Fine dried noodles and production method thereof

A technology of dried noodles and flour flocs, which is applied in food science, food ingredients, food drying, etc., can solve problems affecting gluten protein denaturation and starch gelatinization rate, slow water diffusion rate, unfavorable heat transfer of products, etc., to reduce noodle breakage The effects of bar rate, fast water loss and fast heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

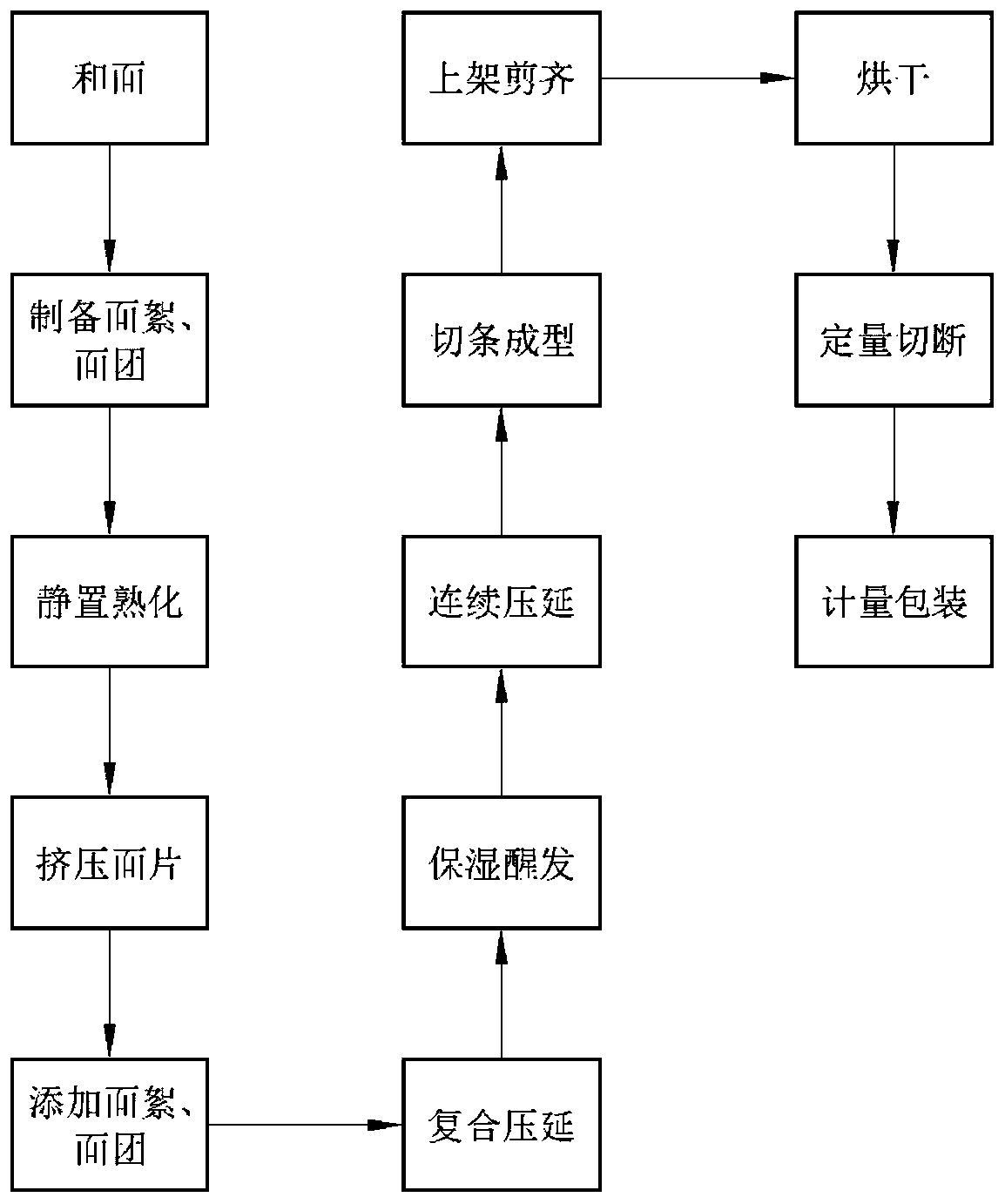

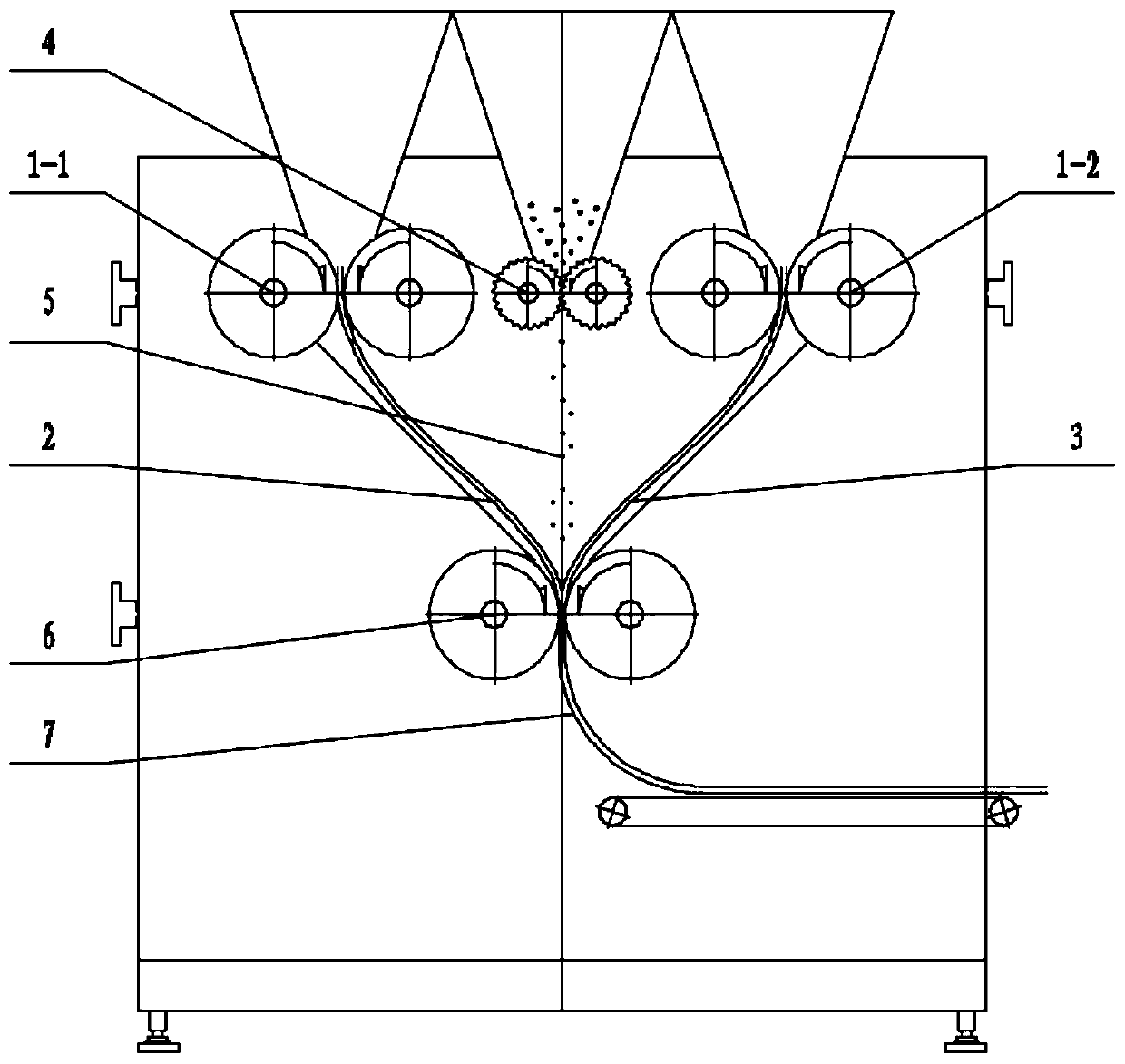

[0045] A preparation method for dried noodles, comprising the steps of:

[0046](1) Kneading dough: Dissolve edible salt and edible alkali in water, atomize salt water, and gradually spray into wheat flour for dough mixing; the ratio of flour and water can be adjusted according to the type of flour.

[0047] The mixed dough or flour flocs are in the form of granules, with uniform and sufficient water absorption, suitable gluten expansion, loose granules, and no raw powder.

[0048] In this embodiment, the temperature of the dough or flour wadding output from the outlet of the dough mixer is 25° C., and the water content is 40%.

[0049] (2) Preparation of flour wadding: Flour, water, edible salt and other auxiliary materials are used to prepare flour wadding separately in a dough mixer. In this embodiment, the temperature of the flour wadding output from the outlet of the dough mixer is 25° C., and the water content is 30%.

[0050] (3) Static curing: the dough or flour wadd...

Embodiment 2

[0076] In the step (3), the present invention carries out low-speed agitation, proofing and ripening of the mixed flour flocs at normal temperature, breaks and agglomerates, eliminates the internal stress of the flour flocs, stabilizes the internal structure of the flour flocs, and stabilizes the next tableting process. Play the role of uniform feeding.

[0077] All the other steps are the same as in Example 1.

Embodiment 3

[0079] In the present invention, the flour wadding is further fermented before the flour wadding is added in step (5), so as to generate more air bubbles and air gaps. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com