Switched reluctance motor vibration and noise reduction method based on motor structure characteristics

A switched reluctance motor, vibration reduction and noise reduction technology, applied in the direction of motor vibration suppression, AC motor control, electrical components, etc., can solve the problems of limited vibration reduction and noise reduction effect, poor torque pulsation effect, etc. Low, simple operation, to achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

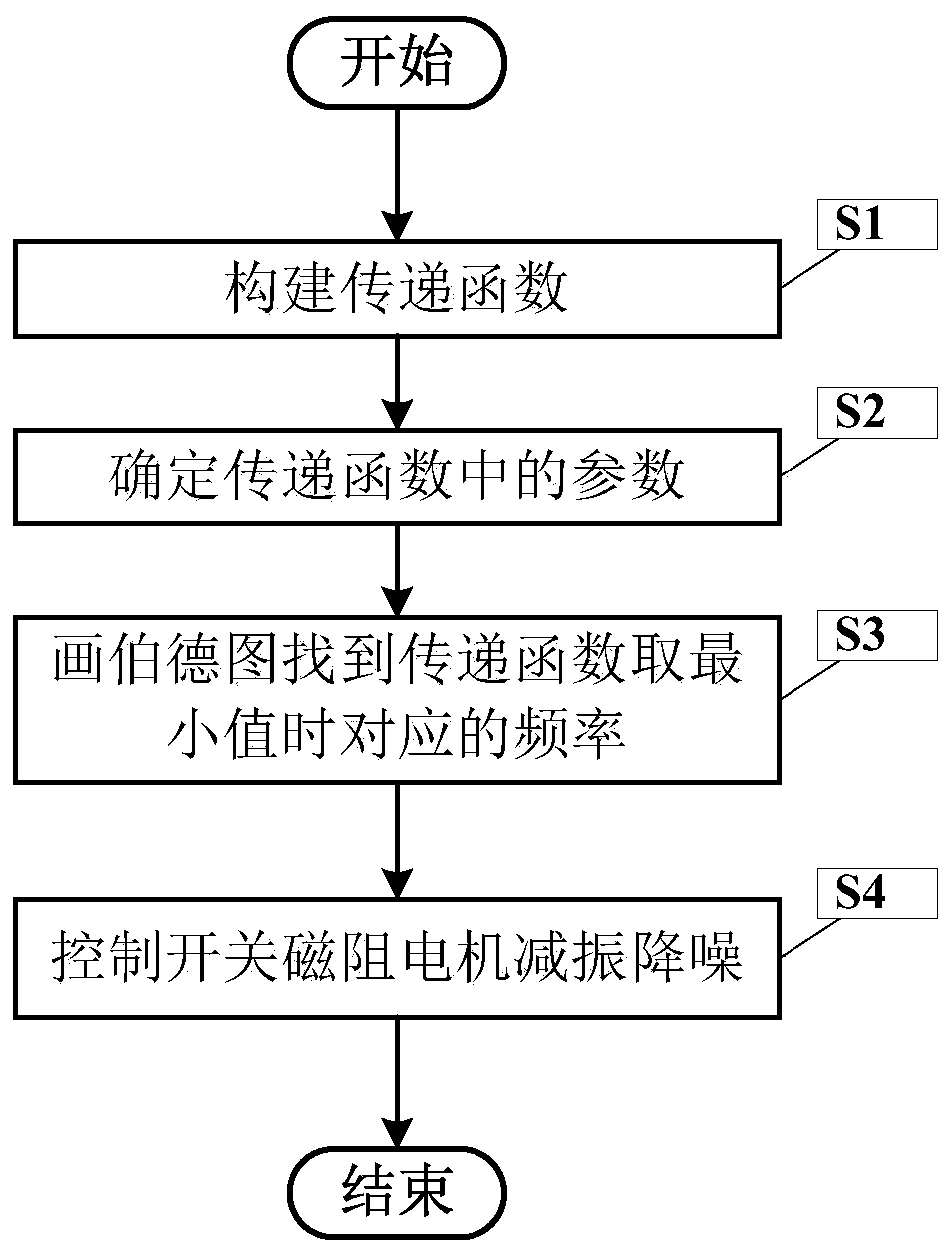

[0035] figure 1 It is a flow chart of the vibration reduction and noise reduction method of the switched reluctance motor based on the structural characteristics of the motor in the present invention.

[0036] In this example, if figure 1 As shown, a method for reducing vibration and noise of a switched reluctance motor based on the structural characteristics of the motor in the present invention comprises the following steps:

[0037] S1, build the transfer function H (s) between the vibration acceleration a (s) of the switched reluctance motor stator and the radial force F (s);

[0038]

[0039] Among them, i represents different modal orders, n is the lowest modal order, m is the highest modal order; ω i is the natural angular frequency of the i-order mode, ω i =2πf i , f i is the natural frequency of the i-order mode; ξ i is the damping ratio of the i-order mode; A i is the gain of the transfer function in the i-order mode; s is the Laplace variable;

[0040] S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com