Three-way vibration test sensor based on additive manufacturing technology and preparation method

A technology of vibration testing and additive manufacturing, applied in the field of testing, can solve the problems of difficult to achieve uniform molding of composite materials, complicated preparation process, backward preparation process, etc., and achieve the effect of consistent structure and performance, easy to carry, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

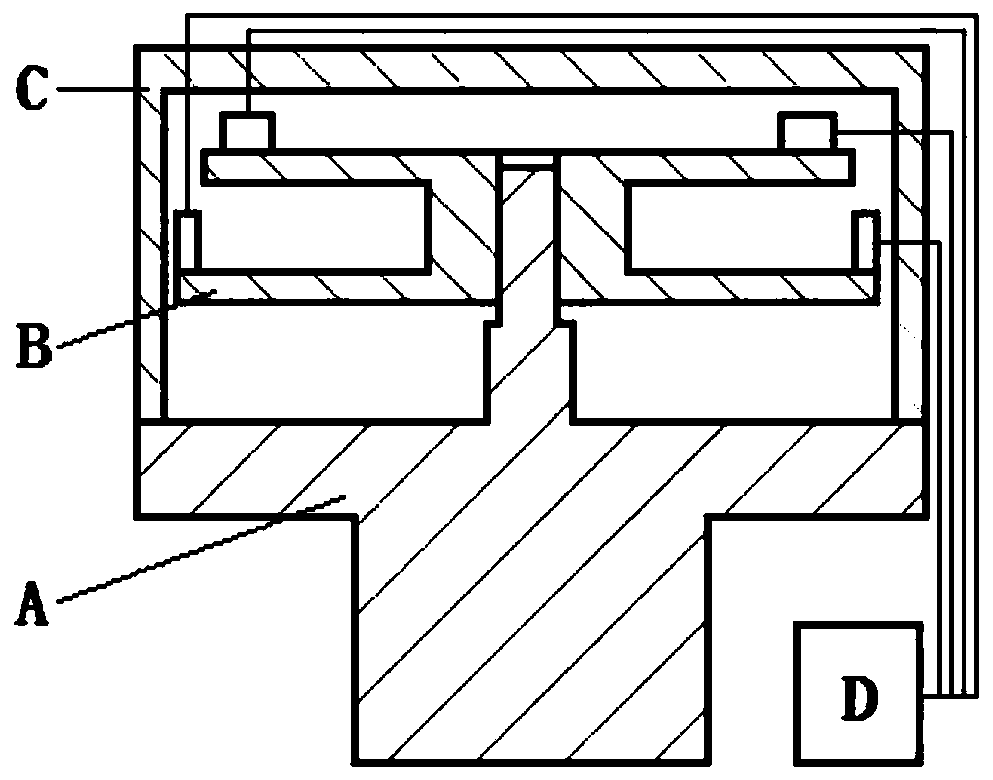

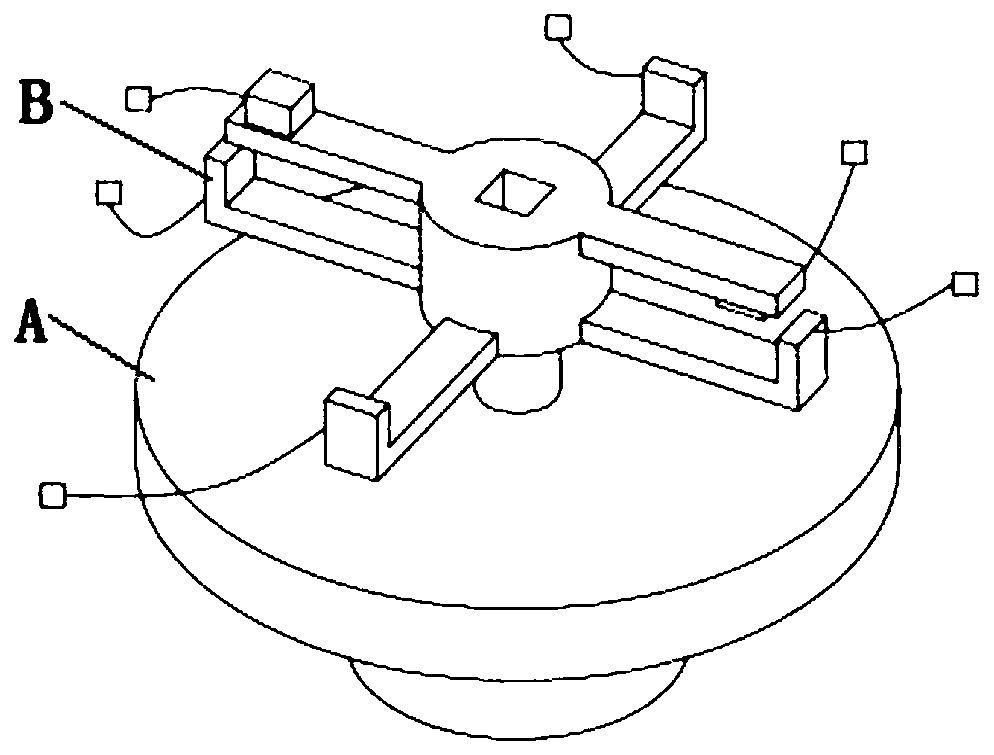

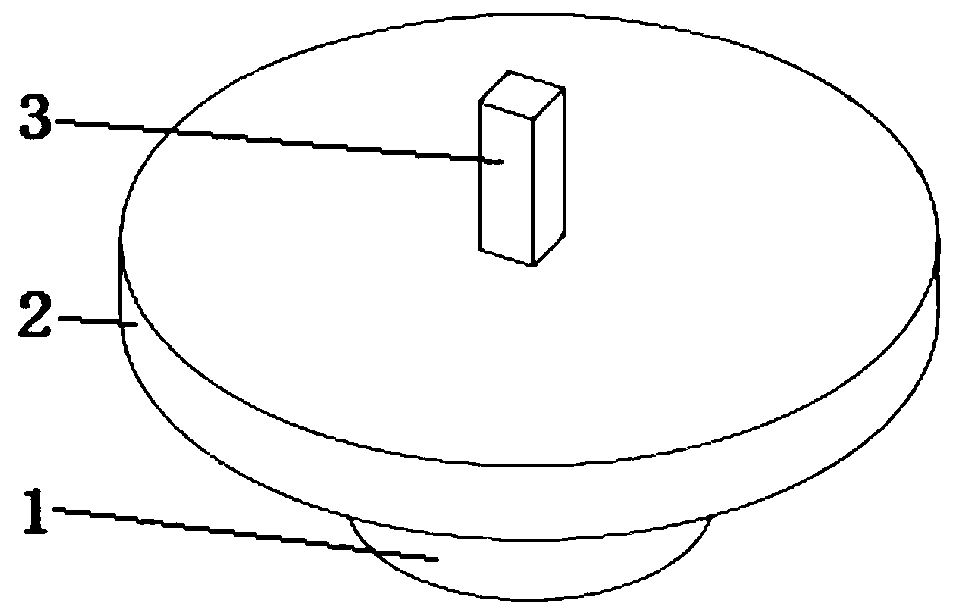

[0053] Such as Figure 1 to Figure 3 As shown, the three-way vibration test sensor based on additive manufacturing technology of the present invention is composed of a base A, a vibration test assembly B, a sensor housing C and a data management module D, wherein the base A is composed of a chassis 1, a middle plate 2 and a center pole 3 Composition, the chassis 1, the middle plate 2 and the center rod 3 are arranged and fixed in sequence from bottom to top; the center hole 6 of the cylinder 13 in the vibration test component B is fixed to the center rod 3 of the base A, and the lower end of the sensor housing C is fixed On the top of the middle plate 2 in the base A; the data input end of the vibration signal acquisition card 35 in the information management module D and the induction component I4, the induction component III8, the induction component II10, the induction component IV11, the induction component V15 and the vibration test component B in the vibration test compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com