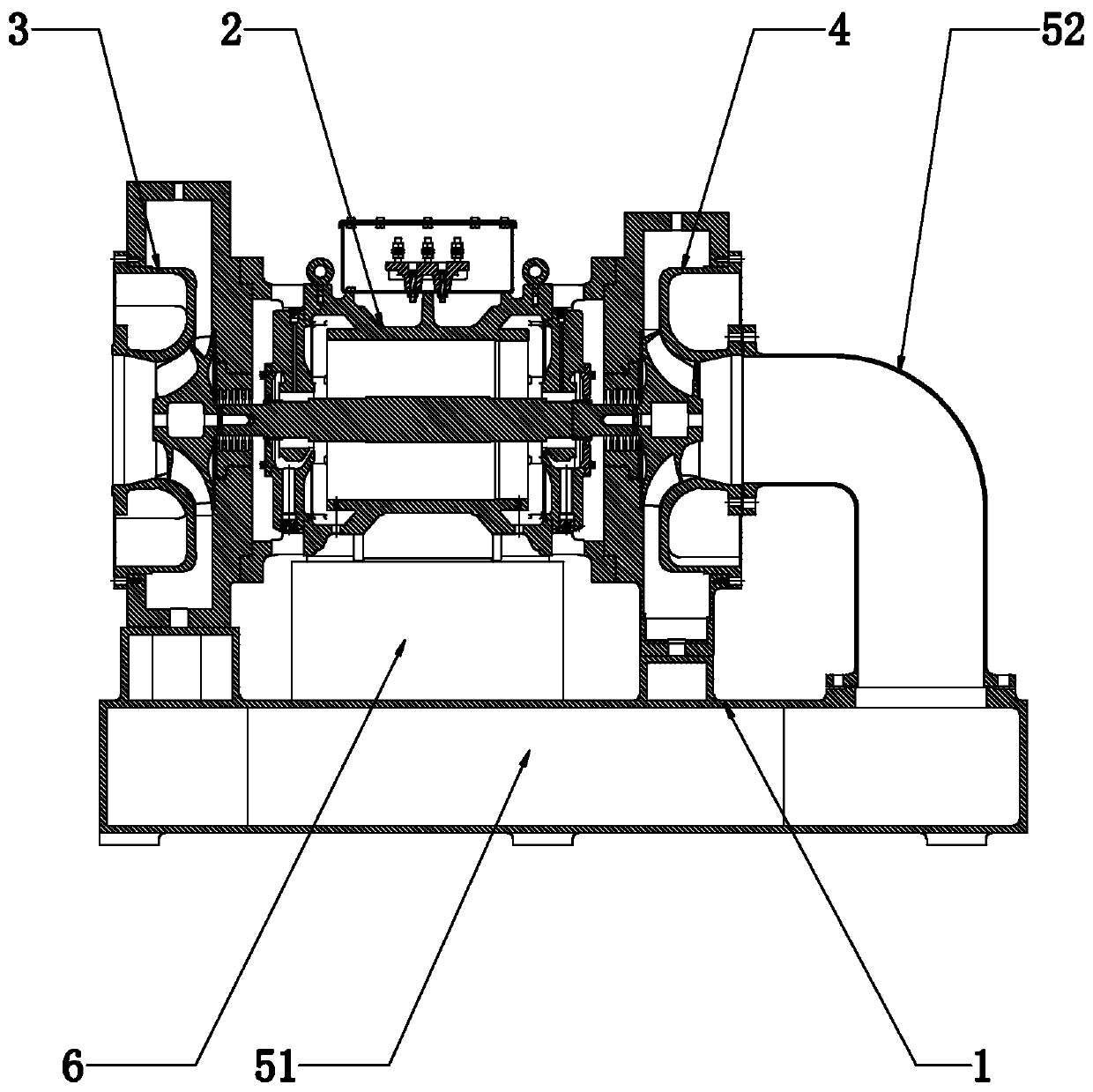

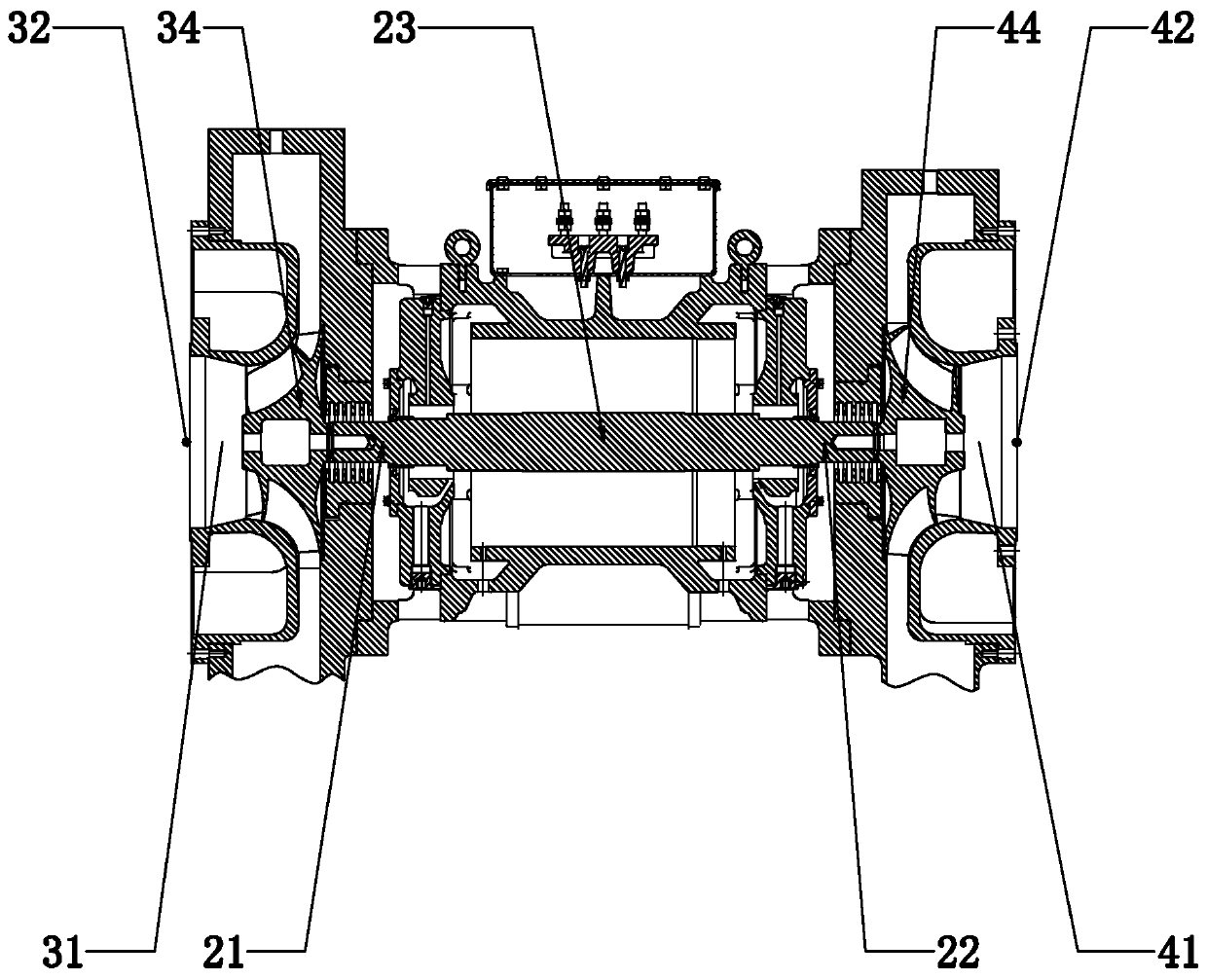

[0018] Such as figure 1 to figure 2 As shown, the present invention discloses a two-stage vapor compressor device, including a base 1, a motor 2 installed on the base 1, and a first-stage compressor head 3, and the first-stage compressor head 3 is provided with a first-stage diffuser flow channel 31 and a first-stage impeller 34 located in the flow passage, the first-stage impeller 34 is driven to rotate by the motor 2, the first-stage diffuser flow passage 31 is provided with a first-stage inlet 32 and a first-stage outlet 33, and the first-stage inlet 32 is connected to the steam source, and includes The two-stage compressor head 4 and the connecting channel 5 are arranged on the base 1. The two-stage compressor head 4 is provided with a two-stage diffuser flow channel 41 and a two-stage impeller 44 located in the flow channel. The two-stage impeller 44 is driven by the motor 2 Drive rotation, the secondary diffuser channel 41 is provided with a secondary inlet 42 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com