Preparation method of glutinous rice flour

A technology of glutinous rice flour and glutinous rice starch, which is applied in food science and other fields to achieve the effects of improving sensory quality, reducing cooking loss, and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

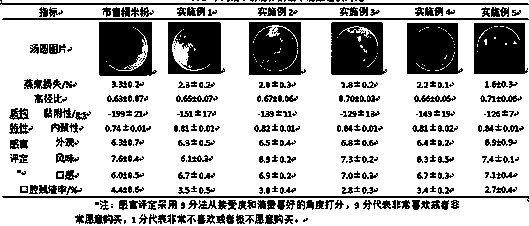

Embodiment 1

[0019] Take the glutinous rice raw material, remove impurities, soak in water, adjust the ratio of solid to liquid to 1:2, and soak for 60 min at 25 °C. After soaking, the glutinous rice was crushed by wet method, and the average particle size (D50) of the crushed rice pulp was 10 μm. Adjust the concentration of crushed rice milk to 15%, select the type of protease as acid protease, use dilute hydrochloric acid solution to adjust the pH value of rice milk, and standardize the rice milk according to its optimum reaction conditions. After the reaction, the protease in rice milk Inactivation terminates the reaction. Cyclone separation equipment is used to control the underflow pressure and overflow pressure in the cyclone separation operation, the adjustment range is 0.1~0.8 MPa, and the reacted rice slurry is separated into two types of deep-processing products: glutinous rice starch and protein modified glutinous rice flour. The protein dry basis content in glutinous rice star...

Embodiment 2

[0021] Take the glutinous rice raw material, remove impurities, soak in water, adjust the ratio of solid to liquid to 1:3, and soak for 50 min at 35 °C. After soaking, the glutinous rice was pulverized by wet method, and the average particle size (D50) of the pulverized rice pulp was 7 μm. Adjust the concentration of crushed rice milk to 20%, select the type of protease as neutral protease, standardize the rice milk according to its optimal reaction conditions, and inactivate the protease in the rice milk to terminate the reaction after the reaction. Cyclone separation equipment is used to control the underflow pressure and overflow pressure in the cyclone separation operation, the adjustment range is 0.1~0.8 MPa, and the reacted rice slurry is separated into two types of deep-processing products: glutinous rice starch and protein modified glutinous rice flour. The protein dry basis content in glutinous rice starch and protein-modified glutinous rice flour was determined to be...

Embodiment 3

[0023] Take the glutinous rice raw material, remove impurities, soak in water, adjust the ratio of solid to liquid to 1:5, and soak at 45 °C for 40 min. After soaking, the glutinous rice was pulverized by wet method, and the average particle size (D50) of the pulverized rice pulp was 5 μm. Adjust the concentration of rice milk after pulverization to 25%, select the type of protease as alkaline protease, use dilute sodium hydroxide solution to adjust the pH value of rice milk, and standardize the rice milk according to its optimum reaction conditions. The protease inactivation terminated the reaction. Cyclone separation equipment is used to control the underflow pressure and overflow pressure in the cyclone separation operation, the adjustment range is 0.1~0.8 MPa, and the reacted rice slurry is separated into two types of deep-processing products: glutinous rice starch and protein modified glutinous rice flour. The protein dry basis content in glutinous rice starch and protei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap