A high-precision polarization-maintaining optical fiber and its preparation method

A polarization-maintaining optical fiber, high-precision technology, applied in the direction of polarized optical fiber, clad optical fiber, glass manufacturing equipment, etc., can solve the problems of low sensitivity or stability of sensor devices, low sensor accuracy, poor attenuation and extinction ratio performance, etc. , to optimize the birefringence effect and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

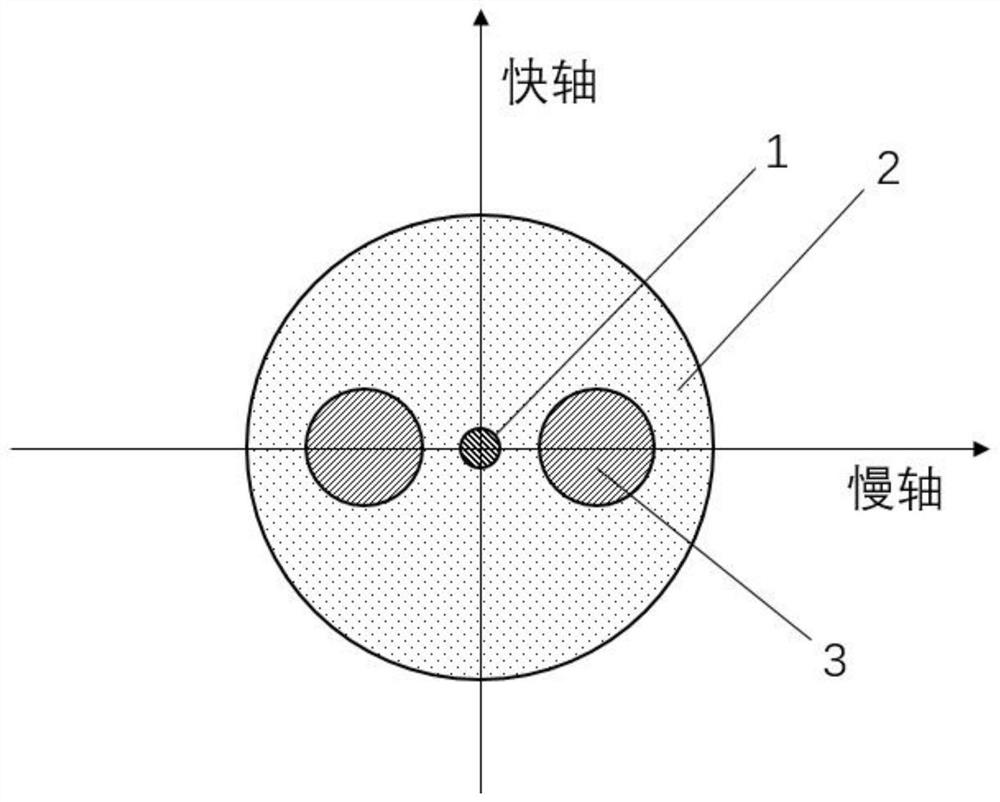

[0053] The preparation method of the high-precision polarization-maintaining optical fiber provided by the present invention includes the following steps: heating the optical fiber preform of the silica glass matrix to a viscoelastic state or even a molten state, and then drawing and cooling to form an optical fiber; wherein:

[0054] Drawing step: the drawing speed is above 100 m / min; during the drawing process, the tension along the fiber movement direction that the optical fiber bears in the viscoelastic state is 11 MPa to 75 MPa, preferably 15 MPa to 45 MPa, more preferably 20 MPa to 35 MPa.

[0055] Cooling step: the optical fiber is forcedly cooled from the drawing furnace to the take-up device, and the cooling rate is 1550°C / s to 5800°C / s, preferably 1550°C / s to 4000°C / s, more preferably 1550°C / s to 3000°C / s.

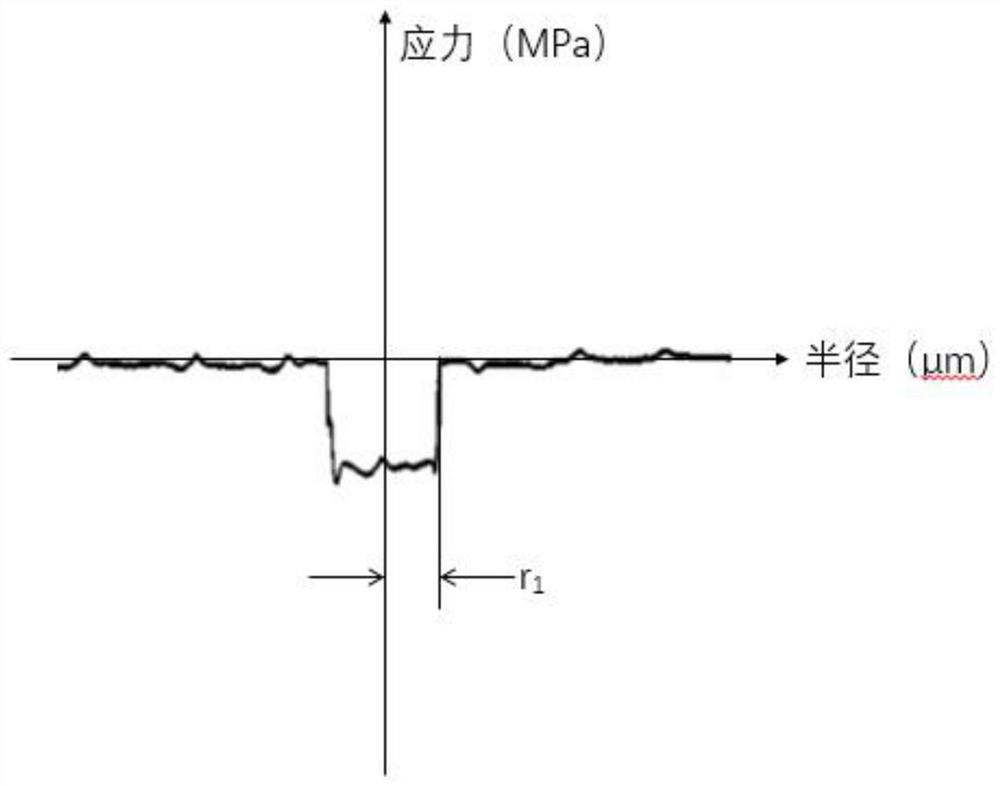

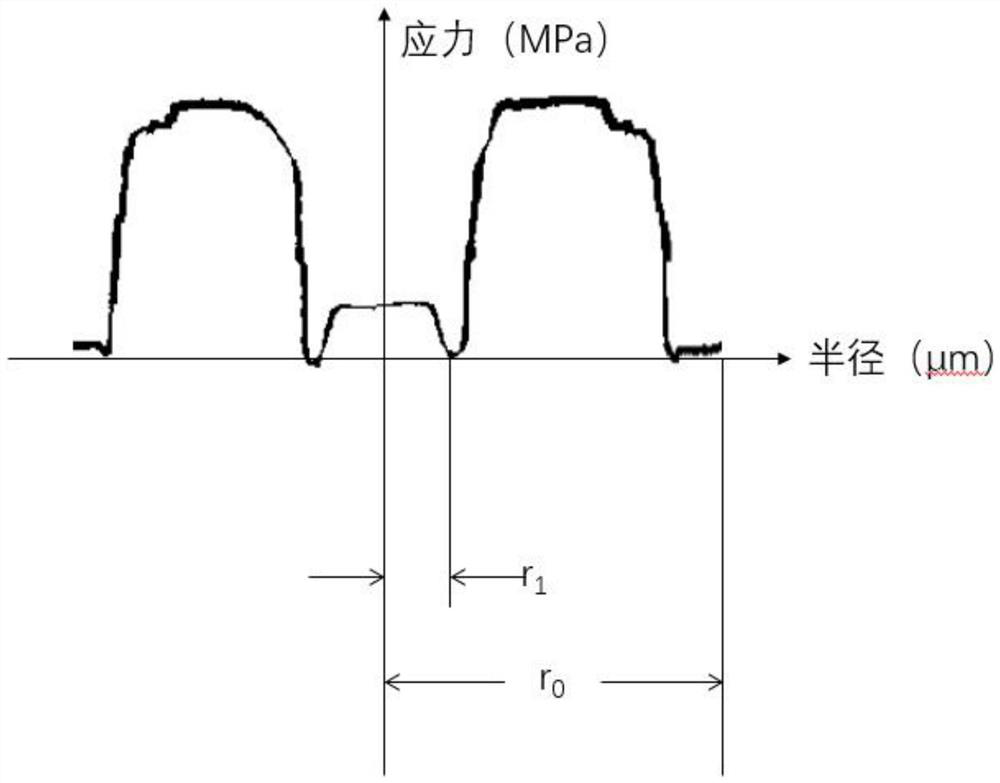

[0056] During the cooling process of wire drawing, the stress region and cladding of the fiber are transformed from viscoelastic state to solid state, and the r...

Embodiment 1

[0071] The first batch of cladding diameter d 0 The typical value of the polarization-maintaining fiber is 125 μm. The core rod is prepared by PCVD, MCVD, VAD, etc., and the stress area is made by PCVD, MCVD, chemical synthesis, etc. At a high temperature of 2300 °C, the optical fiber preform of the quartz glass matrix is heated to a molten state, and the fiber is drawn and cooled to form an optical fiber; the drawing speed is above 100 m / min; the optical fiber is forced to cool by dry ice purging during the process from the drawing furnace to the take-up device. , the cooling rate is 1550°C / s to 4000°C / s. During the drawing process, the tension along the motion direction of the optical fiber in the viscoelastic state is 11MPa to 45MPa, and the drawing tension is equal to the ratio of the tension force on the bare fiber during the drawing process to the optical fiber cross-sectional area. During the cooling process, the stress region and cladding of the fiber are transforme...

Embodiment 2

[0075] The second batch of cladding diameter d 0 The typical value of the polarization-maintaining fiber is 80 μm. The core rod is prepared by PCVD, MCVD, VAD, etc., and the stress area is made by PCVD, MCVD, chemical synthesis, etc. At a high temperature of 2300 °C, the optical fiber preform of the quartz glass matrix is heated to a molten state, and the fiber is formed by drawing and cooling; the drawing speed is above 100 m / min; the optical fiber is forced to cool by helium gas during the process from the drawing furnace to the take-up device. Cooling rate 1550°C / s to 3000°C / s. During the drawing process, the tension along the motion direction of the optical fiber in the viscoelastic state is 11MPa to 45MPa, and the drawing tension is equal to the ratio of the tension force on the bare fiber during the drawing process to the optical fiber cross-sectional area. During the cooling process, the stress region and cladding of the fiber are transformed from viscoelastic state ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com